|

Jun 14, 2014 - 10:08 PM Jun 14, 2014 - 10:08 PM

|

|

|

Enthusiast   Joined Apr 24, '14 From Durham, NC, USA Currently Offline Reputation: 0 (0%) |

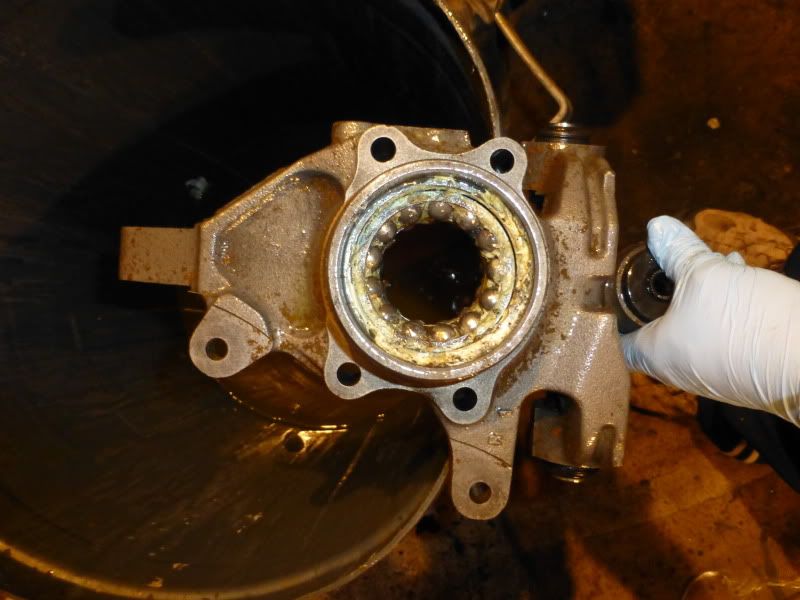

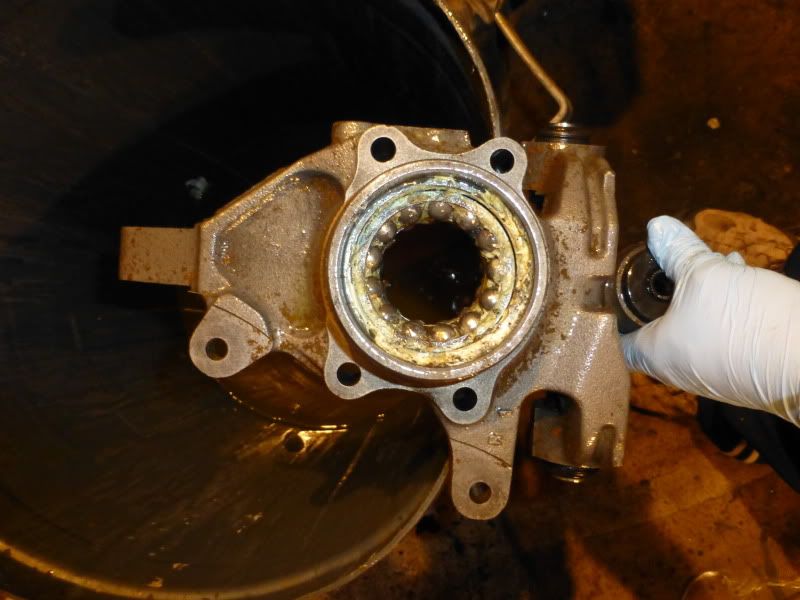

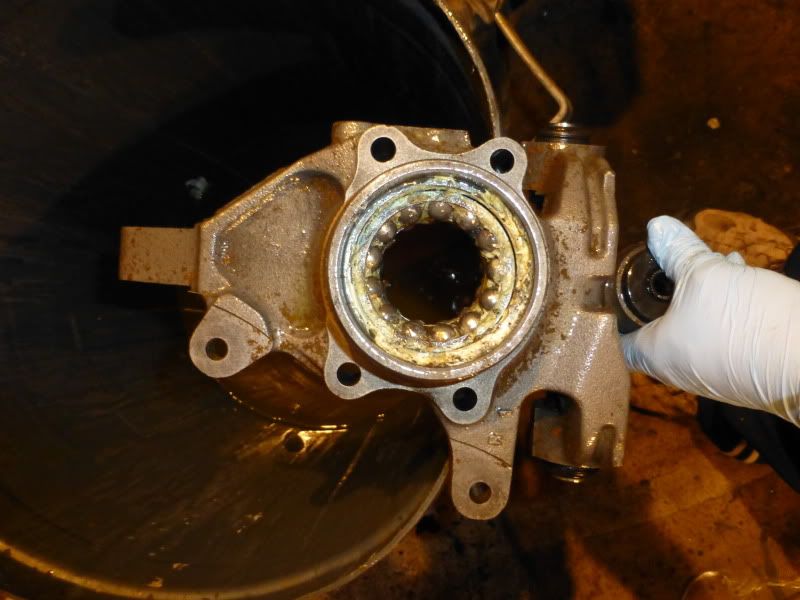

I picked off a steering knuckle from a junkyard Celica, removed the ball joint and wheel bearing, and cleaned it with a wire wheel to the point where it seems rust and yuck free. Now it is almost all bare metal and I have two questions:

1) What is the best/easiest way to remove the remaining rust? (I don't have a sand blaster.) 2) What is a good/long-lasting way to protect the bare metal from rusting again? To show what I am talking about I include a photo of the newly cleaned SN next to my Celica's SN (the one with with bent ears). The junkyard SN is the lighter of the two, the golden rust colored one; it came from a red 1995 Celica and is going on a white 1994 Celica:  Thanks to anyone who takes time to help me by discussing these questions. |

Jun 14, 2014 - 10:58 PM Jun 14, 2014 - 10:58 PM

|

|

|

Enthusiast      Joined Mar 15, '07 From Tennessee Currently Offline Reputation: 52 (100%) |

Dip in phosphorus?.. Powdercoating is best. Go to eastwood. I use chassis paint in my rears

-------------------- Learned a lot in 10 years... I hardly log in anymore, last login Today Sept 6 2019, and I was forced just to clarify a post. LOL

If you PM me and I dont respond, dont fret or cry. Im alive, better post your questions in the thread below, maybe I log back in 2grfe Swapped... Why I chose the 2GR, before you ask read here... A great civilization is not conquered from without until it has destroyed itself from within. @llamaraxing in Instagram is the best way to find me. I hardly log here anymore. |

Jun 14, 2014 - 11:04 PM Jun 14, 2014 - 11:04 PM

|

|

|

Enthusiast      Joined Mar 15, '07 From Tennessee Currently Offline Reputation: 52 (100%) |

-------------------- Learned a lot in 10 years... I hardly log in anymore, last login Today Sept 6 2019, and I was forced just to clarify a post. LOL

If you PM me and I dont respond, dont fret or cry. Im alive, better post your questions in the thread below, maybe I log back in 2grfe Swapped... Why I chose the 2GR, before you ask read here... A great civilization is not conquered from without until it has destroyed itself from within. @llamaraxing in Instagram is the best way to find me. I hardly log here anymore. |

Jun 14, 2014 - 11:38 PM Jun 14, 2014 - 11:38 PM

|

|

|

Enthusiast   Joined Apr 24, '14 From Durham, NC, USA Currently Offline Reputation: 0 (0%) |

Dip in phosphorus?.. Powdercoating is best. Go to eastwood. I use chassis paint in my rears In what product would I find the phosphorus? I thought that was a dangerous chemical element because of its high reactivity; remember HS chemistry class being shown how rapidly it burned when exposed to oxygen. Is "dipping" in phosphorus a DIY job? I'm going to have to do some research (tomorrow) on powdercoating; have zero experience with it. Have heard people talking about it but know nothing. Eastwood is the name of an auto paint company, right? And I'm also guessing the "chassis paint" is an Eastwood product? I saw your photos. The black is fine with me and I'm assuming that "chassis paint" must be a long lasting coating. Do local auto stores carry Eastwood products? Do you spray paint and if so how do you do it? I've been using cans. Very much appreciate your taking time to address my questions. |

Jun 15, 2014 - 12:13 AM Jun 15, 2014 - 12:13 AM

|

|

|

Enthusiast      Joined Feb 23, '12 From Warrior, AL Currently Offline Reputation: 0 (0%) |

Coca~Cola=carbonic acid and phosphoric acid. Vinegar is acetic acid and works on rust as well, but is a little harsher than the cola.

-------------------- 2001 Miata LS 5-speed

|

Jun 15, 2014 - 2:36 AM Jun 15, 2014 - 2:36 AM

|

|

Enthusiast    Joined Aug 25, '08 From England Currently Offline Reputation: 1 (100%) |

Best thing to do, buy some "bilt hamber Deox c" this is a very effective rust remover, it will remove all remaining traces of rust, here's the hub carrier I soaked in Deox c for a few days, no other work was done on it at this stage,, no wire brushing, nothing

I also tried phosphoric acid but you have to wash it off which seems a bit odd as it reintroduces rust, if you want to go really over board you can get it zinc plated. After removing the rust I agree with the Eastwood comment. It's a very good paint, they do something called chassis Black extreme in either a spray can (very expensive) or tin to use a brush with, I tried both, both work well. Leave it to dry for at least a week to reach maximum toughness before putting it onto the car (if you can leave it that long) remember to go for the extreme version, they do a chassis black that's not as tough. You can also buy something called Epoxy mastic 121 from a company called rust busters, it's a two pack paint, extremely tough, used to paint the legs of oil rigs apparently! The finish isn't as smooth as the Eastwood paint but it's as hard as nails. Powder coating I am not so tempted by, I did some tests years ago and as soon as the powder coating gets chipped it allowed water to get between the powder coat and the metal. It depends greatly on the quality of the powder coater, some are very good and produce a very tough finish that's nearly impossible to chip, some don't. So it's a bit of hit and miss. Another option is something called POR15, they do a two pack anti rust paint that's pretty good, the finish is excellent, no matter how badly you apply it, it dries with a glass smooth high gloss finish, but it's not UV resistant so needs a top coat, they also do something called a hardnose paint, again a two pack paint, I used this on my fuel tank, the finish is OK but you can belt it with a hammer and it doesn't chip, very strong, very expensive. -------------------- |

Jun 15, 2014 - 2:50 AM Jun 15, 2014 - 2:50 AM

|

|

|

Enthusiast      Joined Feb 23, '12 From Warrior, AL Currently Offline Reputation: 0 (0%) |

The last option is just to move further south.

-------------------- 2001 Miata LS 5-speed

|

Jun 15, 2014 - 9:50 AM Jun 15, 2014 - 9:50 AM

|

|

|

Enthusiast   Joined Apr 24, '14 From Durham, NC, USA Currently Offline Reputation: 0 (0%) |

Best thing to do, buy some "bilt hamber Deox c" this is a very effective rust remover, it will remove all remaining traces of rust, here's the hub carrier I soaked in Deox c for a few days, no other work was done on it at this stage,, no wire brushing, nothing  I also tried phosphoric acid but you have to wash it off which seems a bit odd as it reintroduces rust, if you want to go really over board you can get it zinc plated. After removing the rust I agree with the Eastwood comment. It's a very good paint, they do something called chassis Black extreme in either a spray can (very expensive) or tin to use a brush with, I tried both, both work well. Leave it to dry for at least a week to reach maximum toughness before putting it onto the car (if you can leave it that long) remember to go for the extreme version, they do a chassis black that's not as tough. You can also buy something called Epoxy mastic 121 from a company called rust busters, it's a two pack paint, extremely tough, used to paint the legs of oil rigs apparently! The finish isn't as smooth as the Eastwood paint but it's as hard as nails. Powder coating I am not so tempted by, I did some tests years ago and as soon as the powder coating gets chipped it allowed water to get between the powder coat and the metal. It depends greatly on the quality of the powder coater, some are very good and produce a very tough finish that's nearly impossible to chip, some don't. So it's a bit of hit and miss. Another option is something called POR15, they do a two pack anti rust paint that's pretty good, the finish is excellent, no matter how badly you apply it, it dries with a glass smooth high gloss finish, but it's not UV resistant so needs a top coat, they also do something called a hardnose paint, again a two pack paint, I used this on my fuel tank, the finish is OK but you can belt it with a hammer and it doesn't chip, very strong, very expensive. You've been quite thorough in your explanation, and I especially thank you for that. Much appreciated. Seems you've done a lot of homework on how to protect the parts you restore and I admire the thought and experimentation you have put into it. Your photo shows a steering knuckle (hub carrier) that you simply dumped into a chemical bath, without any other preparation, and the result is amazing. In my case, I have already used a strong wire wheel in an angle grinder to spin off the debris. That did a fast and pretty reasonable job and the metal didn't seem any the worse for the violence. As you can see, the amount of rust remaining is way less than before I started. Knowing that, would you still recommend a bath in Deox C, meaning, is the quality of the resulting metal surface finish worth the cost of the chemical? Also, just to check my thinking, when it is finally clean I guess that's the time to reinstall the wheel bearing and ball joint, i.e., prior to painting because installation of the bearing, etc, would be rough on the paint. I am concerned about the quality of the work I am doing, but at the same time know that nothing is permanent, and after all, it's a steering knuckle, a part that is rarely seen, so do believe that a coating designed for marine applications is indeed "going overboard." |

Jun 15, 2014 - 10:05 AM Jun 15, 2014 - 10:05 AM

|

|

|

Enthusiast   Joined Apr 24, '14 From Durham, NC, USA Currently Offline Reputation: 0 (0%) |

The last option is just to move further south. The changes in climate during my lifetime have already made North Carolina feel like Alabama, or upper Florida before. There are many days of the year with high relative humidity. And the number of days we pass through dew point seems to be lengthening; I dare not leave any expensive metallic tools in my shed over winter. I live far enough south to be almost free of road salt in the winter; nice snow-storms are a thing of the past. I really don't see the benefit of moving still farther south to take on even more heat and humidity. If you had suggested "out west," maybe in the desert where there isn't any wetness at all, ok. |

Jun 15, 2014 - 11:10 AM Jun 15, 2014 - 11:10 AM

|

|

Enthusiast    Joined Aug 25, '08 From England Currently Offline Reputation: 1 (100%) |

Best thing to do, buy some "bilt hamber Deox c" this is a very effective rust remover, it will remove all remaining traces of rust, here's the hub carrier I soaked in Deox c for a few days, no other work was done on it at this stage,, no wire brushing, nothing  I also tried phosphoric acid but you have to wash it off which seems a bit odd as it reintroduces rust, if you want to go really over board you can get it zinc plated. After removing the rust I agree with the Eastwood comment. It's a very good paint, they do something called chassis Black extreme in either a spray can (very expensive) or tin to use a brush with, I tried both, both work well. Leave it to dry for at least a week to reach maximum toughness before putting it onto the car (if you can leave it that long) remember to go for the extreme version, they do a chassis black that's not as tough. You can also buy something called Epoxy mastic 121 from a company called rust busters, it's a two pack paint, extremely tough, used to paint the legs of oil rigs apparently! The finish isn't as smooth as the Eastwood paint but it's as hard as nails. Powder coating I am not so tempted by, I did some tests years ago and as soon as the powder coating gets chipped it allowed water to get between the powder coat and the metal. It depends greatly on the quality of the powder coater, some are very good and produce a very tough finish that's nearly impossible to chip, some don't. So it's a bit of hit and miss. Another option is something called POR15, they do a two pack anti rust paint that's pretty good, the finish is excellent, no matter how badly you apply it, it dries with a glass smooth high gloss finish, but it's not UV resistant so needs a top coat, they also do something called a hardnose paint, again a two pack paint, I used this on my fuel tank, the finish is OK but you can belt it with a hammer and it doesn't chip, very strong, very expensive. You've been quite thorough in your explanation, and I especially thank you for that. Much appreciated. Seems you've done a lot of homework on how to protect the parts you restore and I admire the thought and experimentation you have put into it. Your photo shows a steering knuckle (hub carrier) that you simply dumped into a chemical bath, without any other preparation, and the result is amazing. In my case, I have already used a strong wire wheel in an angle grinder to spin off the debris. That did a fast and pretty reasonable job and the metal didn't seem any the worse for the violence. As you can see, the amount of rust remaining is way less than before I started. Knowing that, would you still recommend a bath in Deox C, meaning, is the quality of the resulting metal surface finish worth the cost of the chemical? Also, just to check my thinking, when it is finally clean I guess that's the time to reinstall the wheel bearing and ball joint, i.e., prior to painting because installation of the bearing, etc, would be rough on the paint. I am concerned about the quality of the work I am doing, but at the same time know that nothing is permanent, and after all, it's a steering knuckle, a part that is rarely seen, so do believe that a coating designed for marine applications is indeed "going overboard." Using the Deox c is up to you, it will remove all traces of rust, it comes as a powder and you mix it into warm water for the amount you need, it's not that expensive but maybe not worth the fuss if you have already taken most of the rust off....but it depends how thorough you want to be, as you say it's a Hub and will be pounded by gravel and stones from the road. I have painted mine before putting the bearing back in which I might live to regret, putting it back in before paint might be a worthy exercise to protect the paint from damage, the hub won't really get in the way of applying the paint. -------------------- |

Jun 15, 2014 - 11:42 AM Jun 15, 2014 - 11:42 AM

|

|

|

Enthusiast      Joined Feb 23, '12 From Warrior, AL Currently Offline Reputation: 0 (0%) |

The last option is just to move further south. The changes in climate during my lifetime have already made North Carolina feel like Alabama, or upper Florida before. There are many days of the year with high relative humidity. And the number of days we pass through dew point seems to be lengthening; I dare not leave any expensive metallic tools in my shed over winter. I live far enough south to be almost free of road salt in the winter; nice snow-storms are a thing of the past. I really don't see the benefit of moving still farther south to take on even more heat and humidity. If you had suggested "out west," maybe in the desert where there isn't any wetness at all, ok. Humidity is a bitch. Still, I've never had a problem with rust on cars that have lived in Alabama their entire lives. Move out to Arizona, I hear the dry heat is good for you. -------------------- 2001 Miata LS 5-speed

|

Jun 15, 2014 - 11:46 AM Jun 15, 2014 - 11:46 AM

|

|

|

Enthusiast      Joined Mar 15, '07 From Tennessee Currently Offline Reputation: 52 (100%) |

eastwood. cheaper in home depot  so many products in my picture you see the chassis black extreme, chip resistant and brake fluid resistant. powdercoating is better, i dont have tools, nor do i want to pay a lot... -------------------- Learned a lot in 10 years... I hardly log in anymore, last login Today Sept 6 2019, and I was forced just to clarify a post. LOL

If you PM me and I dont respond, dont fret or cry. Im alive, better post your questions in the thread below, maybe I log back in 2grfe Swapped... Why I chose the 2GR, before you ask read here... A great civilization is not conquered from without until it has destroyed itself from within. @llamaraxing in Instagram is the best way to find me. I hardly log here anymore. |

Jun 15, 2014 - 12:48 PM Jun 15, 2014 - 12:48 PM

|

|

|

Enthusiast   Joined Apr 24, '14 From Durham, NC, USA Currently Offline Reputation: 0 (0%) |

eastwood. cheaper in home depot  so many products in my picture you see the chassis black extreme, chip resistant and brake fluid resistant. powdercoating is better, i dont have tools, nor do i want to pay a lot... So many products is right. Spent my morning visiting places, looking for the Deox-C and Eastwood paints. At Home Depot the paint fellow told me they did not carry Eastwood, nor did they have Deox-C, but did have other auto spray paints, most by RUSTOLEUM, and a rust eliminator made by KRUD CUTTER. Didn't buy anything. Went to Advance Auto. They didn't carry Eastwood paints or Deox-C. While I was asking about rust removers at Advance Auto, I stumbled into a chatty fellow who said that NAVAL JELLY (now owned by LOCTITE) was just the thing I needed. Claimed he had been a mechanic in the air force for a long time and worked on various high performance Jets, including a lot of rust removal, knew that NAVAL JELLY was a very good product, so long as you kept the reaction out of the reach of oxygen by putting the coated parts in a squeezed down zip-lock or equivalent. Then he went on and identified the more than a dozen classic cars he has bought and restored (including three Porches), but never could bring himself to sell any of them! Offered me the use of his sand blaster whenever I needed! Turns out he lives within a mile of me and spends many hours down as the LKQ junkyard! Maybe we are birds of a feather?. . . maybe an American Eagle and a sparrow. . . My wife outside in the Tacoma was waiting on me so I was trying to cut the conversation short (we did have frozen foods in the back), yet I was excited by talking with this guy, so as I was saying good bye to him, I just left the store with the bottle of LOCTITE NAVAL JELLY in my hand, and didn't realize I hadn't paid for it till we were almost home and noticed a police car driving right behind me. Just phoned that branch of Advance Auto and turned myself in! BTW: Would that "Prep & Etch" phosphoric soln be the best thing for my case, or is the Naval Jelly good enough just before painting? Went and read all the info on the HD website, and it seems like it would do the job, and I have some other, smaller parts that could use what's left of it when I finish. This post has been edited by Langing: Jun 15, 2014 - 1:10 PM |

Jun 15, 2014 - 3:00 PM Jun 15, 2014 - 3:00 PM

|

|

|

Enthusiast      Joined Feb 23, '12 From Warrior, AL Currently Offline Reputation: 0 (0%) |

Well. as long as you didn't take $50+ worth of Naval Jelly it's only a minor offence. I've heard good things about it Naval Jelly before, so hopefully it does the job for you.

This post has been edited by Box: Jun 15, 2014 - 3:02 PM -------------------- 2001 Miata LS 5-speed

|

Jun 15, 2014 - 4:38 PM Jun 15, 2014 - 4:38 PM

|

|

|

Enthusiast   Joined Apr 24, '14 From Durham, NC, USA Currently Offline Reputation: 0 (0%) |

Well. as long as you didn't take $50+ worth of Naval Jelly it's only a minor offence. I've heard good things about it Naval Jelly before, so hopefully it does the job for you. Actually, on njccmd2002s advice, I read up on the "Phosphoric Prep and Etch" product that is available at my local Home Depot (including the few on-line reviews) and decided to take the Naval Jelly back and buy this other product instead (yeah, I know how that sounds). When the gentleman was describing how Naval Jelly works, he explained how careful you have to be to NOT let it become dry while doing its work, and how messy things can get if you do. Since I have never used it before, I'm automatically at a disadvantage; by Murphy's Law, it would perform at its worst for me. The description and reviews for this other product seem to say that it does its thing very well. Hopefully, it will do the job for me. Here is a question for you, if you know off the top of your head. How do I transition from bathing the part in the solution to putting on the paint? Is there an intermediate step? I'm assuming there are instructions on the product itself, but if you happen to know something from your experience, I would certainly like to hear it. |

Jun 15, 2014 - 6:11 PM Jun 15, 2014 - 6:11 PM

|

|

|

Enthusiast      Joined Feb 23, '12 From Warrior, AL Currently Offline Reputation: 0 (0%) |

According to the instructions you rinse or wipe it with a damp cloth to remove any residue and then paint within 48 hours. Could wipe with denatured alcohol, then do your paint of choice for bare metals.

-------------------- 2001 Miata LS 5-speed

|

Jun 15, 2014 - 6:54 PM Jun 15, 2014 - 6:54 PM

|

|

|

Enthusiast   Joined Apr 24, '14 From Durham, NC, USA Currently Offline Reputation: 0 (0%) |

According to the instructions you rinse or wipe it with a damp cloth to remove any residue and then paint within 48 hours. Could wipe with denatured alcohol, then do your paint of choice for bare metals. TX. . . that is very helpful. Hope I can return the favor some day. |

Jun 16, 2014 - 1:17 AM Jun 16, 2014 - 1:17 AM

|

|

Enthusiast     Joined Oct 29, '11 From Haltom City, Texas Currently Offline Reputation: 1 (100%) |

Rust converting primer is available at most autoparts stores, follow with any cheap spraypaint or the same brand as the primer for best results. Getting the rust off isnt a concern, its getting the paint to adhere. As long as the paint is intact, water wont get to the metal and the rust will cease to grow.

You could just get lazy, coat the whole thing in rubberized undercoating, and call it a day. Unless you plan on constantly climbing under your car and wiping down the suspension by hand it will inevitably get greasy and grimy. Any paint out of a rattlecan cant be expected to last forever either, its just a matter of months or years before it oxidizes or succumbs to some kind of chemical breakdown. Older cars were actually manufactured with a rust inhibiting system, slow oil leaks. The grimy aftermath eventually coats everything under the car and creates a water/rust proof barrier This post has been edited by Special_Edy: Jun 16, 2014 - 1:32 AM |

Jun 17, 2014 - 2:44 PM Jun 17, 2014 - 2:44 PM

|

|

|

Enthusiast   Joined Apr 24, '14 From Durham, NC, USA Currently Offline Reputation: 0 (0%) |

eastwood. cheaper in home depot  so many products in my picture you see the chassis black extreme, chip resistant and brake fluid resistant. powdercoating is better, i dont have tools, nor do i want to pay a lot... I'm using your suggestion, the Phosphoric Acid Prep and Etch from Home Depot. Brushed it on a couple hours ago and will probably wipe it off later this afternoon. When I went back to see your photo of your paint job it looks like you painted all metal surfaces, including all flats where the metal of the steering knuckle meets mounting brackets. I had been thinking of masking those mating surfaces so they didn't get painted. There are a couple of reasons for thinking this way. One is making sure that parts are able to fit together without any restriction. Another is electrical conduction pathways. If there is paint, it might not permit a metal to metal connection, so no conduction path, say back to the battery as ground, or supposing lightening strikes. When I painted my caliper mounting bracket I painted those surfaces, then when I discovered that the rotor was dragging on the bracket I wished I had not painted the mounting surfaces and ground them back clean. Which is right? I need to paint within 48 hours. |

Jun 17, 2014 - 6:19 PM Jun 17, 2014 - 6:19 PM

|

|

|

Enthusiast      Joined Mar 15, '07 From Tennessee Currently Offline Reputation: 52 (100%) |

if lighting strikes, it wont strike the hub, it will strike the metal of the car, or ground, in which case your tires are rubber.

when i fitted my hubs, you have to remember that the struts are painted, too. in any case, the more exposed metal you have the rust potential. my strut bolts to hub were so affected with rust, it was crazy, any ways i always use  it will guarantee me that i wont fight with rust again -------------------- Learned a lot in 10 years... I hardly log in anymore, last login Today Sept 6 2019, and I was forced just to clarify a post. LOL

If you PM me and I dont respond, dont fret or cry. Im alive, better post your questions in the thread below, maybe I log back in 2grfe Swapped... Why I chose the 2GR, before you ask read here... A great civilization is not conquered from without until it has destroyed itself from within. @llamaraxing in Instagram is the best way to find me. I hardly log here anymore. |

|

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: January 13th, 2026 - 12:02 AM |