Mar 3, 2007 - 10:48 PM Mar 3, 2007 - 10:48 PM

|

|

Enthusiast      Joined Jun 1, '03 From WV Currently Offline Reputation: 2 (100%) |

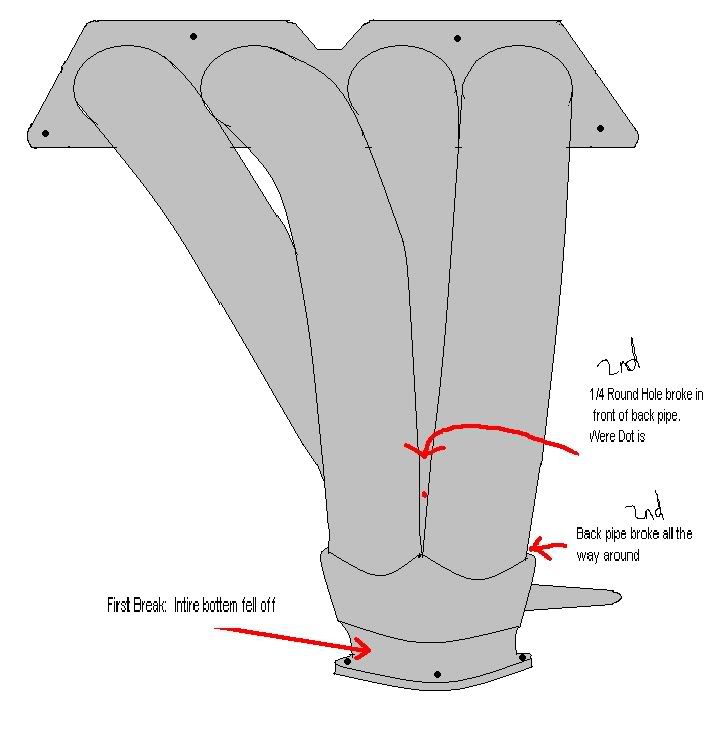

My dang header broke again. This is the 2nd time. 1st time it broke at the collector and the down pipe just fell off. That was an easy fix because I could get all the way around it. This time the back 2 pipes and the front passenger side pipes cracked. There was a quarter inch round hole out of back drivers side pipe too. And it was in the front of it. I could not get to that thing. My dad and I spent about 5 hours screwing around with it trying to get to it. Welder, torch, and melted brass ended up kind of fixing it. There is still a little hole, but it's not noticeable audibly. My dad and I figured that what caused it was the heat tape keeping the pipe too hot and the baffle holding the flow up too much also making it hot. I ran it hard for about 20 min and it was cracked with I stopped. The fact that it didn't have a brace didn't help, so we welded a nice one on. So if you have a header, put a brace of it and watch the temp of it.

-------------------- Live Free, Be Happy

|

|

Replies

(1 - 9)

Mar 3, 2007 - 11:21 PM Mar 3, 2007 - 11:21 PM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

ya, the header you have is chromed mild steel i think. thats ****ty its broken soo fast, why didnt you take it off to repair it? btw that brazing wont hold as well as a good tig weld will.

-------------------- |

Mar 3, 2007 - 11:31 PM Mar 3, 2007 - 11:31 PM

|

|

|

Enthusiast      Joined Jun 14, '05 Currently Offline Reputation: 1 (100%) |

Yep heat tape is bad.. all it does is make the metal more fragile due to the collected heat..

|

Mar 4, 2007 - 10:33 AM Mar 4, 2007 - 10:33 AM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

QUOTE(jdg371 @ Mar 3, 2007 - 11:31 PM) [snapback]532604[/snapback] Yep heat tape is bad.. all it does is make the metal more fragile due to the collected heat.. its not as bad on stainless steel, ive had my ebay header on for several months longer than he's had his, had mine wrapped for several months longer than his, and have had no problems, poor header quality has as much to do with it. -------------------- |

Mar 4, 2007 - 2:07 PM Mar 4, 2007 - 2:07 PM

|

|

|

Enthusiast      Joined Jan 28, '05 From Redondo Beach, CA Currently Offline Reputation: 86 (100%) |

my chrome header still is doing fine, i wrapped it with dei wrap not cheap stuff

--------------------  |

Mar 4, 2007 - 3:54 PM Mar 4, 2007 - 3:54 PM

|

|

Enthusiast      Joined May 15, '05 From Toronto Currently Offline Reputation: 4 (100%) |

QUOTE(jdg371 @ Mar 3, 2007 - 11:31 PM) [snapback]532604[/snapback] Yep heat tape is bad.. all it does is make the metal more fragile due to the collected heat.. I use the DEI heat wrap and my headers are fine. I need to use the heat tape because i was gettin so much excessive heat that if it was below 15degrees celcius, my front window would fog up. QUOTE(LewFX @ Mar 4, 2007 - 2:07 PM) [snapback]532739[/snapback] my chrome header still is doing fine, i wrapped it with dei wrap not cheap stuff I use the DEI stuff to and it works great, mind u i got the pacesetter ceramic coated headers. Mine were never chromed and im the second owner on them. You got any pictures of how yours failed bulldog? |

Mar 4, 2007 - 6:21 PM Mar 4, 2007 - 6:21 PM

|

|

Enthusiast      Joined Jun 1, '03 From WV Currently Offline Reputation: 2 (100%) |

QUOTE(Bitter @ Mar 3, 2007 - 11:21 PM) [snapback]532597[/snapback] ya, the header you have is chromed mild steel i think. thats ****ty its broken soo fast, why didnt you take it off to repair it? btw that brazing wont hold as well as a good tig weld will. It's not chrome. It's custom, 2 were made. I've had it for a good 9 months now. I use the DEI tape. I still have it on the top of the header. The bottem is uncovered and I welded some bolts to it and made a heat sheald to keep from melting my fans. Probably wouldn't melt them, but it's better to be sure. I know that the brass won't hold like a good tig weld. A good tig will hold better than the mig weld I used. But I don't have a tig, and I've never tried to weld with that system either. It was a really tough spot to get to, and I had the header off the car. I had to get the wire to go down though a 1/8-1/4 inch wide gap down about 1.25 inches. It was like opperation. The wire kept hitting the sides and I couldn't get to the hole to weld it. It wasn't a great design. I'm designing a new one right now. It's a 4-2-1 design that will be easier to fix when it breaks. The 4-1 just isn't working for me. -------------------- Live Free, Be Happy

|

Mar 4, 2007 - 6:49 PM Mar 4, 2007 - 6:49 PM

|

|

Enthusiast      Joined Jun 1, '03 From WV Currently Offline Reputation: 2 (100%) |

-------------------- Live Free, Be Happy

|

Mar 5, 2007 - 12:36 AM Mar 5, 2007 - 12:36 AM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

sorry, i got you and LewFx confused. all you GT owners look the same :-p

what material did you make the header from? i think you'll like a 4-2-1 design better, what about a longer 4-1? remember to keep the firing order in mind, i think its 1342. so 1 and 3 should be together, 4 and 2 should be together. that way as the pulses travel down they'll pull the next down and pull air in during overlap. This post has been edited by Bitter: Mar 5, 2007 - 12:38 AM -------------------- |

Mar 5, 2007 - 8:01 AM Mar 5, 2007 - 8:01 AM

|

|

Enthusiast      Joined Jun 1, '03 From WV Currently Offline Reputation: 2 (100%) |

QUOTE(Bitter @ Mar 5, 2007 - 12:36 AM) [snapback]532910[/snapback] sorry, i got you and LewFx confused. all you GT owners look the same :-p what material did you make the header from? i think you'll like a 4-2-1 design better, what about a longer 4-1? remember to keep the firing order in mind, i think its 1342. so 1 and 3 should be together, 4 and 2 should be together. that way as the pulses travel down they'll pull the next down and pull air in during overlap. I didn't make the header. One was made for the seller and I offered to be a tester so one was made for me. I wasn't really happy with the survice or quallity of the product, so it didn't take off too well. It's not quite as stubby as I made it look in the picture, but it's not a long 4-1 design either. This is the design I have for it. I need to measure and get the pieces I need today. If I do the 1-3 and 4-2 firing order thing, it's going to need to have the Y pipes switched at the middle.

This post has been edited by Bigmeanbulldog55: Mar 5, 2007 - 7:20 PM -------------------- Live Free, Be Happy

|

|

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: January 18th, 2026 - 12:23 AM |