Mar 19, 2007 - 4:06 PM Mar 19, 2007 - 4:06 PM

|

|

|

Enthusiast      Joined Mar 31, '04 From Summerville, SC Currently Offline Reputation: 5 (100%) |

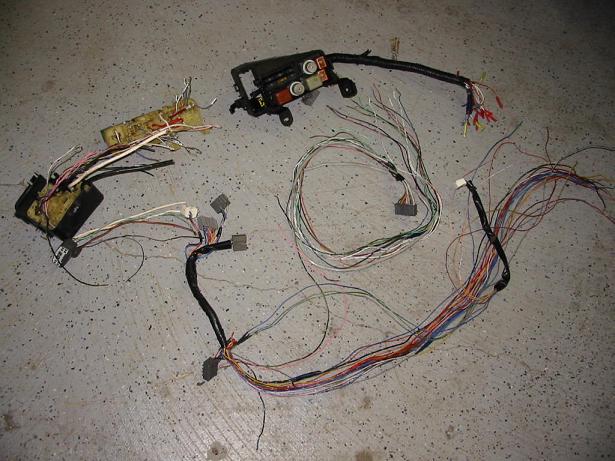

Stock exhaust we're replacing...

AngryMike fitting up the new stainless steel custom 3" mandrel bent tig-welded exhaust....          Custom tig-welded aluminum intercooler piping with welded-in flange for the Blitz BOV...   Working my magic with what that shop left of his wiring harness....   More to come soon!!! This post has been edited by Dr_Tweak: Mar 19, 2007 - 4:09 PM -------------------- -Dr Tweak, 6GC's resident engine swap wiring expert extraordinaire Click here to see my swaps drtweak@phoenixtuning.com |

|

Replies

Mar 20, 2007 - 9:16 PM Mar 20, 2007 - 9:16 PM

|

|

|

Enthusiast  Joined Mar 19, '07 From savannah Currently Offline Reputation: 0 (0%) |

QUOTE(Negative @ Mar 20, 2007 - 1:33 PM) [snapback]537958[/snapback] Welds look great. I welded for 3 years in college and I never got very good at tig because the place I worked for mainly speced mig welding. Just a thought: What makes Tig welding preferable in these applications? cosmetics, control and thinner materials make tig the best option. you get a much cleaner weld. you can weld stainless and aluminum with mig, however there is a lot of setup involved and the quality is pretty crappy in comparison. tig is a lot easyer and it looks great. This post has been edited by angrymike: Mar 20, 2007 - 9:23 PM |

Posts in this topic

Dr_Tweak Finishing up 2slow2nervous's 3SGTE Swap Mar 19, 2007 - 4:06 PM

Dr_Tweak Finishing up 2slow2nervous's 3SGTE Swap Mar 19, 2007 - 4:06 PM

WannabeGT4 Wow. That wiring is a mess. Why in the world did t... Mar 19, 2007 - 4:41 PM

WannabeGT4 Wow. That wiring is a mess. Why in the world did t... Mar 19, 2007 - 4:41 PM

Dr_Tweak QUOTE(WannabeGT4 @ Mar 19, 2007 - 9... Mar 19, 2007 - 4:44 PM

Dr_Tweak QUOTE(WannabeGT4 @ Mar 19, 2007 - 9... Mar 19, 2007 - 4:44 PM

presure2 welds look good!

harness looks like FUNNNN... Mar 19, 2007 - 5:07 PM

presure2 welds look good!

harness looks like FUNNNN... Mar 19, 2007 - 5:07 PM

Punch once again good job!!! Mar 19, 2007 - 5:26 PM

Punch once again good job!!! Mar 19, 2007 - 5:26 PM

brianforster no clocked turbo? tweaks gettin lazy!!... Mar 19, 2007 - 7:12 PM

brianforster no clocked turbo? tweaks gettin lazy!!... Mar 19, 2007 - 7:12 PM

Dr_Tweak Oh don't you worry, the clocked turbo is comin... Mar 19, 2007 - 9:31 PM

Dr_Tweak Oh don't you worry, the clocked turbo is comin... Mar 19, 2007 - 9:31 PM

toyotacrazy The piping looks great. Good luck with the harne... Mar 19, 2007 - 9:53 PM

toyotacrazy The piping looks great. Good luck with the harne... Mar 19, 2007 - 9:53 PM

angrymike hey guys, angrymike here. first time on this boar... Mar 19, 2007 - 10:59 PM

angrymike hey guys, angrymike here. first time on this boar... Mar 19, 2007 - 10:59 PM

snapshotgt QUOTE(DeW_H0e_GT @ Mar 22, 2007 - 12... Mar 22, 2007 - 12:10 AM

snapshotgt QUOTE(DeW_H0e_GT @ Mar 22, 2007 - 12... Mar 22, 2007 - 12:10 AM

Dr_Tweak Actually I just remembered, there's already an... Mar 20, 2007 - 8:12 AM

Dr_Tweak Actually I just remembered, there's already an... Mar 20, 2007 - 8:12 AM

Negative Welds look great. I welded for 3 years in college ... Mar 20, 2007 - 8:33 AM

Negative Welds look great. I welded for 3 years in college ... Mar 20, 2007 - 8:33 AM

2slow2nervous wow doc very nice work so far on my car!!... Mar 20, 2007 - 8:43 AM

2slow2nervous wow doc very nice work so far on my car!!... Mar 20, 2007 - 8:43 AM

x_itchy_b_x AngryMike those welds look very nice

I'd lik... Mar 20, 2007 - 10:25 AM

x_itchy_b_x AngryMike those welds look very nice

I'd lik... Mar 20, 2007 - 10:25 AM

easternpiro1 im so happy for you 2slow! now youre going to ... Mar 20, 2007 - 10:31 AM

easternpiro1 im so happy for you 2slow! now youre going to ... Mar 20, 2007 - 10:31 AM

2slow2nervous if i decide to drive her back which i really want ... Mar 20, 2007 - 10:37 AM

2slow2nervous if i decide to drive her back which i really want ... Mar 20, 2007 - 10:37 AM

Dr_Tweak QUOTE(2slow2nervous @ Mar 20, 2007 - 3... Mar 20, 2007 - 6:49 PM

Dr_Tweak QUOTE(2slow2nervous @ Mar 20, 2007 - 3... Mar 20, 2007 - 6:49 PM

2slow2nervous wow! thanks alot!!! u and ur whole... Mar 21, 2007 - 12:51 AM

2slow2nervous wow! thanks alot!!! u and ur whole... Mar 21, 2007 - 12:51 AM

Negative A long trip with a few stops for cool down is the ... Mar 20, 2007 - 1:49 PM

Negative A long trip with a few stops for cool down is the ... Mar 20, 2007 - 1:49 PM

2slow2nervous i would have about a 12 hour drive... so how many ... Mar 20, 2007 - 1:57 PM

2slow2nervous i would have about a 12 hour drive... so how many ... Mar 20, 2007 - 1:57 PM

gt_driFFter QUOTE(Negative @ Mar 20, 2007 - 3:49... Mar 21, 2007 - 9:10 PM

gt_driFFter QUOTE(Negative @ Mar 20, 2007 - 3:49... Mar 21, 2007 - 9:10 PM

lagos why was it a nightmare? Mar 20, 2007 - 6:43 PM

lagos why was it a nightmare? Mar 20, 2007 - 6:43 PM

Dr_Tweak Ask 2slow2nervous Mar 20, 2007 - 6:46 PM

Dr_Tweak Ask 2slow2nervous Mar 20, 2007 - 6:46 PM

99GT I want free things done to my car as well. I hate... Mar 20, 2007 - 7:26 PM

99GT I want free things done to my car as well. I hate... Mar 20, 2007 - 7:26 PM

Coomer Great work! That harness work doesn't look... Mar 21, 2007 - 11:17 AM

Coomer Great work! That harness work doesn't look... Mar 21, 2007 - 11:17 AM

InfamousChappy Y'all should do fab up some stainless manifold... Mar 21, 2007 - 12:16 PM

InfamousChappy Y'all should do fab up some stainless manifold... Mar 21, 2007 - 12:16 PM

zipstrips thoes welds are sexy! how thick is that IC pip... Mar 21, 2007 - 12:18 PM

zipstrips thoes welds are sexy! how thick is that IC pip... Mar 21, 2007 - 12:18 PM

Punisher and ten grand later..... Mar 21, 2007 - 8:17 PM

Punisher and ten grand later..... Mar 21, 2007 - 8:17 PM

playr158 when you rebuild a motor you should rebuild...

bu... Mar 21, 2007 - 9:30 PM

playr158 when you rebuild a motor you should rebuild...

bu... Mar 21, 2007 - 9:30 PM

MrBill QUOTE(playr158 @ Mar 21, 2007 - 9:30... Mar 21, 2007 - 11:02 PM

MrBill QUOTE(playr158 @ Mar 21, 2007 - 9:30... Mar 21, 2007 - 11:02 PM

Batman722 QUOTE(MrBill @ Mar 22, 2007 - 12:02 ... Mar 22, 2007 - 12:55 AM

Batman722 QUOTE(MrBill @ Mar 22, 2007 - 12:02 ... Mar 22, 2007 - 12:55 AM

gt_driFFter QUOTE(playr158 @ Mar 21, 2007 - 11:3... Mar 22, 2007 - 12:26 AM

gt_driFFter QUOTE(playr158 @ Mar 21, 2007 - 11:3... Mar 22, 2007 - 12:26 AM

Bitter its the first 100 miles that matter the most, that... Mar 21, 2007 - 10:59 PM

Bitter its the first 100 miles that matter the most, that... Mar 21, 2007 - 10:59 PM

DeW_H0e_GT wow great job!!!!....luv yoru work... Mar 22, 2007 - 12:04 AM

DeW_H0e_GT wow great job!!!!....luv yoru work... Mar 22, 2007 - 12:04 AM

tim86 hahaha thats funny... owned... good work tweak, aw... Mar 22, 2007 - 6:41 AM

tim86 hahaha thats funny... owned... good work tweak, aw... Mar 22, 2007 - 6:41 AM

alltracman78 RE: Finishing up 2slow2nervous's 3SGTE Swap Mar 22, 2007 - 6:58 AM

alltracman78 RE: Finishing up 2slow2nervous's 3SGTE Swap Mar 22, 2007 - 6:58 AM

2slow2nervous thanks for the info on breaking in the motor guys.... Mar 22, 2007 - 8:16 AM

2slow2nervous thanks for the info on breaking in the motor guys.... Mar 22, 2007 - 8:16 AM

x_itchy_b_x http://www.mototuneusa.com/break_in_secrets.htm

il... Mar 22, 2007 - 9:36 AM

x_itchy_b_x http://www.mototuneusa.com/break_in_secrets.htm

il... Mar 22, 2007 - 9:36 AM

Dr_Tweak Just so there's no mistake, "breaking in... Mar 22, 2007 - 9:41 AM

Dr_Tweak Just so there's no mistake, "breaking in... Mar 22, 2007 - 9:41 AM

Negative So would he be OK to drive it home? What about me ... Mar 22, 2007 - 9:44 AM

Negative So would he be OK to drive it home? What about me ... Mar 22, 2007 - 9:44 AM

Dr_Tweak QUOTE(Negative @ Mar 22, 2007 - 2:44... Mar 22, 2007 - 10:38 AM

Dr_Tweak QUOTE(Negative @ Mar 22, 2007 - 2:44... Mar 22, 2007 - 10:38 AM

easternpiro1 QUOTE(Dr_Tweak @ Mar 22, 2007 - 10:3... Mar 22, 2007 - 7:52 PM

easternpiro1 QUOTE(Dr_Tweak @ Mar 22, 2007 - 10:3... Mar 22, 2007 - 7:52 PM

Dr_Tweak QUOTE(easternpiro1 @ Mar 23, 2007 - 12... Mar 22, 2007 - 9:43 PM

Dr_Tweak QUOTE(easternpiro1 @ Mar 23, 2007 - 12... Mar 22, 2007 - 9:43 PM

lagos i would follow the same rules toyota tell you when... Mar 22, 2007 - 9:45 AM

lagos i would follow the same rules toyota tell you when... Mar 22, 2007 - 9:45 AM

2slow2nervous thank u than it looks like ill just get my car tow... Mar 22, 2007 - 10:17 AM

2slow2nervous thank u than it looks like ill just get my car tow... Mar 22, 2007 - 10:17 AM

Negative QUOTE(lagos @ Mar 22, 2007 - 2:45 PM... Mar 22, 2007 - 11:28 AM

Negative QUOTE(lagos @ Mar 22, 2007 - 2:45 PM... Mar 22, 2007 - 11:28 AM

2slow2nervous yea dude im really excited just waiting to see the... Mar 22, 2007 - 12:06 PM

2slow2nervous yea dude im really excited just waiting to see the... Mar 22, 2007 - 12:06 PM

gt_driFFter QUOTE(gt_driFFter @ Mar 21, 2007 - 10... Mar 22, 2007 - 12:50 PM

gt_driFFter QUOTE(gt_driFFter @ Mar 21, 2007 - 10... Mar 22, 2007 - 12:50 PM

angrymike lol, you guys are clowning on me about saturns?

t... Mar 23, 2007 - 11:42 PM

angrymike lol, you guys are clowning on me about saturns?

t... Mar 23, 2007 - 11:42 PM

Punisher QUOTE(angrymike @ Mar 24, 2007 - 12... Mar 24, 2007 - 12:35 AM

Punisher QUOTE(angrymike @ Mar 24, 2007 - 12... Mar 24, 2007 - 12:35 AM

Dr_Tweak QUOTE(angrymike @ Mar 24, 2007 - 4:4... Mar 25, 2007 - 12:52 PM

Dr_Tweak QUOTE(angrymike @ Mar 24, 2007 - 4:4... Mar 25, 2007 - 12:52 PM

snapshotgt QUOTE(Dr_Tweak @ Mar 25, 2007 - 12:5... Mar 25, 2007 - 1:03 PM

snapshotgt QUOTE(Dr_Tweak @ Mar 25, 2007 - 12:5... Mar 25, 2007 - 1:03 PM

2slow2nervous how thats sick lol... did u make all that urself? Mar 23, 2007 - 11:47 PM

2slow2nervous how thats sick lol... did u make all that urself? Mar 23, 2007 - 11:47 PM

lagos amazing work. however, if you post that pic next t... Mar 24, 2007 - 12:25 AM

lagos amazing work. however, if you post that pic next t... Mar 24, 2007 - 12:25 AM

angrymike i've been building manifolds for about 4 years... Mar 24, 2007 - 9:31 AM

angrymike i've been building manifolds for about 4 years... Mar 24, 2007 - 9:31 AM

toyotacrazy QUOTE(angrymike @ Mar 24, 2007 - 9:3... Mar 24, 2007 - 12:42 PM

toyotacrazy QUOTE(angrymike @ Mar 24, 2007 - 9:3... Mar 24, 2007 - 12:42 PM

2slow2nervous i just checked that link crazy mike.... thats ****... Mar 24, 2007 - 1:07 PM

2slow2nervous i just checked that link crazy mike.... thats ****... Mar 24, 2007 - 1:07 PM

WH95TE I demand more pics Oh, and I might be moving to S... Mar 24, 2007 - 1:47 PM

WH95TE I demand more pics Oh, and I might be moving to S... Mar 24, 2007 - 1:47 PM

brianforster im on stock hood and bumper and never overheated, ... Mar 24, 2007 - 2:28 PM

brianforster im on stock hood and bumper and never overheated, ... Mar 24, 2007 - 2:28 PM

alltracman78 Whether or not the car has AC will effect it as we... Mar 24, 2007 - 5:24 PM

alltracman78 Whether or not the car has AC will effect it as we... Mar 24, 2007 - 5:24 PM

toyotacrazy I know this is your opinion and you are entitled t... Mar 24, 2007 - 7:36 PM

toyotacrazy I know this is your opinion and you are entitled t... Mar 24, 2007 - 7:36 PM

alltracman78 Your bearings don't "break in"

There... Mar 24, 2007 - 9:26 PM

alltracman78 Your bearings don't "break in"

There... Mar 24, 2007 - 9:26 PM

toyotacrazy QUOTE(alltracman78 @ Mar 24, 2007 - 9... Mar 24, 2007 - 11:22 PM

toyotacrazy QUOTE(alltracman78 @ Mar 24, 2007 - 9... Mar 24, 2007 - 11:22 PM

celicast3sgte no really. they DONT contact, the only time they s... Mar 24, 2007 - 11:27 PM

celicast3sgte no really. they DONT contact, the only time they s... Mar 24, 2007 - 11:27 PM

alltracman78 Exactly.

You can't see it regardless.

But th... Mar 25, 2007 - 11:06 AM

alltracman78 Exactly.

You can't see it regardless.

But th... Mar 25, 2007 - 11:06 AM

brianforster i had to read it twice too but i came to the same ... Mar 25, 2007 - 12:56 PM

brianforster i had to read it twice too but i came to the same ... Mar 25, 2007 - 12:56 PM

angrymike reading comprehension > mike

i wouldn't sa... Mar 25, 2007 - 2:33 PM

angrymike reading comprehension > mike

i wouldn't sa... Mar 25, 2007 - 2:33 PM

2slow2nervous yea that does suck.... Is he gonna build another o... Mar 27, 2007 - 3:02 PM

2slow2nervous yea that does suck.... Is he gonna build another o... Mar 27, 2007 - 3:02 PM

angrymike QUOTE(2slow2nervous @ Mar 27, 2007 - 8... Mar 27, 2007 - 10:07 PM

angrymike QUOTE(2slow2nervous @ Mar 27, 2007 - 8... Mar 27, 2007 - 10:07 PM

2slow2nervous angry mike how do u like working on the celica??? ... Mar 28, 2007 - 10:56 AM

2slow2nervous angry mike how do u like working on the celica??? ... Mar 28, 2007 - 10:56 AM

Negative Uh oh. I smell upgrades. Mar 28, 2007 - 11:19 AM

Negative Uh oh. I smell upgrades. Mar 28, 2007 - 11:19 AM

Punisher man making a custom manifold.. sounds like a night... Mar 28, 2007 - 3:52 PM

Punisher man making a custom manifold.. sounds like a night... Mar 28, 2007 - 3:52 PM

Dr_Tweak You mean like one of these?

http://www.full-race.... Mar 28, 2007 - 4:04 PM

Dr_Tweak You mean like one of these?

http://www.full-race.... Mar 28, 2007 - 4:04 PM

Punisher QUOTE(Dr_Tweak @ Mar 28, 2007 - 5:04... Mar 28, 2007 - 4:18 PM

Punisher QUOTE(Dr_Tweak @ Mar 28, 2007 - 5:04... Mar 28, 2007 - 4:18 PM

playr158 rofl

the manifold is meh...longer runners = ftl t... Mar 28, 2007 - 4:20 PM

playr158 rofl

the manifold is meh...longer runners = ftl t... Mar 28, 2007 - 4:20 PM

Negative Why are you always hatin? The guys trying to help ... Mar 28, 2007 - 4:22 PM

Negative Why are you always hatin? The guys trying to help ... Mar 28, 2007 - 4:22 PM

playr158 its not hating.....its FACT

tubular manifolds don... Mar 28, 2007 - 4:32 PM

playr158 its not hating.....its FACT

tubular manifolds don... Mar 28, 2007 - 4:32 PM

Punisher its not hating... I charge far less to do work for... Mar 28, 2007 - 6:50 PM

Punisher its not hating... I charge far less to do work for... Mar 28, 2007 - 6:50 PM

6th_celi_vert QUOTE(Punisher @ Mar 28, 2007 - 6:50... Mar 28, 2007 - 8:37 PM

6th_celi_vert QUOTE(Punisher @ Mar 28, 2007 - 6:50... Mar 28, 2007 - 8:37 PM

x_itchy_b_x QUOTE(Punisher @ Mar 28, 2007 - 7:50... Mar 28, 2007 - 8:31 PM

x_itchy_b_x QUOTE(Punisher @ Mar 28, 2007 - 7:50... Mar 28, 2007 - 8:31 PM

Dr_Tweak Installing the intercooler...

We cut the en... Mar 28, 2007 - 8:37 PM

Dr_Tweak Installing the intercooler...

We cut the en... Mar 28, 2007 - 8:37 PM

phattyduck QUOTE(Dr_Tweak @ Mar 28, 2007 - 6:37... Mar 30, 2007 - 3:04 AM

phattyduck QUOTE(Dr_Tweak @ Mar 28, 2007 - 6:37... Mar 30, 2007 - 3:04 AM

WannabeGT4 Tweak, about the wiring. Did you extend it to wrap... Mar 28, 2007 - 8:43 PM

WannabeGT4 Tweak, about the wiring. Did you extend it to wrap... Mar 28, 2007 - 8:43 PM

Dr_Tweak QUOTE(WannabeGT4 @ Mar 29, 2007 - 1... Mar 28, 2007 - 8:56 PM

Dr_Tweak QUOTE(WannabeGT4 @ Mar 29, 2007 - 1... Mar 28, 2007 - 8:56 PM

WannabeGT4 QUOTE(Dr_Tweak @ Mar 28, 2007 - 8:56... Mar 28, 2007 - 9:01 PM

WannabeGT4 QUOTE(Dr_Tweak @ Mar 28, 2007 - 8:56... Mar 28, 2007 - 9:01 PM

playr158 QUOTE(6th_celi_vert @ Mar 28, 2007 - 9... Mar 28, 2007 - 9:37 PM

playr158 QUOTE(6th_celi_vert @ Mar 28, 2007 - 9... Mar 28, 2007 - 9:37 PM

Punisher Um.. I said that the saturn manifold is a piece of... Mar 28, 2007 - 9:49 PM

Punisher Um.. I said that the saturn manifold is a piece of... Mar 28, 2007 - 9:49 PM

Dr_Tweak QUOTE(Punisher @ Mar 29, 2007 - 2:49... Mar 29, 2007 - 6:09 AM

Dr_Tweak QUOTE(Punisher @ Mar 29, 2007 - 2:49... Mar 29, 2007 - 6:09 AM

2slow2nervous cars coming along good! i like what im seeing ... Mar 29, 2007 - 9:39 AM

2slow2nervous cars coming along good! i like what im seeing ... Mar 29, 2007 - 9:39 AM

Punisher Swaps.. I also do engine builds/rebuilds, transmis... Mar 29, 2007 - 10:01 PM

Punisher Swaps.. I also do engine builds/rebuilds, transmis... Mar 29, 2007 - 10:01 PM

Batman722 QUOTE(Punisher @ Mar 29, 2007 - 11:0... Mar 29, 2007 - 10:07 PM

Batman722 QUOTE(Punisher @ Mar 29, 2007 - 11:0... Mar 29, 2007 - 10:07 PM

brianforster well tweak kind of called him out on his claim tha... Mar 30, 2007 - 1:49 AM

brianforster well tweak kind of called him out on his claim tha... Mar 30, 2007 - 1:49 AM

playr158 the cross sectional area is the same, unless they ... Mar 30, 2007 - 7:03 AM

playr158 the cross sectional area is the same, unless they ... Mar 30, 2007 - 7:03 AM

Punisher Is the intercooler completely finished as seen in ... Mar 30, 2007 - 7:27 AM

Punisher Is the intercooler completely finished as seen in ... Mar 30, 2007 - 7:27 AM

Dr_Tweak QUOTE(Punisher @ Mar 30, 2007 - 3:01... Mar 30, 2007 - 9:26 AM

Dr_Tweak QUOTE(Punisher @ Mar 30, 2007 - 3:01... Mar 30, 2007 - 9:26 AM

x_itchy_b_x you guys should be board rivals lol! that woul... Mar 30, 2007 - 9:53 AM

x_itchy_b_x you guys should be board rivals lol! that woul... Mar 30, 2007 - 9:53 AM

Dr_Tweak I think not. Mar 30, 2007 - 9:56 AM

Dr_Tweak I think not. Mar 30, 2007 - 9:56 AM

playr158 why can't you compare them?

they are both done... Mar 30, 2007 - 10:04 AM

playr158 why can't you compare them?

they are both done... Mar 30, 2007 - 10:04 AM

snapshotgt Dan, get real - this is not a forum board to discu... Mar 30, 2007 - 10:39 AM

snapshotgt Dan, get real - this is not a forum board to discu... Mar 30, 2007 - 10:39 AM  |

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: February 12th, 2026 - 1:41 PM |