Mar 12, 2008 - 7:57 AM Mar 12, 2008 - 7:57 AM

|

|

Enthusiast      Joined Jan 10, '04 From Shoreline, WA Currently Offline Reputation: 4 (100%) |

Just gathering some opinions and interest on a side project I'm putting together.

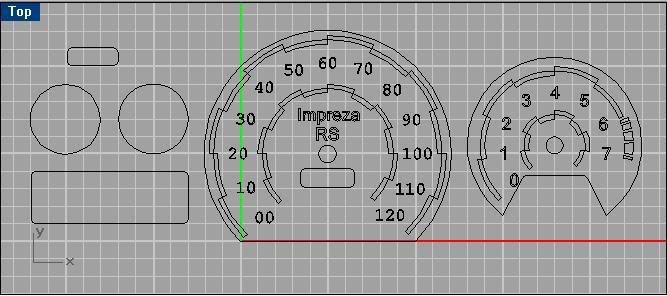

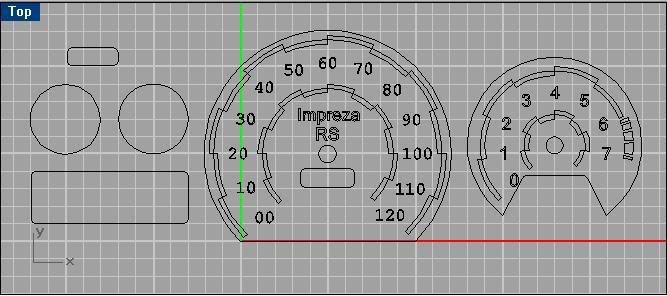

I'm designing a new guage cluster cover for my subaru and celica that will replace the entire OEM cluster face plates and bezle with a single custom designed peace. Its going to be machined from aluminum and fit exactly in place of the original peaces that make up the cluster. this allows for a compleatly new LED backlit design although would not require it. Would anyone be interested in making this a group buy? once I finalize the design I can probably get up to 30 of the celica onces made. I'm compleatly open to anyones design ideas. The cost is compleatly up in the air but the more I have made the less they cost each, and its not my intention to make a profit on this just figured i'ed offer it as a group buy if enough people want in. I dont yet have a model for the celica cluster but below is a screen of the progress on my subaru's design.  anyway, let me know your ideas, designs and if your interested. put in off topic to be safe, as at the moment I'm just collecting ideas and checking intrest. This post has been edited by creis: Mar 12, 2008 - 8:00 AM --------------------  |

|

Replies

Mar 14, 2008 - 6:56 PM Mar 14, 2008 - 6:56 PM

|

|

|

Enthusiast      Joined Jul 7, '03 Currently Offline Reputation: 55 (100%) |

QUOTE(creis @ Mar 12, 2008 - 5:57 AM) [snapback]652577[/snapback] I dont yet have a model for the celica cluster but below is a screen of the progress on my subaru's design.  anyway, let me know your ideas, designs and if your interested. I'm not really sure on the details for the suby what gets cut, where. From the pic above I see lots of square corners. Keep in mind a machine uses bits called endmills similar to a drill bit, but for cutting sideways instead of down like a drill. From a manufacturing stand point, try to avoid sharp inside corners. The smaller the inside radius the smaller tool that has to be used to cut it. Smaller tools have less strength and have to be run at lower feedrates thus taking more time and adding cost to the end product. I am very curious to see the celica one, if you want me to do a machine sim solid render of it let me know I would be happy to do so, and try to help you streamline your design so manufacturing is cheaper for you. -------------------- JDM guy made me do it.

|

Posts in this topic

creis Feeler FS/Group Buy (very early stages) Mar 12, 2008 - 7:57 AM

creis Feeler FS/Group Buy (very early stages) Mar 12, 2008 - 7:57 AM

goferris i would need to see more pics on the design for th... Mar 12, 2008 - 9:41 AM

goferris i would need to see more pics on the design for th... Mar 12, 2008 - 9:41 AM

CelicaST_CALI have u talked to coomer about ur group buy yet???... Mar 12, 2008 - 10:38 AM

CelicaST_CALI have u talked to coomer about ur group buy yet???... Mar 12, 2008 - 10:38 AM

96bluevert Wasn't Griffgirl also working on some custom g... Mar 12, 2008 - 12:07 PM

96bluevert Wasn't Griffgirl also working on some custom g... Mar 12, 2008 - 12:07 PM

presure2 all group buys need to be approved by chris at thi... Mar 12, 2008 - 3:49 PM

presure2 all group buys need to be approved by chris at thi... Mar 12, 2008 - 3:49 PM

j0e_p3t i'd be interested. depending on cost and how i... Mar 13, 2008 - 12:13 AM

j0e_p3t i'd be interested. depending on cost and how i... Mar 13, 2008 - 12:13 AM

creis QUOTEall group buys need to be approved by chris a... Mar 13, 2008 - 1:19 AM

creis QUOTEall group buys need to be approved by chris a... Mar 13, 2008 - 1:19 AM

presure2 QUOTE(creis @ Mar 13, 2008 - 2:19 AM... Mar 14, 2008 - 6:38 PM

presure2 QUOTE(creis @ Mar 13, 2008 - 2:19 AM... Mar 14, 2008 - 6:38 PM

creis ^ Thanks, will deff contact you on it. The initial... Mar 17, 2008 - 3:39 PM

creis ^ Thanks, will deff contact you on it. The initial... Mar 17, 2008 - 3:39 PM

GriffGirl ^ contact me if you're interested in working t... Mar 17, 2008 - 3:53 PM

GriffGirl ^ contact me if you're interested in working t... Mar 17, 2008 - 3:53 PM

creis ^ interested but I wana get things figured out fir... Mar 26, 2008 - 3:50 AM

creis ^ interested but I wana get things figured out fir... Mar 26, 2008 - 3:50 AM

GriffGirl Have you thought about doing it as an overlay of s... Mar 27, 2008 - 7:18 PM

GriffGirl Have you thought about doing it as an overlay of s... Mar 27, 2008 - 7:18 PM

creis I though about making it an easy slide on kinda th... Mar 28, 2008 - 1:39 AM

creis I though about making it an easy slide on kinda th... Mar 28, 2008 - 1:39 AM

lubu Sounds good.Im very interested and in for a set. Mar 28, 2008 - 9:09 AM

lubu Sounds good.Im very interested and in for a set. Mar 28, 2008 - 9:09 AM

jazzcornet any chance on making one for an sw20? i'd be i... Mar 28, 2008 - 6:58 PM

jazzcornet any chance on making one for an sw20? i'd be i... Mar 28, 2008 - 6:58 PM  |

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: January 16th, 2026 - 6:53 AM |