Jan 24, 2009 - 8:56 PM Jan 24, 2009 - 8:56 PM

|

|

Enthusiast     Joined Aug 11, '08 From London Currently Offline Reputation: 7 (100%) |

Hi guys and dolls.

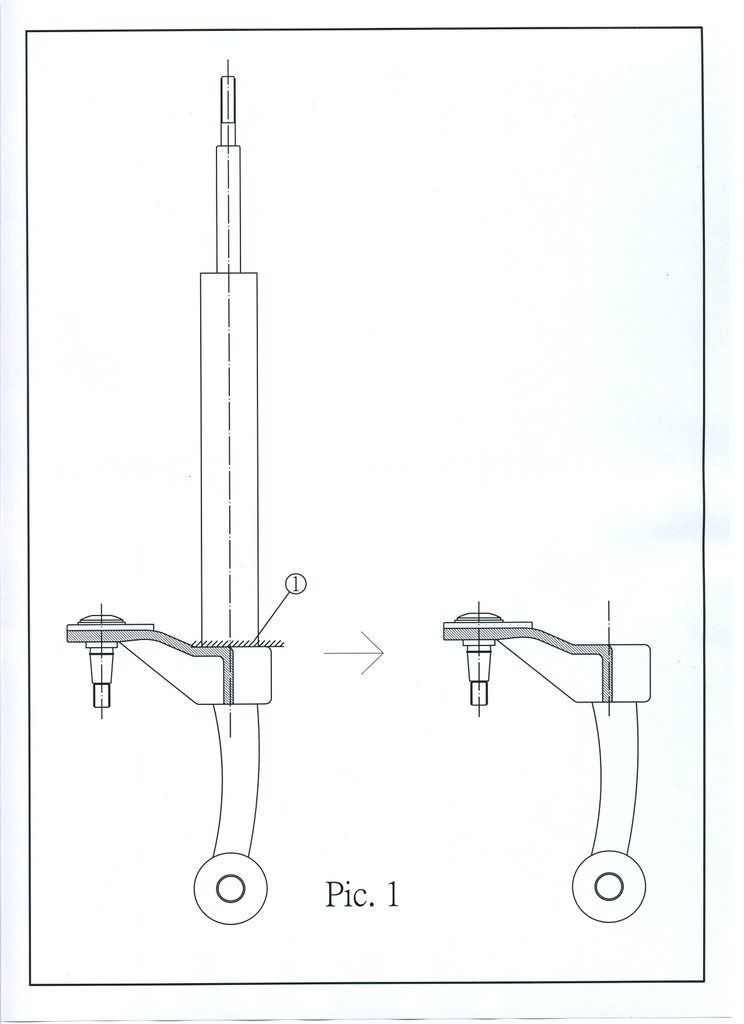

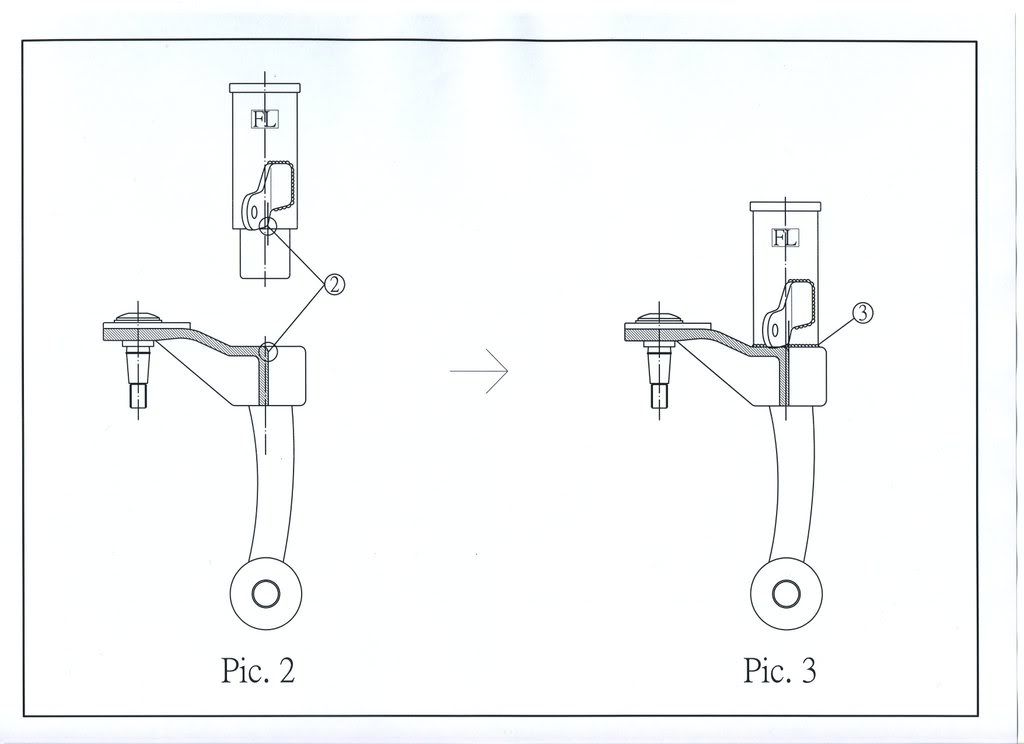

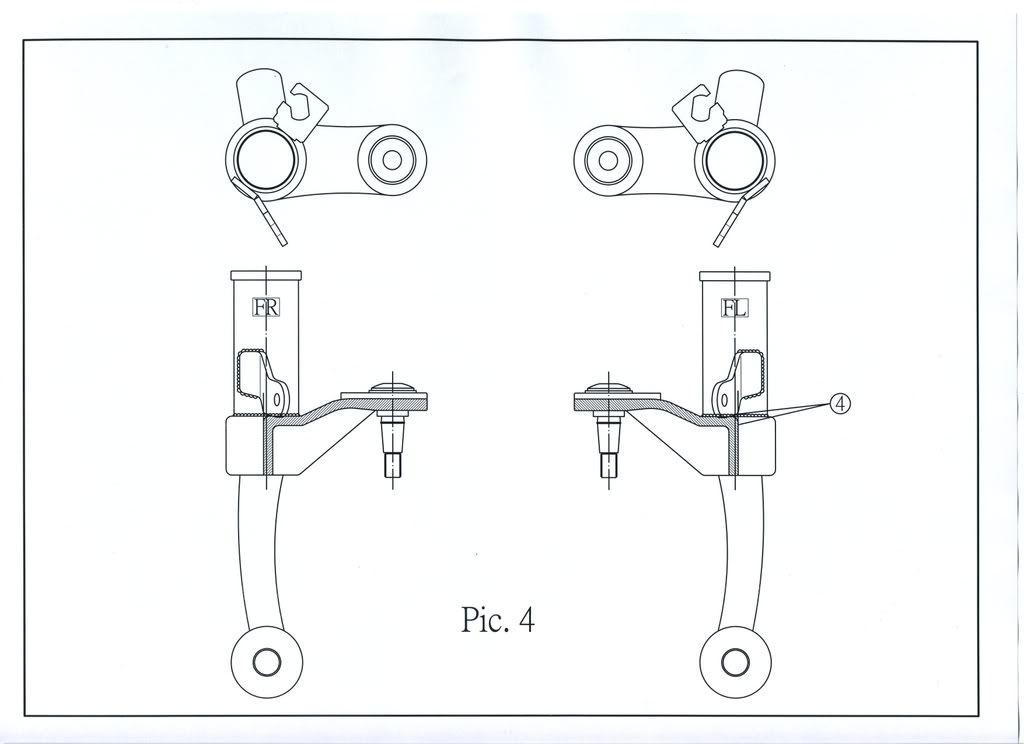

BC have recently developed some coilovers for the ST205. http://cgi.ebay.co.uk/BC-Adjustable-Coilov...A1%7C240%3A1318 Normally eveyrone in the UK only buy Tein an TRD coilovers and tent to avoid every other brands when it comes to coilover. Recently in GBP isnt doing so well and Tein has also anounced a huge price increase hence putting me into the "definately cant afford" status. Well the new BC coilovers have adopted the idea of using the origional housing of the stock Super strut shocks and changing the inserts like the D2, k-sport and G4's. In a nutshell it's a crap design but BC's inserts are different as they require you to cut the stock shocks down and allowing you to use the full length of the coilover shocks. Here are some pictures I've been sent and I've been convinced to be the first to try a set in the UK.       Untill now I've not heard of BC before in the UK but after doing some research, I've found that they're pretty good. So what's everyones opinion with BC around the world on other cars? Has anyone experienced using them before? Ray |

|

Replies

Feb 4, 2009 - 12:20 PM Feb 4, 2009 - 12:20 PM

|

|

Enthusiast     Joined Aug 11, '08 From London Currently Offline Reputation: 7 (100%) |

Last night I started working on cutting the stock leg Taras had donated to me for this project.

The aim was to cut the leg down to just the lower section of the superstrut. The tools I had to do this job with was: Angle grinder with grinding and cutting blades hacksaw File Vice clamp And for safety: Goggles and gloves I first started by securing the legs in a vice clamp and then began cutting away with the angle grinder. The first problem was clamping it securely. Because the legs had other bits like the brake hose holder sticking out, I was limited to how to clamp it down and also my angle grinder couln't cut all the way round.  I managed to cut about 2 thirds the way round and about less then a cm away from the bottom. Using a hacksaw I manually sawed the rest off. These where the bits that was not needed:  and I was left with this:  Next thing was to change the blades to a grindig blade and stert to take the excess bits down to the bottom and evening it out.  This took a long time because even though I cut the legs down with less then 1cm left, that was still a lot to grind away. Also towards the end I had to stop, check and grind again trying to make sure that the surface was evenly flat. This really tested my patience. After when I thought I had finished with the angle grinder, I used a course flat file and started to skim the surface in all directions to ensure the surface was flat.  The end result was a mnice, smooth and flat surface.  Notice how I left about a 1mm edge there. In the instructions, it dodnt say how far you're suppose to take it down to. I decided to not take it all the way down because I didn't want to risk making a mess with the angle grinder and to give a bit of a lip for when i tap weld it. As long as both legs are evenly the same there shouldnt be a problem. So here they are after cutting:  And give them a good wash:  Then finally back home for a test fit:  Now they're looking more like a super strut coil over NOTE that I didnt insert them fully just in case I had to take them off again. I was really impress how nicely they fitted into the legs. It was air tight with no play what so ever and I had to tap it a bit to get it that far in. At first I was a bit worried abut it not fitting here because if it was too big, I'd have to drill the leg a bit and too small would mean play and that will ruin everything. BC had made these insert to fit perfectly and I'm very pleased with it so well done. Next is to order new bushes as the ones in the legs now are leaking and there's none in stock so I should get them by next week. Then I'll need to take it to my friends workshop for the leaking bushes to be pressed out and replaced and finally insert the coilovers in and weld them down. Overvies so far: Everything is coming to plan and there has been no surprises. The scariest bit is over and I'm a bit relieved. Cutting the legs took just over 2 hours with the tools I had. I do want to point out that this was not a job for the faint hearted. I was covered in metal shavings and made a bit of a mess at the garage. Where as most DIY mechanics are confident with bolt on and bolt off upgrades, this definately requires some engineering confidence and a lot of patiences. I did enjoy doing this but I can also imagine that a lot of people would be reluctant to give it a try. However, this only applys to the ST205 superstrut. ST185, and ST202,3,4 BC coil overs wouldn't have to face this problem but I'm sure most ST205 owners wouldnt mind this becasue we are faffers and saving almost a grand with these coilovers if they work. |

Posts in this topic

yellowchinaman BC coilovers for the GT4 Jan 24, 2009 - 8:56 PM

yellowchinaman BC coilovers for the GT4 Jan 24, 2009 - 8:56 PM

celica3000 last week search coilovers for my celica and find ... Jan 25, 2009 - 6:32 AM

celica3000 last week search coilovers for my celica and find ... Jan 25, 2009 - 6:32 AM

yellowchinaman That's not the same one Celica3000.

This one i... Jan 25, 2009 - 9:01 AM

yellowchinaman That's not the same one Celica3000.

This one i... Jan 25, 2009 - 9:01 AM

celica3000 yes, i see it is st 205

i share the information... Jan 25, 2009 - 9:27 AM

celica3000 yes, i see it is st 205

i share the information... Jan 25, 2009 - 9:27 AM

VinT Ray, very usefull information. thanks.

Will you bu... Jan 29, 2009 - 1:22 PM

VinT Ray, very usefull information. thanks.

Will you bu... Jan 29, 2009 - 1:22 PM

yellowchinaman yes I did. Arrived this morning and I'm the fi... Jan 29, 2009 - 8:52 PM

yellowchinaman yes I did. Arrived this morning and I'm the fi... Jan 29, 2009 - 8:52 PM

NGHTKD Im going to get these for my Celica...

prefer them... Jan 30, 2009 - 4:38 AM

NGHTKD Im going to get these for my Celica...

prefer them... Jan 30, 2009 - 4:38 AM

yellowchinaman Ok so I've had a good inspection of the BC coi... Jan 31, 2009 - 7:32 AM

yellowchinaman Ok so I've had a good inspection of the BC coi... Jan 31, 2009 - 7:32 AM

trdproven Megan coilovers are indeed getting cheaper. Got m... Jan 31, 2009 - 8:13 AM

trdproven Megan coilovers are indeed getting cheaper. Got m... Jan 31, 2009 - 8:13 AM

yellowchinaman yeah unfortunately for us here in the uk the GBP i... Jan 31, 2009 - 9:08 AM

yellowchinaman yeah unfortunately for us here in the uk the GBP i... Jan 31, 2009 - 9:08 AM

chacha please and thank you for keep us updated on this b... Jan 31, 2009 - 6:04 PM

chacha please and thank you for keep us updated on this b... Jan 31, 2009 - 6:04 PM

celica3000 good review

send email for bc uk ask shipping to ... Feb 1, 2009 - 7:00 AM

celica3000 good review

send email for bc uk ask shipping to ... Feb 1, 2009 - 7:00 AM

azian_advanced i'm still stumped as to how these are installe... Feb 1, 2009 - 10:07 AM

azian_advanced i'm still stumped as to how these are installe... Feb 1, 2009 - 10:07 AM

Culpable04 I think that has to be done only for the super str... Feb 1, 2009 - 11:03 AM

Culpable04 I think that has to be done only for the super str... Feb 1, 2009 - 11:03 AM

yellowchinaman QUOTE (azian_advanced @ Feb 1, 2009 - 10... Feb 1, 2009 - 11:12 PM

yellowchinaman QUOTE (azian_advanced @ Feb 1, 2009 - 10... Feb 1, 2009 - 11:12 PM

BonzaiCelica QUOTE (yellowchinaman @ Feb 2, 2009 - 12... Sep 6, 2012 - 9:24 PM

BonzaiCelica QUOTE (yellowchinaman @ Feb 2, 2009 - 12... Sep 6, 2012 - 9:24 PM

azian_advanced i understand that part, i bought a set of blown su... Feb 1, 2009 - 11:36 PM

azian_advanced i understand that part, i bought a set of blown su... Feb 1, 2009 - 11:36 PM

yellowchinaman not alot. I've not taken the inserts out perso... Feb 2, 2009 - 7:07 PM

yellowchinaman not alot. I've not taken the inserts out perso... Feb 2, 2009 - 7:07 PM

whatthe Hey im doing some rearch on lowering my car, and B... Feb 3, 2009 - 11:16 AM

whatthe Hey im doing some rearch on lowering my car, and B... Feb 3, 2009 - 11:16 AM

yellowchinaman how long will they last is like asking how long is... Feb 3, 2009 - 11:38 AM

yellowchinaman how long will they last is like asking how long is... Feb 3, 2009 - 11:38 AM

whatthe ^yes they make it for the st202/3/4. Ive got my ey... Feb 3, 2009 - 11:51 AM

whatthe ^yes they make it for the st202/3/4. Ive got my ey... Feb 3, 2009 - 11:51 AM

yellowchinaman save up because in the end I'm organising a gr... Feb 3, 2009 - 8:55 PM

yellowchinaman save up because in the end I'm organising a gr... Feb 3, 2009 - 8:55 PM

whatthe ^ that sounds great man, i was going to organise s... Feb 3, 2009 - 9:00 PM

whatthe ^ that sounds great man, i was going to organise s... Feb 3, 2009 - 9:00 PM

VinT Looking good. But I have one question..

Are there ... Feb 5, 2009 - 7:58 AM

VinT Looking good. But I have one question..

Are there ... Feb 5, 2009 - 7:58 AM

yellowchinaman nope. You just press them all the way in and then ... Feb 5, 2009 - 11:22 AM

yellowchinaman nope. You just press them all the way in and then ... Feb 5, 2009 - 11:22 AM

VinT QUOTE (yellowchinaman @ Feb 5, 2009 - 12... Feb 12, 2009 - 6:29 PM

VinT QUOTE (yellowchinaman @ Feb 5, 2009 - 12... Feb 12, 2009 - 6:29 PM

yellowchinaman ok another small update.

I didnt do much last week... Feb 19, 2009 - 11:51 AM

yellowchinaman ok another small update.

I didnt do much last week... Feb 19, 2009 - 11:51 AM

mikaelhoglund Hello!

I have a D2 coiloverkit and it works fi... Feb 27, 2009 - 10:08 AM

mikaelhoglund Hello!

I have a D2 coiloverkit and it works fi... Feb 27, 2009 - 10:08 AM

yellowchinaman QUOTE (mikaelhoglund @ Feb 27, 2009 - 10... Mar 3, 2009 - 9:57 AM

yellowchinaman QUOTE (mikaelhoglund @ Feb 27, 2009 - 10... Mar 3, 2009 - 9:57 AM

SveNRG For those of you eagerly awaiting more info, here... Mar 27, 2009 - 3:09 AM

SveNRG For those of you eagerly awaiting more info, here... Mar 27, 2009 - 3:09 AM

yellowchinaman Well it's been a long wait but its finally all... Apr 8, 2009 - 4:37 PM

yellowchinaman Well it's been a long wait but its finally all... Apr 8, 2009 - 4:37 PM

AnaXyd Great writeup! Do you suggest BC instead of Me... Jun 11, 2009 - 2:33 PM

AnaXyd Great writeup! Do you suggest BC instead of Me... Jun 11, 2009 - 2:33 PM

SveNRG Thank you for this great write-up! I'm ser... Jul 6, 2009 - 2:32 AM

SveNRG Thank you for this great write-up! I'm ser... Jul 6, 2009 - 2:32 AM

95CelicaST BC coilovers are highly regarded in the Subaru com... Jul 22, 2009 - 12:08 PM

95CelicaST BC coilovers are highly regarded in the Subaru com... Jul 22, 2009 - 12:08 PM

3WayStunna Not to sound ignorant, or silly, but will all sets... Jul 23, 2009 - 4:03 AM

3WayStunna Not to sound ignorant, or silly, but will all sets... Jul 23, 2009 - 4:03 AM

yellowchinaman QUOTE (3WayStunna @ Jul 23, 2009 - 5... Jul 23, 2009 - 7:42 AM

yellowchinaman QUOTE (3WayStunna @ Jul 23, 2009 - 5... Jul 23, 2009 - 7:42 AM

3WayStunna well thank you much Chinaman. Speaking for myself,... Jul 28, 2009 - 5:38 AM

3WayStunna well thank you much Chinaman. Speaking for myself,... Jul 28, 2009 - 5:38 AM

yellowchinaman QUOTE (3WayStunna @ Jul 28, 2009 - 6... Jul 28, 2009 - 8:55 AM

yellowchinaman QUOTE (3WayStunna @ Jul 28, 2009 - 6... Jul 28, 2009 - 8:55 AM

Wolf_tm Hi Ray !!!

As I fitted them too, what... Oct 3, 2009 - 6:30 AM

Wolf_tm Hi Ray !!!

As I fitted them too, what... Oct 3, 2009 - 6:30 AM

delusionz QUOTE (Wolf_tm @ Oct 3, 2009 - 11:30... Jul 8, 2012 - 1:57 PM

delusionz QUOTE (Wolf_tm @ Oct 3, 2009 - 11:30... Jul 8, 2012 - 1:57 PM

yellowchinaman Hi Wolf. I dont have that problem. I have much mor... Oct 3, 2009 - 12:44 PM

yellowchinaman Hi Wolf. I dont have that problem. I have much mor... Oct 3, 2009 - 12:44 PM

Wolf_tm QUOTE (yellowchinaman @ Oct 3, 2009 - 7... Oct 4, 2009 - 2:46 AM

Wolf_tm QUOTE (yellowchinaman @ Oct 3, 2009 - 7... Oct 4, 2009 - 2:46 AM

jackett How do you find these coilovers compared to Tein S... Oct 4, 2009 - 4:51 PM

jackett How do you find these coilovers compared to Tein S... Oct 4, 2009 - 4:51 PM

Wolf_tm QUOTE (jackett @ Oct 4, 2009 - 11:51... Oct 5, 2009 - 3:34 AM

Wolf_tm QUOTE (jackett @ Oct 4, 2009 - 11:51... Oct 5, 2009 - 3:34 AM

Wolf_tm Received a mail from BC racing:

for them 4mm clear... Oct 5, 2009 - 8:50 AM

Wolf_tm Received a mail from BC racing:

for them 4mm clear... Oct 5, 2009 - 8:50 AM

Mercer What is the ride height adjustablity like, i see u... Jan 1, 2010 - 7:12 PM

Mercer What is the ride height adjustablity like, i see u... Jan 1, 2010 - 7:12 PM

VinT yellowchinaman, please post something about riding... Feb 9, 2010 - 5:41 AM

VinT yellowchinaman, please post something about riding... Feb 9, 2010 - 5:41 AM

nics isnt it that megan racing coilovers are rebranded ... Feb 9, 2010 - 4:50 PM

nics isnt it that megan racing coilovers are rebranded ... Feb 9, 2010 - 4:50 PM

Penkka Yeah its Bor-Chuann, and they have made coilovers ... Jun 10, 2010 - 10:01 AM

Penkka Yeah its Bor-Chuann, and they have made coilovers ... Jun 10, 2010 - 10:01 AM

GT4 Hello guys..This Bc coilcovers can fit on toyota c... Oct 5, 2011 - 4:59 AM

GT4 Hello guys..This Bc coilcovers can fit on toyota c... Oct 5, 2011 - 4:59 AM

BonzaiCelica QUOTE (GT4 @ Oct 5, 2011 - 4:59 AM) ... Oct 5, 2011 - 5:42 PM

BonzaiCelica QUOTE (GT4 @ Oct 5, 2011 - 4:59 AM) ... Oct 5, 2011 - 5:42 PM

malpaso QUOTE (GT4 @ Oct 5, 2011 - 11:59 AM)... Oct 6, 2011 - 3:02 AM

malpaso QUOTE (GT4 @ Oct 5, 2011 - 11:59 AM)... Oct 6, 2011 - 3:02 AM

zeus83 digging this old thread....

thanks Ray for the gr... May 9, 2012 - 1:00 AM

zeus83 digging this old thread....

thanks Ray for the gr... May 9, 2012 - 1:00 AM

Neon90424 im loving my Bc coilovers, awesome in everyway... May 9, 2012 - 4:03 AM

Neon90424 im loving my Bc coilovers, awesome in everyway... May 9, 2012 - 4:03 AM

yellowchinaman wow. Didnt think this thread was still going on.

O... May 9, 2012 - 9:39 AM

yellowchinaman wow. Didnt think this thread was still going on.

O... May 9, 2012 - 9:39 AM

zeus83 glad to hear your positive feedback guys!

so ... May 11, 2012 - 2:57 AM

zeus83 glad to hear your positive feedback guys!

so ... May 11, 2012 - 2:57 AM

yellowchinaman I had a friend use Mig weld on them and it was onl... May 15, 2012 - 12:34 PM

yellowchinaman I had a friend use Mig weld on them and it was onl... May 15, 2012 - 12:34 PM

zeus83 cool!

but mind me asking, why not weld all r... May 30, 2012 - 3:45 AM

zeus83 cool!

but mind me asking, why not weld all r... May 30, 2012 - 3:45 AM

zeus83 ok...lets start!

First of all thanks to Ray a... Jul 3, 2012 - 8:20 AM

zeus83 ok...lets start!

First of all thanks to Ray a... Jul 3, 2012 - 8:20 AM

BonzaiCelica yes 2 year revival. okay since this is alongside w... Sep 10, 2014 - 3:22 AM

BonzaiCelica yes 2 year revival. okay since this is alongside w... Sep 10, 2014 - 3:22 AM

qatar11 This is timely..... I recently got a set of BCs fo... Sep 11, 2014 - 8:19 AM

qatar11 This is timely..... I recently got a set of BCs fo... Sep 11, 2014 - 8:19 AM

carina3sge Hi there,

I have a carina GTI that I want to fit ... Aug 17, 2015 - 1:56 PM

carina3sge Hi there,

I have a carina GTI that I want to fit ... Aug 17, 2015 - 1:56 PM

njccmd2002 sorry, but we dont have carinas in the usa. we wo... Sep 9, 2015 - 6:42 AM

njccmd2002 sorry, but we dont have carinas in the usa. we wo... Sep 9, 2015 - 6:42 AM

marinos Great write up, thanks for the info.

I m wondering... Oct 6, 2015 - 11:02 AM

marinos Great write up, thanks for the info.

I m wondering... Oct 6, 2015 - 11:02 AM  |

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: January 16th, 2026 - 11:22 AM |