Sep 30, 2012 - 8:35 PM Sep 30, 2012 - 8:35 PM

|

|

|

Enthusiast  Joined Sep 9, '12 From 13114 Currently Offline Reputation: 0 (0%) |

Well, here is my first Step by Step post.

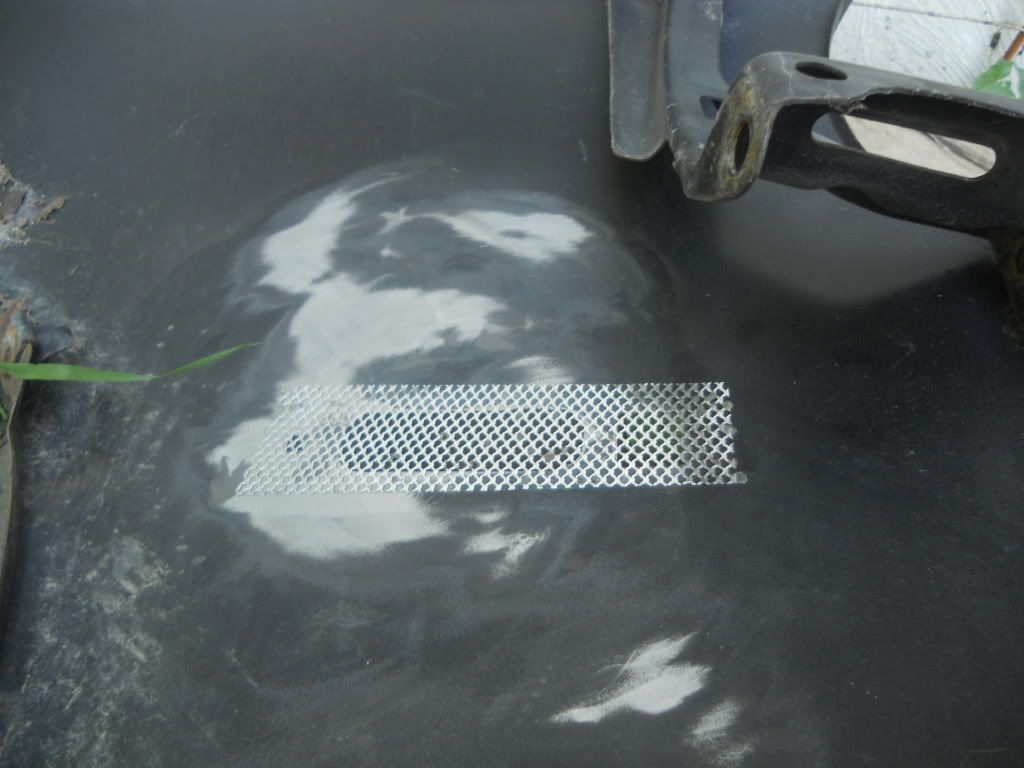

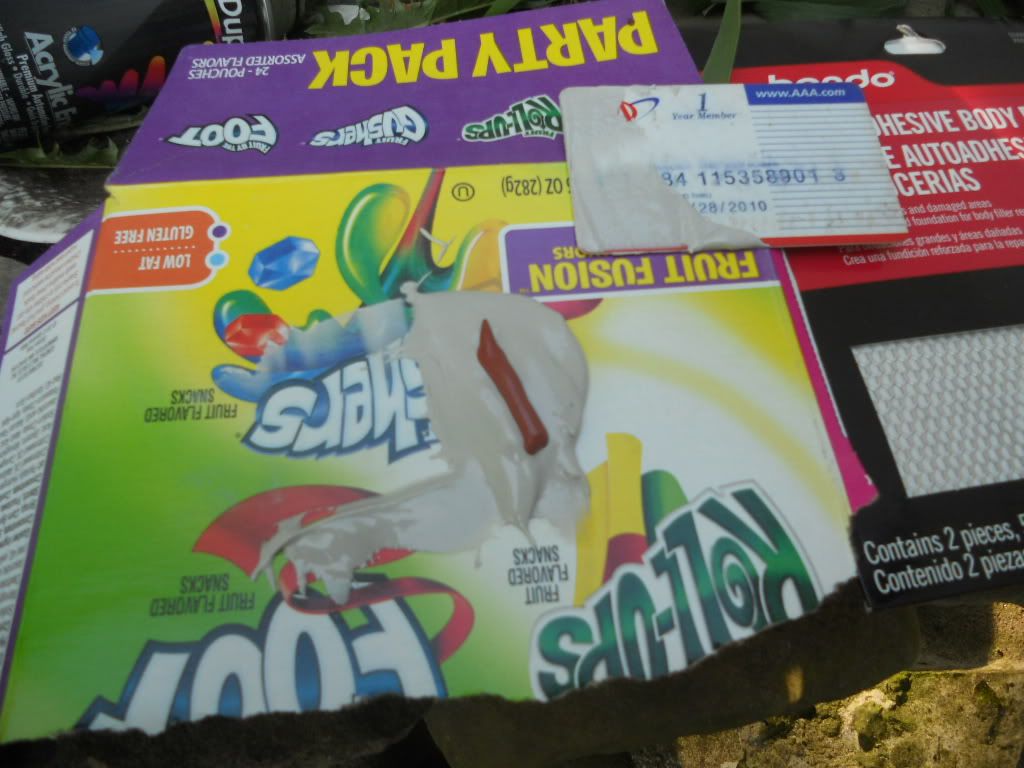

I'm in the process of shaving my front fenders side markers. I do not recommend if your state requires them. So here is the rift: Necessary Materials: Dual action Sander(or Hand, just takes at least double the time!!) Sand paper, 40, 80, and 320 grit Bondo body filler Fiberglass resin Fiberglass mat Bondo Body patch scissors GLOVES!! Breathing MASK First off, i removed my fenders, Step 1; remove tire. Step 2; Remove wheel well shroud, i think about 10-12 screws. Step 3; Remove the 3, 10mm bolts from the fender to the front bumper, then the one bolt from the firewall, on the inside of the fender, then the 2 bolts on the bottom corner under the door jam, and then the bolts inside the door jam(door open to access them), and finally the top 3 bolts under the hood, on the side well. Step 4; After partially removing the fenders, there is a bracket attached below the low beam lights. 2, 10mm bolts. I was able to access them without pulling the lights or bumper, so if you want to do that route, do it. Step 5; Picture time! here is my drivers side fender before prep:  First off, i removed the plastic piece that holds the screw in, used pliers, pinching in the side tabs, while lightly tapping with a hammer. Next, using the dual action sander, and 40 grit paper i cleaned around the outside, down through the clear coat, base-coat, and primer. Right down to metal. like this:  I then cleaned the inside of the fender, and cut a Body patch to size, and applied to the inside:  this is the outside:  The body patches i used, there are 2 per pack:  I then used gloves, bondo body filler, piece of cardboard and an old card as the applicator(call me cheap):  I mixed about a golf ball size of filler with about a 2 inch line of hardener, and mixed and kneaded in(don't knock the old AAA card, LOL):  Then using the card as an applicator, i lightly applied into the patch, and around the old hole, carefully making sure to overlap the onto the fender and blending around it. like this:  After allowing the Bondo to harden, i then used the sander with 80 grit to sand down and around the old marker. Making sure not to go to far down. Basically i made it level with the fenders:  Next step is the fiber glassing, materials used: Bondo fiberglass resin Fiberglass mat Cheap paint brush Old plastic dish scissors *MOST IMPORTANT* Gloves( for reasons i will explain later) Breathing mask(same as above) Here:  I first cut two strips of fiberglass mat:  I then mixed about 3-5 ounces of resin to about 15-20 DROPS of hardener. After thoroughly mixing, you've got about 10 minutes of work time. I first laid down a layer of resin, and then applied a strip of fiberglass mat. I then brushed it out, making sure to get all the bubbles out. and then applied another layer of resin. Now its optional to apply both strips. I did it to better insure that the hole would better blend into the fender. here is the end result of the fiberglass:  SO what i was going to say about the gloves and mask. First off, the gloves are a must!! If you do not, then don't plan on scratching your ass afterwards, or your wont stop scratching for about a week, maybe two. Trust me on that. and it doesn't even have to be your butt. Fiberglass is some nasty stuff to get on you. especially the resin and mat mixture. The mask, well its some strong smelling stuff, and without the mask, you better have some crazy ventilation. So that's it so far. my next steps will be on sanding down, blending it in, priming, more blending and finally paint. so more to follow! -------------------- "I won't be wronged, I won't be insulted, and I won't be laid a hand on. I don't do these things to other people, and I require the same from them." John Wayne

“A little knowledge is a dangerous thing. So is a lot.” -Einstein- "Taking Life One Day at a time, and Never Looking Back" -Herb- DUKE HAS SPOKEN |

|

Replies

Oct 2, 2012 - 1:41 PM Oct 2, 2012 - 1:41 PM

|

|

|

Enthusiast  Joined Sep 9, '12 From 13114 Currently Offline Reputation: 0 (0%) |

well i originally used just filler, bondo body patches, and spot/hole glaze(red putty). it turned out alright on the other fender, but the issue i had was that you can still see outlines of original holes. so unless i can get it better blended, then i will be taking it all down and do it the fiberglass way.

heres some pics of that outcome:  This is fender primed with just the bondo and patch. its difficult to see, but the bondo lifted and cracked, and also you can make out the original lines  this is a close up of the spot where the marker used to be. its difficult to see, but the line that lines in the pic is the outside cut of hole, and you can also see the pitting that wouldn't fill up. Now in comparison to this way and fiber-glassing, i find the fiberglass to be more efficient and much more easier to complete. A lot of people get kinda scared to do it, but honestly, it was easier than what other people have told me. But that's just my experience, and maybe some may have a better and easier experience, and more power to you! And hell yes to the fruit roll-ups, gushers, and fruit by the foot. I forgot to add a step now that i remember-energy replenishment or i like my sugar buzz to keep the work going!!! lmao... Now onto the next step. just one. but i found to be the most difficult, just getting the blending right. Materials used: Suggest gloves because of the obvious Mask Definetly Dual action Hand Sander 40 grit sand paper 80 grit sand paper time muscles. So getting back onto the show, the next step that i completed was the sanding down and blending of the fiberglass patch. First off, the main problem I encountered was dust getting every where. that's why after about 5 minutes of sanding i busted out my full face respirator. I was coughing and eyes were burning. Nuff' said. lol. and gloves. But back on track, i started by dampening an old rag, and did a wipe down of the area, and went about 3 inches past the fiberglass. I then started with the 40 grit paper and sander. I found using a circular motion while applying pressure, worked the best. Because the 40 grit is extremely course, i didn't want to cause warping in the sheet metal, hence forth the circular motion. plus it helped with the blending and evening out. this is the end result:  its a bit dusty, cause i haven't wiped down yet. But after blending it right down to metal, i followed by using 80 grit to smooth it a little bit flatter. So this is it so far, and next to follow will be the priming, filling, priming again, sanding, painting and clear coat. oh and more sanding. So like i said, time. you don't want to rush these things. More to follow soon! -------------------- "I won't be wronged, I won't be insulted, and I won't be laid a hand on. I don't do these things to other people, and I require the same from them." John Wayne

“A little knowledge is a dangerous thing. So is a lot.” -Einstein- "Taking Life One Day at a time, and Never Looking Back" -Herb- DUKE HAS SPOKEN |

Posts in this topic

Duke Shaving side markers. Sep 30, 2012 - 8:35 PM

Duke Shaving side markers. Sep 30, 2012 - 8:35 PM

azian_advanced sticky! Sep 30, 2012 - 11:32 PM

azian_advanced sticky! Sep 30, 2012 - 11:32 PM

Box FRUIT ROLL-UPS, FRUIT BY THE FOOT, AND GUSHERS... Oct 1, 2012 - 12:24 AM

Box FRUIT ROLL-UPS, FRUIT BY THE FOOT, AND GUSHERS... Oct 1, 2012 - 12:24 AM

mkernz22 I did mine the exact same way as you did yours, bu... Oct 1, 2012 - 3:40 PM

mkernz22 I did mine the exact same way as you did yours, bu... Oct 1, 2012 - 3:40 PM

bigb1970 I'm lucky i don't have them Oct 1, 2012 - 4:28 PM

bigb1970 I'm lucky i don't have them Oct 1, 2012 - 4:28 PM

Syaoran I really want to have mine removed. Oct 1, 2012 - 6:31 PM

Syaoran I really want to have mine removed. Oct 1, 2012 - 6:31 PM

celica-supra About to do similar with my anntena, looking good ... Oct 2, 2012 - 2:49 PM

celica-supra About to do similar with my anntena, looking good ... Oct 2, 2012 - 2:49 PM

Duke thanks celica-supra! good luck, and i know tha... Oct 2, 2012 - 3:27 PM

Duke thanks celica-supra! good luck, and i know tha... Oct 2, 2012 - 3:27 PM

Edser When will we see it on the car? Oct 2, 2012 - 5:07 PM

Edser When will we see it on the car? Oct 2, 2012 - 5:07 PM

Duke well if alls goes well im hoping to have the front... Oct 2, 2012 - 10:07 PM

Duke well if alls goes well im hoping to have the front... Oct 2, 2012 - 10:07 PM

Box When I respray my car I must do this. I never und... Oct 2, 2012 - 10:12 PM

Box When I respray my car I must do this. I never und... Oct 2, 2012 - 10:12 PM

Duke QUOTE (Box @ Oct 2, 2012 - 11:12 PM)... Oct 2, 2012 - 10:36 PM

Duke QUOTE (Box @ Oct 2, 2012 - 11:12 PM)... Oct 2, 2012 - 10:36 PM

Box Might be a wasp nest, since I've acquired it. ... Oct 2, 2012 - 11:13 PM

Box Might be a wasp nest, since I've acquired it. ... Oct 2, 2012 - 11:13 PM

Duke haha. I hope so. For your sake. Lmao.... Oct 2, 2012 - 11:17 PM

Duke haha. I hope so. For your sake. Lmao.... Oct 2, 2012 - 11:17 PM

Box So far it's been spotless with none of the usu... Oct 2, 2012 - 11:30 PM

Box So far it's been spotless with none of the usu... Oct 2, 2012 - 11:30 PM

trdproven or you can use sheet metal instead of the mesh. Oct 3, 2012 - 9:48 PM

trdproven or you can use sheet metal instead of the mesh. Oct 3, 2012 - 9:48 PM

Duke yea that was my first idea, but i dont have the ne... Oct 3, 2012 - 10:30 PM

Duke yea that was my first idea, but i dont have the ne... Oct 3, 2012 - 10:30 PM

trdproven gotcha, good write-up though. Oct 10, 2012 - 7:28 PM

trdproven gotcha, good write-up though. Oct 10, 2012 - 7:28 PM  |

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: January 19th, 2026 - 1:31 PM |