Jul 12, 2005 - 7:13 PM Jul 12, 2005 - 7:13 PM

|

|

Enthusiast    Joined Feb 22, '04 From USA Currently Offline Reputation: 3 (100%) |

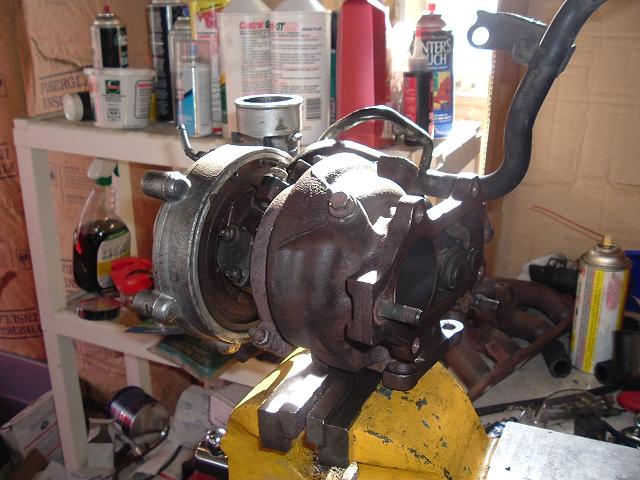

i see that lagos has done this i would like his help or anyone elses in structions on how to do this. what size pipping is there a place where i can buy all the piping the way i need it right now instead of getting it bent?? intercooler?? what do i get that will i need one for both intakes?? http://www.6gc.net/photo.php?file=/images/...hotos/60_14.jpg the 2 pipes here sorry Lagos i stole ur picture just for reference i hope u dont mind. how easy is this to do estimated time? is it easier than a air intake?? thanks would be grateful for the help. and also estimate cost??

|

|

Replies

(1 - 8)

Jul 12, 2005 - 7:34 PM Jul 12, 2005 - 7:34 PM

|

|

|

Enthusiast      Joined Aug 31, '02 From Philadelphia, PA Currently Offline Reputation: 8 (100%) |

what motor do you plan to install this on ? are you doing a swap ?

-------------------- 15PSI - 30MPG - Megasquirt Tuned

|

Jul 12, 2005 - 8:51 PM Jul 12, 2005 - 8:51 PM

|

|

Enthusiast    Joined Feb 22, '04 From USA Currently Offline Reputation: 3 (100%) |

it is a 5th gen that already had a 3sgte swap done has the intercooler on the top. has bout 200 hp.

|

Jul 12, 2005 - 10:10 PM Jul 12, 2005 - 10:10 PM

|

|

|

Enthusiast      Joined Aug 31, '02 From Philadelphia, PA Currently Offline Reputation: 8 (100%) |

just get some 2.25 in aluminized steal or stainless steal piping.

youll need around 1 J bend. 8 90deg bends and 2 -3 45 degs. then some t-bolt clamps and couplers. it takes a full day to do it because the piping isint easy to cut with a normal pipe cutter. -------------------- 15PSI - 30MPG - Megasquirt Tuned

|

Jul 14, 2005 - 3:38 AM Jul 14, 2005 - 3:38 AM

|

|

|

Enthusiast     Joined Jul 10, '05 From Monroe, WA Currently Offline Reputation: 6 (100%) |

QUOTE(lagos @ Jul 12, 2005 - 10:10 PM) just get some 2.25 in aluminized steal or stainless steal piping. youll need around 1 J bend. 8 90deg bends and 2 -3 45 degs. then some t-bolt clamps and couplers. it takes a full day to do it because the piping isint easy to cut with a normal pipe cutter. [right][snapback]311787[/snapback][/right] does anyone have step by step pics of this being done? Id like to do it to my 94' ST w/3s-gte as well. -------------------- 94' ST Coupe - 5sfe Motor swap and brake swap.

|

Jul 15, 2005 - 8:47 AM Jul 15, 2005 - 8:47 AM

|

|

|

Enthusiast    Joined May 1, '03 From Michigan Currently Offline Reputation: 0 (0%) |

A chop saw with a nice cutting wheel is your friend!

First off - clock the turbo! I dont know why people here aren't doing it on thier swaps. You pull a pin, rotate the compressor housing down, route the edge where the pin will be and make a bracket to hold the wastegate. Then the turbo is pointing downward and you dont have a big funky 180 degree turn going over the exhaust manifold. This keeps the air cooler, you save like 10 Feet of piping ( every 90 degree bend it the equiv of like 3 feet of straight pipe) and you shorten the overall path of to the throttle body - making the turbo even more responsive. Its definately worth the time. For the rest of the pipes - just order 2 or 3 U bends from JC Whitney or Summit - make sure its aluminized steel (or stainless - depending on what you can weld). Then you need a couple of silicone hump hoses and couplings. Get a buddy who can weld and go to town! This post has been edited by scothaniel: Jul 15, 2005 - 8:48 AM -------------------- Scott

West Michigan |

Jul 18, 2005 - 12:49 AM Jul 18, 2005 - 12:49 AM

|

|

|

Enthusiast     Joined Jan 29, '04 From Brooklyn moved to Miramar Florida Currently Offline Reputation: 2 (100%) |

you can go to a muffler shop & get it donn....

|

Jul 18, 2005 - 1:48 AM Jul 18, 2005 - 1:48 AM

|

|

|

Enthusiast      Joined Mar 31, '04 From Summerville, SC Currently Offline Reputation: 5 (100%) |

QUOTE(scothaniel @ Jul 15, 2005 - 1:47 PM) First off - clock the turbo! I dont know why people here aren't doing it on thier swaps. You pull a pin, rotate the compressor housing down, route the edge where the pin will be and make a bracket to hold the wastegate. Then the turbo is pointing downward and you dont have a big funky 180 degree turn going over the exhaust manifold. This keeps the air cooler, you save like 10 Feet of piping ( every 90 degree bend it the equiv of like 3 feet of straight pipe) and you shorten the overall path of to the throttle body - making the turbo even more responsive. Its definately worth the time. Word.

-------------------- -Dr Tweak, 6GC's resident engine swap wiring expert extraordinaire Click here to see my swaps drtweak@phoenixtuning.com |

Jul 21, 2005 - 3:49 AM Jul 21, 2005 - 3:49 AM

|

|

|

Enthusiast   Joined Jan 16, '04 From sydney australia Currently Offline Reputation: 0 (0%) |

id like to know how the pipework comes from the cooler..... what route does it take..... pics would be good.....

--------------------  312whp with more to come.... |

|

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: August 1st, 2025 - 9:46 AM |