Sep 11, 2007 - 6:13 PM Sep 11, 2007 - 6:13 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

So obviously my oil problem is only getting worse, I decided it's finally time to do something about it.

so I went and picked up Defgeph's old 7A... 177,000 miles and was begining to use some oil before he swapped and it sat in the garage for 2 years. but since I was getting it for free from a friend I decided to pick it up and hope for the best...  so I picked it up Fri (8/24) and the next day it came with me to work (I work at a Toyota dealer) where they unloaded it into the brake lathe room and it stayed hidden for a while. this past Saturday (9/8) me and one of the techs began tearing it apart. I was pleasantly surprised to find that it is actually in incredibly good condition for its age... I will be spending close to $500 in parts replacing every bearing, seal, gasket, etc that we can think of. What I need from you guys are your suggestions as to what I can do to make this motor a little stronger and better flowing. I'm keeping the stock pistons and considering bigger cams and having the head machined. We work for about an hour each morning before customers start coming in. Between Sat, Mon, and Tues (today) we have everything pretty much apart (except for the valves since I haven't decided to send them to the machinist with the head or not yet). This is a huge learning process for me and happy to have the oppotunity to do it. I'll add more pics and info so maybe some of you can learn some things too. This post has been edited by hurley97: Mar 6, 2008 - 9:09 PM -------------------- |

|

Replies

(1 - 99)

Sep 11, 2007 - 6:26 PM Sep 11, 2007 - 6:26 PM

|

|

Enthusiast      Joined Apr 20, '06 From Florida Currently Offline Reputation: 44 (100%) |

My suggestion if you want some seirous power would be NOS. mos Def like a 100 or 150 shot. yeaa. nos..

maybe a couple stickers to help with the throttle response too. and def get some of those turbonator eletric turbo things from ebay, they are rated for like 30 hp! I take it the new job is going well? Looking forward to reading this thread (You should tuck your bay when the engine is out This post has been edited by jcbass7: Sep 11, 2007 - 6:28 PM |

Sep 11, 2007 - 8:21 PM Sep 11, 2007 - 8:21 PM

|

|

|

Moderator      Joined Oct 1, '02 From fall river, ma Currently Offline Reputation: 13 (100%) |

shave the head a bit, 3 angle valve job, MAYBE a light port, ported TB+ IM, exhaust, intake, a little SAFC tuning.. and hey, you may make 115whp or so steff.

fun project, ill be looking forward to up close updates! -------------------- Former Team 5SFTE pro member ;)

13.6@108MPH, 5SFTE Powered |

Sep 11, 2007 - 9:11 PM Sep 11, 2007 - 9:11 PM

|

|

|

Enthusiast     Joined Aug 23, '05 From Princeton, Minnesota Currently Offline Reputation: 7 (100%) |

OOOH BOY!! Ive been looking forward to this project. Some suggestions I have are shotpeened rods($60 is what i paid), umm i had an idea but i forgot it, im sure it will come up some other time.

Good luck on the project -------------------- -Brian

|

Sep 11, 2007 - 9:13 PM Sep 11, 2007 - 9:13 PM

|

|

Enthusiast      Joined Apr 20, '06 From Florida Currently Offline Reputation: 44 (100%) |

QUOTE(presure2 @ Sep 11, 2007 - 9:21 PM) [snapback]595255[/snapback] shave the head a bit, 3 angle valve job, MAYBE a light port, ported TB+ IM, exhaust, intake, a little SAFC tuning.. and hey, you may make 115whp or so steff. fun project, ill be looking forward to up close updates! I agree, when i shaved my head i gained atleast a couple tenths in the quarter... then i shaved my legs but didn't notice as much of an increase But seriously, im excited about this thread, and i like manny's ideas above^ |

Sep 11, 2007 - 9:13 PM Sep 11, 2007 - 9:13 PM

|

|

|

Enthusiast     Joined Oct 18, '06 From cincinnati Currently Offline Reputation: 10 (100%) |

turbo?

-------------------- proud =3sgte SWAPPED= '95 Celica ST owner [calling it the GT2 or half-trac]

309,000 miles n' .... |

Sep 11, 2007 - 9:29 PM Sep 11, 2007 - 9:29 PM

|

|

|

Enthusiast      Joined Aug 11, '07 From Corona, CA Currently Offline Reputation: 4 (100%) |

head swap?

--------------------  Pandelica 2.0 in progress. |

Sep 11, 2007 - 9:54 PM Sep 11, 2007 - 9:54 PM

|

|

|

Enthusiast     Joined Oct 7, '06 From wyomissing pennsylvania Currently Offline Reputation: 2 (100%) |

since your prolly gonna have this car as a DD i wouldn't recommend going wild with cams as it lessens the drive ability of the car, open up the head some, if you have access to or know someone who builds engines you could have them freshen up the lower end to whatever degree your looking to spend on it. if i were you, id also clean the HECK outta the engine and paint it up, maybe a flat black block and head then a dark green valve cover to match the body of the car, also do the im along with them heat shield in black too.

performance, as i stated before this company called alabama heads does some good work, you could send the one you have to them and have them do whatever work you'd like to whatever spec, and also they can put some new parts in too for longer life. get some high comp pistons, but not too crazy. also get a stronger clutch for more fun shifting. and possibly a lighter flywheel, but again for drive ability, not too light with too strong of a clutch -------------------- you know why they put sheep at the edge of a cliff.... that way they push back!

(2:27:32 AM) edit: please f*cking work, f*ck, sh*t, piss (2:28:08 AM) edit: that did the trick |

Sep 11, 2007 - 10:35 PM Sep 11, 2007 - 10:35 PM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

have it all balanced, that'll make it run alot smoother and make it a more pleasant car to drive.

-------------------- |

Sep 12, 2007 - 9:17 AM Sep 12, 2007 - 9:17 AM

|

|

|

Enthusiast      Joined May 22, '03 From NOVA Currently Offline Reputation: 16 (100%) |

knife edge the crank.

you wana lighten up the bottom end as much as possible, this will give better acceleration (less rotational mass) and better throttle response. and as previously stated, balance everything and have the head opened up. though i'd leave the cams alone. it wouldn't be worth the $ oh and run a thinner head gasket if you can or if there is enough combustion chamber room, have the head milled down slightly to raise the compression a bit. This post has been edited by playr158: Sep 12, 2007 - 9:20 AM |

Sep 12, 2007 - 9:35 AM Sep 12, 2007 - 9:35 AM

|

|

|

Enthusiast      Joined Mar 15, '07 From Tennessee Currently Offline Reputation: 52 (100%) |

QUOTE(hurley97 @ Sep 11, 2007 - 7:13 PM) [snapback]595228[/snapback] So obviously my oil problem is only getting worse, I decided it's finally time to do something about it. so I went and picked up Defgeph's old 7A... 177,000 miles and was begining to use some oil before he swapped and it sat in the garage for 2 years. but since I was getting it for free from a friend I decided to pick it up and hope for the best...  so I picked it up Fri (8/24) and the next day it came with me to work (I work at a Toyota dealer) where they unloaded it into the brake lathe room and it stayed hidden for a while. this past Saturday (9/8) me and one of the techs began tearing it apart. I was pleasantly surprised to find that it is actually in incredibly good condition for its age... I will be spending close to $500 in parts replacing every bearing, seal, gasket, etc that we can think of. What I need from you guys are your suggestions as to what I can do to make this motor a little stronger and better flowing. I'm keeping the stock pistons and considering bigger cams and having the head machined. We work for about an hour each morning before customers start coming in. Between Sat, Mon, and Tues (today) we have everything pretty much apart (except for the valves since I haven't decided to send them to the machinist with the head or not yet). This is a huge learning process for me and happy to have the oppotunity to do it. I'll add more pics and info so maybe some of you can learn some things too. love the steering wheel..... -------------------- Learned a lot in 10 years... I hardly log in anymore, last login Today Sept 6 2019, and I was forced just to clarify a post. LOL

If you PM me and I dont respond, dont fret or cry. Im alive, better post your questions in the thread below, maybe I log back in 2grfe Swapped... Why I chose the 2GR, before you ask read here... A great civilization is not conquered from without until it has destroyed itself from within. @llamaraxing in Instagram is the best way to find me. I hardly log here anymore. |

Sep 12, 2007 - 9:49 AM Sep 12, 2007 - 9:49 AM

|

|

Enthusiast      Joined Dec 16, '02 From New York Currently Offline Reputation: 4 (100%) |

Steff I'm really excited to read this thread as you do this rebuild.

My request is a pic of how clean Jeff's engine is. Also- did they figure out why his was burning oil? -------------------- Buy my Celica $2,500 - http://www.6gc.net/forums/index.php?showtopic=76562&st=0

|

Sep 12, 2007 - 1:07 PM Sep 12, 2007 - 1:07 PM

|

|

|

Enthusiast      Joined Aug 11, '07 From Corona, CA Currently Offline Reputation: 4 (100%) |

wow..our engine is tiny. good grief.

good luck! i hope all these suggestions work to your favor for your celi --------------------  Pandelica 2.0 in progress. |

Sep 12, 2007 - 1:57 PM Sep 12, 2007 - 1:57 PM

|

|

Enthusiast   Joined Dec 3, '04 From torrance, ca Currently Offline Reputation: 0 (0%) |

Awesome, the 7A actually fits in the front seats lol. Goodluck with the build, only thing I could think of is to get the engine balanced and to do a 3 or 5 angle valve job and port and polish the intake and exhaust and match that with the manifolds so it would breathe better.

|

Sep 12, 2007 - 3:28 PM Sep 12, 2007 - 3:28 PM

|

|

Enthusiast      Joined Nov 12, '02 From Webster Ma. Currently Offline Reputation: 1 (100%) |

you can do all thats listed above ^ great suggestions.

with the head shaved, and advanced timing 93 octane would be a requirement. gasket match/port everything. light weight flywheel. adjustable cam gears possible gains there, rather than aftermarket shafts. Oh and a thermal barrier intake manifold gasket. maybe add another 7a to power the rear wheels too. This post has been edited by x_itchy_b_x: Sep 12, 2007 - 3:32 PM -------------------- |

Sep 12, 2007 - 3:30 PM Sep 12, 2007 - 3:30 PM

|

|

|

Enthusiast      Joined May 22, '03 From NOVA Currently Offline Reputation: 16 (100%) |

QUOTE(x_itchy_b_x @ Sep 12, 2007 - 4:28 PM) [snapback]595484[/snapback] you can do all thats listed above ^ great suggestions. with the head shaved, and advanced timing 93 octane would be a requirement. gasket match/port everything. light weight flywheel. adjustable cam gears possible gains there, rather than aftermarket shafts. maybe add another 7a to power the rear wheels too. adjustable cam is a very gray area, since the 7afe works on a Slave cam style setup, you can't change the cam gears individually |

Sep 12, 2007 - 3:48 PM Sep 12, 2007 - 3:48 PM

|

|

Moderator      Joined Apr 17, '03 From Rockland NY Currently Offline Reputation: 15 (100%) |

I believe she will be building this engine for a turbo set up in the future.

Bumping up compression would not be a good idea. Rebuild, valve job, & port the head. Port match the intake & exhaust manifolds. Grind the cast markings off the head ports and combustion chambers. Lightweight flywheel with a street clutch. See if you can find someone to shave some weight off the crank. Look into new cams or regrinds. Don't bother with the gear. Put that turbo kit in, you'll have some nice results. Can't wait to see how this project unfolds! --------------------  I will return one day. |

Sep 12, 2007 - 4:01 PM Sep 12, 2007 - 4:01 PM

|

|

|

Moderator      Joined Oct 1, '02 From fall river, ma Currently Offline Reputation: 13 (100%) |

QUOTE(Defgeph @ Sep 12, 2007 - 4:48 PM) [snapback]595496[/snapback] I believe she will be building this engine for a turbo set up in the future. Bumping up compression would not be a good idea. Rebuild, valve job, & port the head. Port match the intake & exhaust manifolds. Grind the cast markings off the head ports and combustion chambers. Lightweight flywheel with a street clutch. See if you can find someone to shave some weight off the crank. Look into new cams or regrinds. Don't bother with the gear. Put that turbo kit in, you'll have some nice results. Can't wait to see how this project unfolds! hehe totally forgot about the turbo down the road, jeff..lol nix the shaven head. do they make a metal headgasket for the 7a? -------------------- Former Team 5SFTE pro member ;)

13.6@108MPH, 5SFTE Powered |

Sep 12, 2007 - 4:07 PM Sep 12, 2007 - 4:07 PM

|

|

Moderator      Joined Apr 17, '03 From Rockland NY Currently Offline Reputation: 15 (100%) |

We could have one made. I'd like to make one twice as thick as stock.

--------------------  I will return one day. |

Sep 12, 2007 - 6:13 PM Sep 12, 2007 - 6:13 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

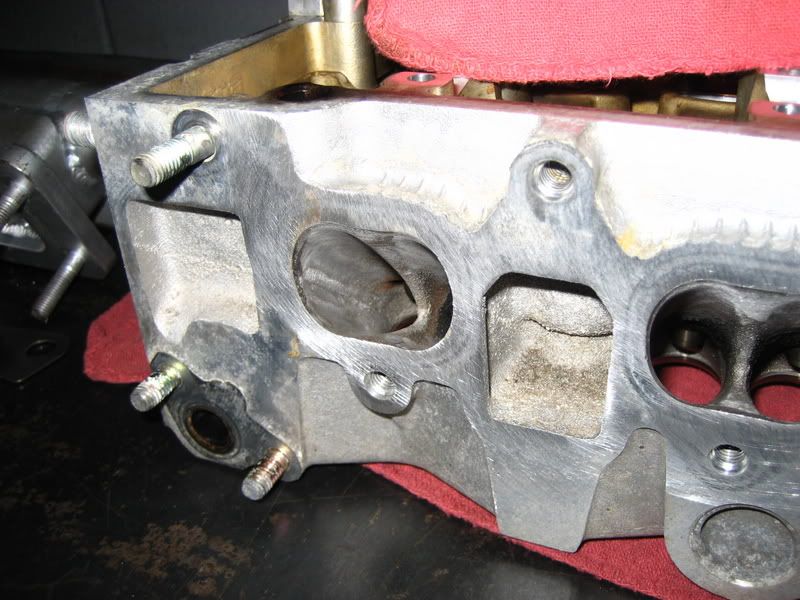

QUOTE(presure2 @ Sep 12, 2007 - 5:01 PM) [snapback]595500[/snapback] hehe totally forgot about the turbo down the road, jeff..lol nix the shaven head. do they make a metal headgasket for the 7a? believe it or not Manny the OEM 7A headgasket is metal anyway, I know everyone wants to see pictures... First we separated the head and the block like I said Jeff's engine is incredibly clean and I wouldn't have believed it has 177k miles on it [looking at the picture below] I want to know what I can and can't shave off/ smooth out on the head    and the block  ^notice the dirty pistons above, soon there will be a picture of them cleaned up a little now with the pistons out    -------------------- |

Sep 12, 2007 - 6:28 PM Sep 12, 2007 - 6:28 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

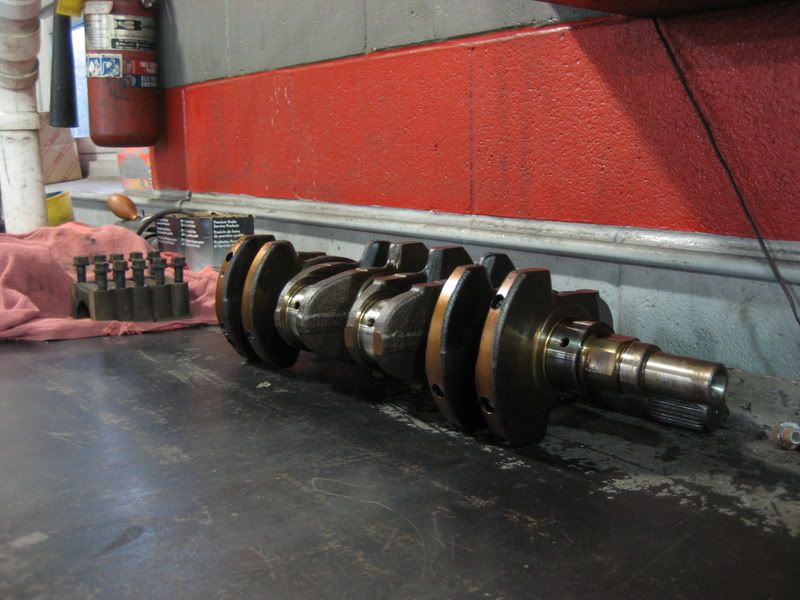

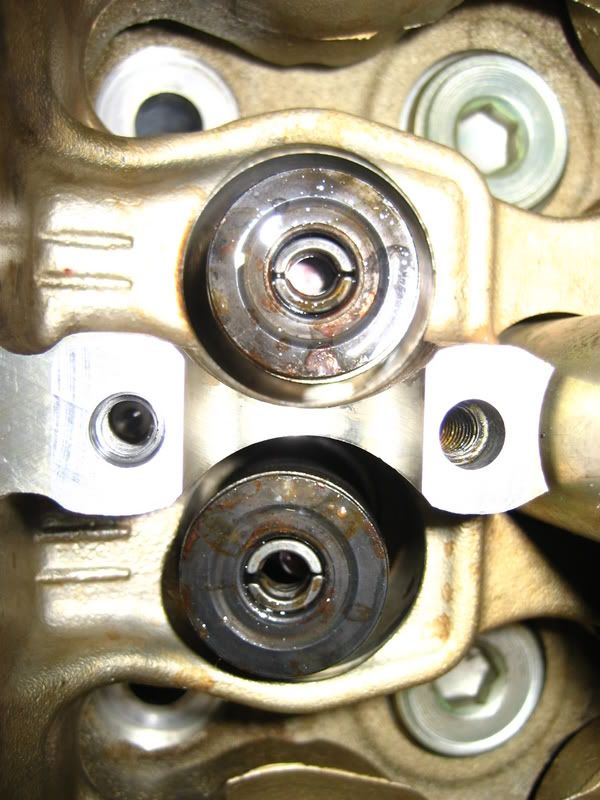

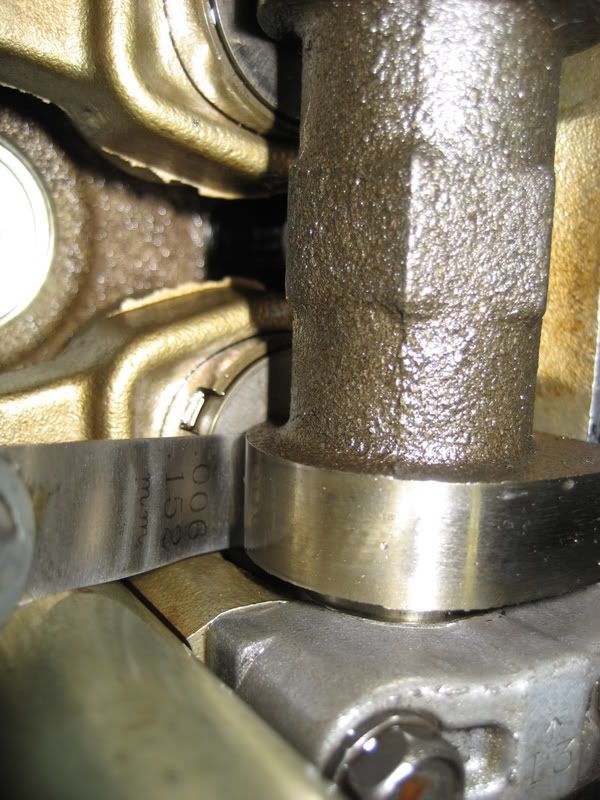

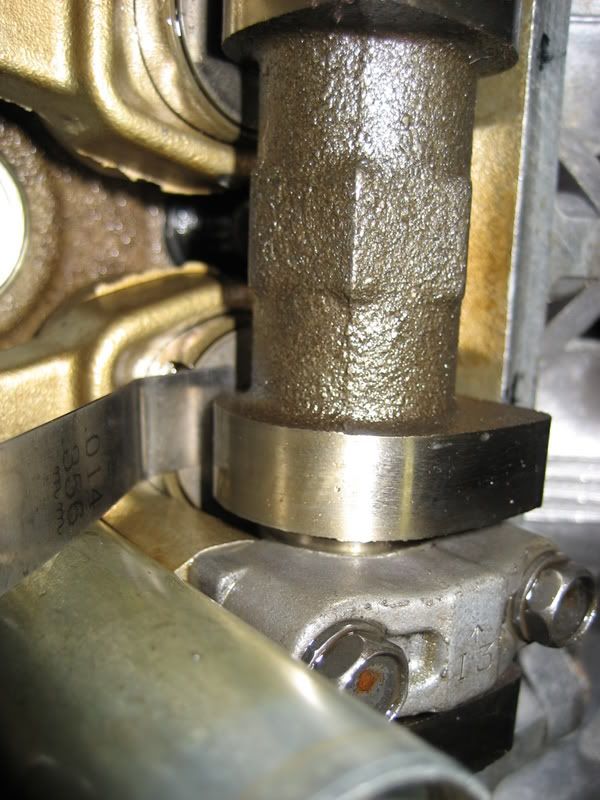

QUOTE(ILuvMyCelica95 @ Sep 12, 2007 - 10:49 AM) [snapback]595394[/snapback] Also- did they figure out why his was burning oil? yes. things that were wrong with the engine: 1. the oil control rings were just old and worn and got gummed up with oil so they sunk into the piston and since they didn't sit where they should oil just went right past them and got burned on the cylinder walls. the oil control rings...  sit in the bottom groove of the pistons...  and are held in place by another ring similar to the compression rings (shown below. they go in the two top grooves in the orientation shown) but are a little thinner  2. the thrust bearing was a little worn and had some play. this was just due to the added strain on the crank from it being attached to a manual transmission. the thrust bearing...  sits on either side of that middle seat in the grooves on either side  all the other bearings and seals were in pretty good shape, although I am still going to replace them all -------------------- |

Sep 12, 2007 - 7:02 PM Sep 12, 2007 - 7:02 PM

|

|

Enthusiast      Joined Nov 12, '02 From Webster Ma. Currently Offline Reputation: 1 (100%) |

awesome! thats a pretty big crank, i was surprised. very clean, esp the head.

you guys arent waisting any time either jeeze. -------------------- |

Sep 12, 2007 - 7:45 PM Sep 12, 2007 - 7:45 PM

|

|

Moderator      Joined Apr 17, '03 From Rockland NY Currently Offline Reputation: 15 (100%) |

Thats awesome ! This is a project I have been wanting to do for years. I'm happy to have donated my engine to your cause

Keep the thread flowing like this. Its great to see what was the original problem, and what other parts started to fail because of it. Take pictures of the intake and exhaust posts on the head once you've cleaned them up. Also, take pics of the bottom of the head. Nice thread --------------------  I will return one day. |

Sep 12, 2007 - 8:25 PM Sep 12, 2007 - 8:25 PM

|

|

|

Enthusiast      Joined Aug 31, '02 From Philadelphia, PA Currently Offline Reputation: 8 (100%) |

im going to take a guess and say you used mobil1, jeff?

-------------------- 15PSI - 30MPG - Megasquirt Tuned

|

Sep 12, 2007 - 9:06 PM Sep 12, 2007 - 9:06 PM

|

|

Moderator      Joined Apr 17, '03 From Rockland NY Currently Offline Reputation: 15 (100%) |

ON A 7A! Are you crazy ? Just used regular sludge for that engine.

--------------------  I will return one day. |

Sep 12, 2007 - 9:19 PM Sep 12, 2007 - 9:19 PM

|

|

Enthusiast    Joined Mar 28, '04 From St.Louis Currently Offline Reputation: 15 (100%) |

hey, this is very interesting for me cuse i am on the same route, how much NA power can u get out of a 7a. Well i really look forward to seeing pics of your progress. Hope all goes well. My two cents, if you have the money send the head of to Extrude Hone, its a process where they push an abrassive material through the entire head (Intake and Exhaust) and it polishes the sharp edges, increases flow and helps for breathing, the process costs $650 for our head, ive called them before to find out. Let me know if you need more info. Good luck

Matt --------------------  1994 GT Hatchback 1994 ST Coupe 1988 Corolla Wagon All-Trac 1999 Corvette 2008 Cobalt SS Turbo |

Sep 12, 2007 - 10:32 PM Sep 12, 2007 - 10:32 PM

|

|

|

Enthusiast      Joined Jul 7, '03 Currently Offline Reputation: 55 (100%) |

I can't wait to see how this turns out. Looks like fun.

-------------------- JDM guy made me do it.

|

Sep 12, 2007 - 11:29 PM Sep 12, 2007 - 11:29 PM

|

|

|

Enthusiast      Joined Aug 31, '02 From Philadelphia, PA Currently Offline Reputation: 8 (100%) |

QUOTE(Defgeph @ Sep 12, 2007 - 10:06 PM) [snapback]595593[/snapback] ON A 7A! Are you crazy ? Just used regular sludge for that engine. and it looks that good? crazy. guess all the oil brand debates just got thrown out the window. -------------------- 15PSI - 30MPG - Megasquirt Tuned

|

Sep 12, 2007 - 11:39 PM Sep 12, 2007 - 11:39 PM

|

|

|

Enthusiast      Joined Aug 31, '02 From Philadelphia, PA Currently Offline Reputation: 8 (100%) |

stef, i dont know how crazy you want to go with this build up, but if you are really planning to turbo, i would upgrade the pistons, rods, and headgasket, and do the cam regrinds, as well as replacing any rubber seal/gasket. then you would have a strong and nice flowing motor thats ready for the abuse of a turbocharger.

-------------------- 15PSI - 30MPG - Megasquirt Tuned

|

Sep 12, 2007 - 11:58 PM Sep 12, 2007 - 11:58 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

QUOTE(94celicadude @ Sep 12, 2007 - 10:19 PM) [snapback]595597[/snapback] hey, this is very interesting for me cuse i am on the same route, how much NA power can u get out of a 7a. Well i really look forward to seeing pics of your progress. Hope all goes well. My two cents, if you have the money send the head of to Extrude Hone, its a process where they push an abrassive material through the entire head (Intake and Exhaust) and it polishes the sharp edges, increases flow and helps for breathing, the process costs $650 for our head, ive called them before to find out. Let me know if you need more info. Good luck Matt wow... thats an insane price for that. we already did that this morning, took about 20 mins. I'll have pictures soon. I spoke to a friend of another tech about machining the head and it sounded like all he was going to do was clean it and make it look pretty and charge me $70. its not that dirty, we can clean it at work. if we have the right tools to port match the intake and exhaust we'll do that ourselves too. I can't imagine a 5 angle valve job being too precise either in which case we can probably do that too. we'll see how it goes -------------------- |

Sep 13, 2007 - 12:11 AM Sep 13, 2007 - 12:11 AM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

to find the size of the main bearings...

for the crankshaft...  there are 5 numbers engraved on the corner of the block (top and bottom)....  that correspond to 5 numbers engraved on the crankshaft itself...  you add the number on the crank to the corresponding number on the block. no number means 0. so the 01 on the crank pictured combines with the 2 printed on the block to come up with a #3 bearing. -------------------- |

Sep 13, 2007 - 2:54 AM Sep 13, 2007 - 2:54 AM

|

|

|

Enthusiast  Joined Apr 16, '06 From Melbourne, Australia Currently Offline Reputation: 0 (0%) |

that's looks amazing, makes we wonder why i didn't pick up to being a mechanic, regretting it now, but that's looks awesome

--------------------  |

Sep 13, 2007 - 6:08 PM Sep 13, 2007 - 6:08 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

I cleaned and painted the block yesterday...

and we honed the cylinders. I don't have a picture of the tool we used but it looks like a bunch of wire bristles with balls on the end attached to a drill. you have to break the glaze on the cylinder walls in a crosshatch kind of pattern so the oil sticks better...  and today we just re-ringed the pistons..  there are two thin rings that go above and below the oil control rings in the bottom groove and the top two are the compression rings. you want to place the openings in the rings on alternating sides and always right above the wrist pin since that takes the least stress. so in the picture the opening in the ring under the oil control ring is facing back, the one on top is facing forward, the first compression ring facing back (there is a "2R" written on it that should be facing up), and the top ring facing front. they fit very loose like that so as to make a tighter seal with the cylinder wall when installed.  we can't do much else until the main bearings come in (probably Monday) since we need them to put the bottom end back together. we want to finish the bottom completely before starting on the head, just to keep things organized. This post has been edited by hurley97: Sep 13, 2007 - 6:10 PM -------------------- |

Sep 13, 2007 - 6:22 PM Sep 13, 2007 - 6:22 PM

|

|

|

Enthusiast     Joined Aug 23, '05 From Princeton, Minnesota Currently Offline Reputation: 7 (100%) |

if your not gonna get the pauters and want a little extra strength id shotpeen the rods while they are out. its cheap and it gives a little bit of strength to them

-------------------- -Brian

|

Sep 13, 2007 - 6:26 PM Sep 13, 2007 - 6:26 PM

|

|

|

Enthusiast      Joined Jan 28, '05 From Redondo Beach, CA Currently Offline Reputation: 86 (100%) |

reminds me of rebuilding a cummins engine, same process but cummins is like 10x bigger!

--------------------  |

Sep 13, 2007 - 7:19 PM Sep 13, 2007 - 7:19 PM

|

|

Enthusiast      Joined Jul 7, '06 From Los Alamos, NM Currently Offline Reputation: 1 (100%) |

this has to be the most interesting thread ever!

keep up the good work! -------------------- 2015 Subaru WRX. World Rally Blue/Black

2001 Honda S2000. Spa Yellow/Black |

Sep 13, 2007 - 7:34 PM Sep 13, 2007 - 7:34 PM

|

|

|

Enthusiast      Joined Jul 7, '03 Currently Offline Reputation: 55 (100%) |

I personally would check all parts with a micrometer and

make sure crank, rods, oil pump meet all specs. Thats kinda my thing though. looks a little scuffed at least in the one pic. -------------------- JDM guy made me do it.

|

Sep 13, 2007 - 9:26 PM Sep 13, 2007 - 9:26 PM

|

|

Enthusiast      Joined Apr 20, '06 From Florida Currently Offline Reputation: 44 (100%) |

Steff this thread is awesome! keep it up

|

Sep 14, 2007 - 9:02 AM Sep 14, 2007 - 9:02 AM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

QUOTE(lagos @ Sep 13, 2007 - 12:39 AM) [snapback]595641[/snapback] stef, i dont know how crazy you want to go with this build up, but if you are really planning to turbo, i would upgrade the pistons, rods, and headgasket, and do the cam regrinds, as well as replacing any rubber seal/gasket. then you would have a strong and nice flowing motor thats ready for the abuse of a turbocharger. from what I hear the pistons and rods will more than stand up to the abuse of a turbo (I'll save that for when I rebuild the engine thats in my car since it'll be much worse and probably need a re-bore anyway), the head gasket is already metal, I will be replacing any and all seals/ bearings I possbily can, this is going to be like a brand new engine when it goes in, I do want to smooth out the head some to make it flow better, right now I'm thinking about the bigger cams. WebCams has done a grind for the 7A before and it would cost about $575 and about 3 weeks. Reasons I'm not sure about them right now is 1, they cost more than the rebuild parts 2, I'm not sure if I want this engine to sit at work for another couple weeks and 3, I really don't know how they will affect the car since they tell me it has only been done twice before. Also, what I kind of want to do is dyno the stock re-built 7A, then with just the cams, then the turbo. still thinking about it... -------------------- |

Sep 14, 2007 - 9:12 AM Sep 14, 2007 - 9:12 AM

|

|

Enthusiast      Joined Dec 16, '02 From New York Currently Offline Reputation: 4 (100%) |

Steff i love this i feel like im in class

I wish i had someone around to learn off of, this is a GREAT opportunity. -------------------- Buy my Celica $2,500 - http://www.6gc.net/forums/index.php?showtopic=76562&st=0

|

Sep 14, 2007 - 9:13 AM Sep 14, 2007 - 9:13 AM

|

|

|

Enthusiast      Joined May 22, '03 From NOVA Currently Offline Reputation: 16 (100%) |

4ag(z)e head gaskets will work also (i do believE)

|

Sep 14, 2007 - 10:13 AM Sep 14, 2007 - 10:13 AM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

yes you probably could but the 7A headgasket is metal so I can just use that

-------------------- |

Sep 14, 2007 - 11:10 AM Sep 14, 2007 - 11:10 AM

|

|

|

Enthusiast      Joined Oct 13, '02 From Blairstown, New Jersey Currently Offline Reputation: 6 (100%) |

Stef, good to see that you're on your way with the project.

I think a pretty modest increase in the I/E duration of the camshafts wouldn't be a bad idea, as long as its not so agressive that it affects the off-boost performance alot. Maybe keep the same proportion as the stock camshafts, just increase their duration slightly to allow more compressed air in, more exhaust gasses out per cycle but with good drivability? Between a rebuilt and ported top-end, camshafts, and perhaps using some uprated 4AGE/4AGZE valve springs with the proper shims to prevent any float from the reworked head when it sees boost, you would have an awesome setup. Looks great so far Stef, I don't think you're going to need alot of our advice with the build. It looks like you have the best help you can get with the rebuild and you already have a solid start on the bottom end. Best of luck, I'll see you on the dark side...of boost. -------------------- 3rd gen ST205 3SGTE - Alive and boosting. |

Sep 14, 2007 - 12:09 PM Sep 14, 2007 - 12:09 PM

|

|

|

Enthusiast Joined Jun 29, '07 From Fall River, MA Currently Offline Reputation: 0 (0%) |

QUOTE Between a rebuilt and ported top-end, camshafts, and perhaps using some uprated 4AGE/4AGZE valve springs with the proper shims to prevent any float from the reworked head when it sees boost, you would have an awesome setup that would also allow you to rev a bit higher as well, as long as the stock rod bolts can take it. whoops manny posting as brennton on moms puter...lol --------------------  |

Sep 16, 2007 - 4:03 AM Sep 16, 2007 - 4:03 AM

|

|

|

Enthusiast      Joined Oct 13, '02 From Blairstown, New Jersey Currently Offline Reputation: 6 (100%) |

QUOTE as long as the stock rod bolts can take it. Haha. Lets put it to the test! -------------------- 3rd gen ST205 3SGTE - Alive and boosting. |

Sep 17, 2007 - 9:39 AM Sep 17, 2007 - 9:39 AM

|

|

|

Enthusiast  Joined Nov 29, '06 From Newnan, Ga. Currently Offline Reputation: 3 (100%) |

Nice pics!

|

Sep 17, 2007 - 11:30 AM Sep 17, 2007 - 11:30 AM

|

|

Enthusiast   Joined Dec 12, '06 From Fob Sharana, Afghanistan Currently Offline Reputation: 2 (100%) |

QUOTE(Silver94CelicaOwner @ Sep 16, 2007 - 5:03 AM) [snapback]596416[/snapback] QUOTE as long as the stock rod bolts can take it. Haha. Lets put it to the test! I always thought the stock rods on a 7A were weaker but has a bigger stroke. |

Sep 19, 2007 - 6:51 PM Sep 19, 2007 - 6:51 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

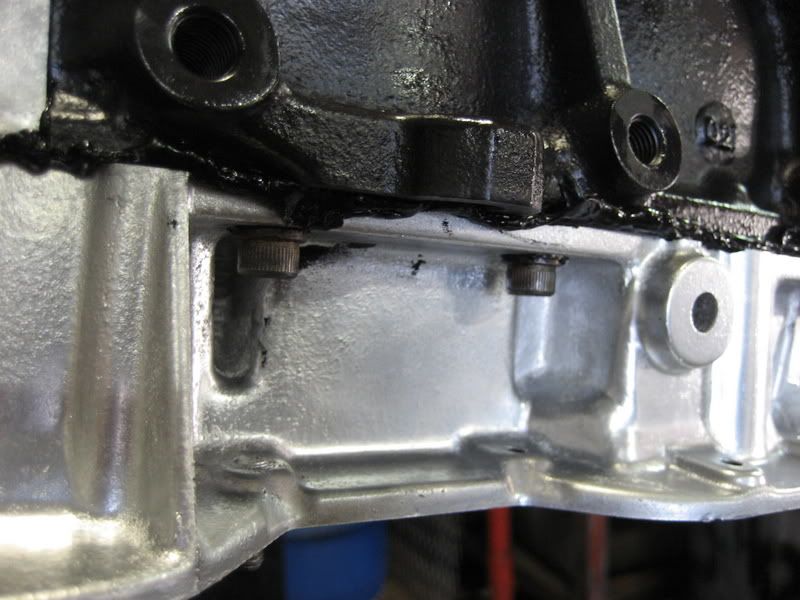

QUOTE(Silver94CelicaOwner @ Sep 16, 2007 - 5:03 AM) [snapback]596416[/snapback] QUOTE as long as the stock rod bolts can take it. Haha. Lets put it to the test! oh you know I will Corey Finally! the main bearings came in and we got back to work... There are two sides to each main bearing, one is smooth and the other has a groove and a hole in it. remember these bearings corresponded to the number ont he crankshaft + the number on the block, I had four #3 bearings and one number 2, so here you have to make sure you put the bearings where they belong. the smooth half goes on the caps that hold the crankshaft in, there are little notches in the bearing that match up with a notch on the cap, you can see them on the two caps all the way to the right in the pic...  the other side of the bearing goes on the block itself and lines up with the journal hole and the same kind of notch as on the cap...  the middle bearing seat also contains the thrust washers. there are four of them in the set, two with little tabs and two without. there are also two side to each of them, one side is smooth and the other has some sort of material on it (sort of like a brake pad). the two without the tabs go on the block, we put some vasaline on the smooth side and stuck it to the indentations provided with the material side facing outward...  the two with the tabs go on the cap in the same orientation, vasaline on it and smooth side in...  then we oiled up all the bearings and placed the crankshaft back in place.  then oiled up the bearings on the caps and put some oil on the bolt threads as well before putting the caps on and torquing them down to 44 ft/lbs next was the rear main seal and the crankshaft seal. hammered the seals flush with the housing, put some FIPG (Form In Place Gasket) on each side of the regular gasket, lubed up the inner part of each seal, then put them in place and bolted them in.  And that was it for today. Pistons and top part of the oil pan are going in tomorrow morning and that will pretty much be all for the bottom end. -------------------- |

Sep 19, 2007 - 9:16 PM Sep 19, 2007 - 9:16 PM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

-------------------- |

Sep 19, 2007 - 9:55 PM Sep 19, 2007 - 9:55 PM

|

|

Enthusiast      Joined Feb 7, '03 From Northern Virginia Currently Offline Reputation: 23 (100%) |

wow are you keeping all the receipts and costs tallied? i want to know how much it is as i have a 7a in my garage that needs some tlc

nice job so far btw |

Sep 19, 2007 - 11:47 PM Sep 19, 2007 - 11:47 PM

|

|

Moderator      Joined Apr 17, '03 From Rockland NY Currently Offline Reputation: 15 (100%) |

Looking good.

--------------------  I will return one day. |

Sep 19, 2007 - 11:54 PM Sep 19, 2007 - 11:54 PM

|

|

Administrator      Joined Aug 23, '02 From Seattle, WA Currently Offline Reputation: 14 (100%) |

Looks great. I love threads like this.

-------------------- New Toyota project coming soon...

|

Sep 19, 2007 - 11:59 PM Sep 19, 2007 - 11:59 PM

|

|

Enthusiast      Joined Jul 7, '06 From Los Alamos, NM Currently Offline Reputation: 1 (100%) |

QUOTE(Coomer @ Sep 19, 2007 - 11:54 PM) [snapback]597505[/snapback] Looks great. I love threads like this. X infiniti wow this truely is the most interesting thing right now! -------------------- 2015 Subaru WRX. World Rally Blue/Black

2001 Honda S2000. Spa Yellow/Black |

Sep 23, 2007 - 8:05 PM Sep 23, 2007 - 8:05 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

sorry for the delay on the progress report... that CSP meet was kind of crazy...

now for putting the pistons in... the rod bearings come in sets of 2 and both sides are the same  on the pistn rod itself there is a hole that matches up with the hole in the bearing, and just like the main bearings there is the little notch that matched up as well...  on the cap end there is not holes so you just use the little notch to place it in the right orientation...  then oil up both sides of the bearings  now if you remember from before the compression and oil control rings stick out a lot  so you need to use a ring compressor to push them in, the pistons need to be dunked in oil before this step...  now at this point you want to put in two pistons at a time (either 1 & 4 or 2 & 3) and you are going to want to push them all the way down so make sure the part of the crank the rod sits on is all the way down and straight. then we cleaned off the cylinder walls a little in case anything had gotten in there from it sitting for a while. double check to make sure the right piston is going into the right cylinder using the stamped numbers on them...  so with the ring comrpessor still on the piston you place the rod end into the cylinder and use the end of a hammer or something to gently tap the piston down into place. once its out of the ring compressor you put that aside and finish tapping it down while you kind of guide the rod end onto the crankshaft  the caps are held on by stretch bolts that need to be torqued to 44 ft/lbs then tightened another 90 degrees. so once they are torqued you mark them so you know where to stop after doing the 90 degree turn...  the cast part of the oil pan is easy, put a crap load of FIPG on and tap it a little with a hammer so it sits properly. there are a bunch of allen head bolts and some normal ones that go on the inside  put the little gear and the crank postion sensor back on...  and thats how it sits right now..

-------------------- |

Sep 23, 2007 - 8:13 PM Sep 23, 2007 - 8:13 PM

|

|

|

Enthusiast     Joined Jan 18, '07 From Bergen county NJ Currently Offline Reputation: 24 (100%) |

Looking good, nice work.....you impress me

-------------------- |

Sep 23, 2007 - 8:26 PM Sep 23, 2007 - 8:26 PM

|

|

|

Enthusiast      Joined Mar 22, '07 From Houston, TX Currently Offline Reputation: 4 (100%) |

wow. this thread amazes me.

rebuilding doesn't seem too hard now.. -------------------- QUOTE "And, as always, your friendship, help, and dedication to the advancement of Texas Celica dominance is GREATLY appreciated. Thanks bro." -DEATH 1994 GT: V6 swap, 5speed E53 W/ LSD, All Power, now RED 1995 ST: SOLD @273k miles, Auto, all power, CarPC, White 1994 ST: Totaled, 5spd, all power, Red RIP 07/09/09 @ 241,810 1994 Lexus LS400: This is my new DD |

Sep 23, 2007 - 9:19 PM Sep 23, 2007 - 9:19 PM

|

|

|

Enthusiast      Joined May 22, '03 From NOVA Currently Offline Reputation: 16 (100%) |

very nice progess.

|

Sep 23, 2007 - 9:40 PM Sep 23, 2007 - 9:40 PM

|

|

|

Enthusiast      Joined Aug 31, '02 From Philadelphia, PA Currently Offline Reputation: 8 (100%) |

HOT! not trying to be an internet mechanic here, but why aren't you using assembly lube? motor oil is ok for most stuff, but i would worry that most of it will just drip down into the pan, an you'll have little protection the first time you crank it up. This post has been edited by lagos: Sep 23, 2007 - 9:40 PM -------------------- 15PSI - 30MPG - Megasquirt Tuned

|

Sep 23, 2007 - 9:48 PM Sep 23, 2007 - 9:48 PM

|

|

|

Enthusiast      Joined Jan 28, '05 From Redondo Beach, CA Currently Offline Reputation: 86 (100%) |

for deisels we use gear oil to lube the bearings

--------------------  |

Sep 23, 2007 - 9:57 PM Sep 23, 2007 - 9:57 PM

|

|

|

Enthusiast      Joined May 22, '03 From NOVA Currently Offline Reputation: 16 (100%) |

motor oil works fine for putting pistons in, its what myself and most other people i know normally use.

|

Sep 24, 2007 - 9:23 AM Sep 24, 2007 - 9:23 AM

|

|

Enthusiast      Joined Apr 20, '06 From Florida Currently Offline Reputation: 44 (100%) |

This is amazing steff, keep it up! I'm sure you will be getting phone calls when i start tearing down the 3s

|

Sep 24, 2007 - 9:43 AM Sep 24, 2007 - 9:43 AM

|

|

|

Enthusiast     Joined Aug 23, '05 From Princeton, Minnesota Currently Offline Reputation: 7 (100%) |

QUOTE(hurley97 @ Sep 23, 2007 - 8:05 PM) [snapback]598432[/snapback] double check to make sure the right piston is going into the right cylinder using the stamped numbers on them...  -------------------- -Brian

|

Sep 24, 2007 - 9:47 AM Sep 24, 2007 - 9:47 AM

|

|

Enthusiast      Joined Apr 20, '06 From Florida Currently Offline Reputation: 44 (100%) |

is that a 3 stamped sideways in the middle of the two 2's?

|

Sep 24, 2007 - 11:14 AM Sep 24, 2007 - 11:14 AM

|

|

|

Enthusiast     Joined Aug 23, '05 From Princeton, Minnesota Currently Offline Reputation: 7 (100%) |

QUOTE(jcbass7 @ Sep 24, 2007 - 9:47 AM) [snapback]598575[/snapback] is that a 3 stamped sideways in the middle of the two 2's? It's an M i have 2 rods that have an M and 2 rods that have a U -------------------- -Brian

|

Sep 24, 2007 - 12:40 PM Sep 24, 2007 - 12:40 PM

|

|

|

Enthusiast  Joined Nov 29, '06 From Newnan, Ga. Currently Offline Reputation: 3 (100%) |

They look like match marks to me, so you don't mix up the rods and rod caps. The rods can go in any hole position when assembling.

This post has been edited by 56willysnut: Sep 24, 2007 - 12:41 PM |

Sep 24, 2007 - 4:54 PM Sep 24, 2007 - 4:54 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

QUOTE(Celiracer18 @ Sep 24, 2007 - 10:43 AM) [snapback]598573[/snapback] QUOTE(hurley97 @ Sep 23, 2007 - 8:05 PM) [snapback]598432[/snapback] double check to make sure the right piston is going into the right cylinder using the stamped numbers on them... sorry, I thought I explained it before but I can't find it so I guess I didn't... when you take the pistons out there will be a number already stamped on them, that lets you know the size of the piston. so on the block there is the set of 5 numbers that pair with the main bearings and on the opposite end a set of 4 numbers that tell the cylinder bore size. so a number 2 on the piston rod would go to a number 2 bore, I had three #2's and one #3. but unless you are getting new pistons you want to make sure the piston you take out of cylinder 1 goes back into cylinder 1, so as you take them out one by one you want to label them somehow, we stamped the number on the blank side (in a different orientation so we could tell the difference) and yes, the 'M' is a match line -------------------- |

Sep 26, 2007 - 7:02 PM Sep 26, 2007 - 7:02 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

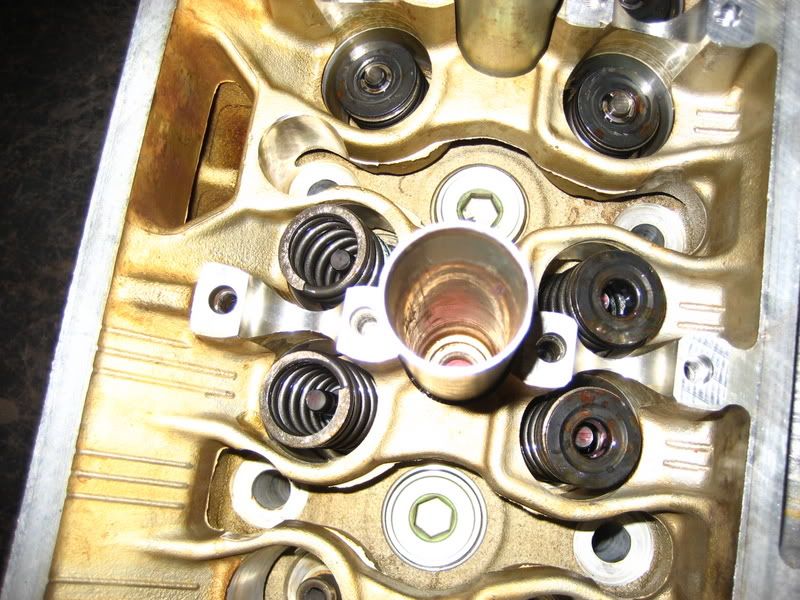

now the fun part... the top end

we started by taking the intake manifold and fuel rail off and stripping the head of everything else (i.e. EGR, brackets, sensors, valve shims) at that point to get the valve springs out you have to dislodge the keepers from their seat, there is a special tool for that but we did it a different way. tools include a hollow tube about 1/2" in diameter with a handle on it and a hammer. you just have to place the tube onto the top of the spring seat and hit the top of it pretty hard until the two little keepers come out and the spring pops up...  (beware of doing this in the car since its really easy for the tiny keepers to pop out and into one of the oil return holes) here you can see all the springs, seats, keepers, and the little washers under the springs  close up of the spring and seat...  the keepers are extremely small... I can't wait to see how we get them back in...  now the valve seals. there is a special tool for them, just grab and pull... really hard  some of the rubber from the valve seals stayed there and need to be cleaned off so the new ones snap into place properly...  at that point the valves slide right out the bottom. they have to stay in order since they have already seated to the head and if you move them they may not seal properly.  I used a wire wheel to clean the crap off the valves... that was very time consuming    -------------------- |

Sep 26, 2007 - 8:02 PM Sep 26, 2007 - 8:02 PM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

going to cut the valves and seats and then lap them?

-------------------- |

Sep 27, 2007 - 10:26 PM Sep 27, 2007 - 10:26 PM

|

|

Moderator      Joined Apr 17, '03 From Rockland NY Currently Offline Reputation: 15 (100%) |

So awesome. Keep it up Steff

--------------------  I will return one day. |

Sep 27, 2007 - 11:04 PM Sep 27, 2007 - 11:04 PM

|

|

|

Enthusiast     Joined Jul 4, '07 From US Currently Offline Reputation: 2 (100%) |

women with tools are hot ^^ there is no way of saying it a different way

|

Sep 28, 2007 - 10:38 AM Sep 28, 2007 - 10:38 AM

|

|

Enthusiast      Joined Dec 16, '02 From New York Currently Offline Reputation: 4 (100%) |

i think when this is all said and done this should be a sticky it's awesome

-------------------- Buy my Celica $2,500 - http://www.6gc.net/forums/index.php?showtopic=76562&st=0

|

Sep 28, 2007 - 10:50 AM Sep 28, 2007 - 10:50 AM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

QUOTE(Bitter @ Sep 26, 2007 - 9:02 PM) [snapback]599404[/snapback] going to cut the valves and seats and then lap them? no. I decided anything I could do to it at this point would cost a lot for very little to almost no gain. we 'ported and polished' the intake and exhaust ports as best we could and I'm pretty happy with the results. all the overkill things (boreing out the cylinders, bigger pistons, valve jobs, etc) will be done to the engine that is still in my car since it will probably be bad enough to need the extensive work, plus I'll have a lot more time before the rebuilt one needs replacing so I won't have to spend all the money at one time. This rebuilt engine probably will not be actually going into the car for a few months. I want my current engine to make it to 200k before I replace it... 8000 miles to go, so probably 5-6 months. so with that kind of time on my hand now the debate is do I want to get all the turbo stuff and put it on the engine while its out of the car then just drop in the rebuilt motor and turbo setup at once, or do I want to run the stock rebuilt 7A for a while then turbo it ? I think I'm leaning towards doing the turbo setup outside the car... thoughts ? we did put the valves back in already, I do have more pictures but I'll let you guys look those last ones over first -------------------- |

Sep 28, 2007 - 10:58 AM Sep 28, 2007 - 10:58 AM

|

|

Enthusiast      Joined Nov 12, '02 From Webster Ma. Currently Offline Reputation: 1 (100%) |

outside the car turbo setup is a great idea! heck you could even produce a JDM guy turbo kit ;P

-------------------- |

Sep 28, 2007 - 11:03 AM Sep 28, 2007 - 11:03 AM

|

|

|

Enthusiast      Joined May 22, '03 From NOVA Currently Offline Reputation: 16 (100%) |

so basically you are rebuilding this motor,

putting it in, and taking the current one out. then you are going to strip/rebuild/upgrade the motor you pull out? i'm not sure if i get the concept behind that cause having to build two motors instead of one? and doing things twice? is going to just be tossing money if this motor(the currently being rebuilt) is coming back out of the car for the motor (currently in car but going to be built?) is just going back in? why not just leave the one in there till you finish really building the one you are now, then swap them 1 time and call it done? maybe i'm miss understanding what you are doing? This post has been edited by playr158: Sep 28, 2007 - 11:04 AM |

Sep 28, 2007 - 11:36 AM Sep 28, 2007 - 11:36 AM

|

|

|

Enthusiast      Joined Jun 13, '05 From Poughkeepsie, NY Currently Offline Reputation: 2 (100%) |

U missed the point dan.

shes rebuilding this one, while she runs her current one up to 200k miles. When that happens (8ish or so months) she is gonna drop the rebuilt motor into her car. (turbo or not) got it? Steff, if your gonna rebuild the motor, and u have 8 months to do so....build up the motor, turbo it, and put down like 200whp on the 7a. You work at toyota, i bet you can find some kinda deal in 4agze Forged pistons. --------------------  Kawi Love |

Sep 28, 2007 - 12:52 PM Sep 28, 2007 - 12:52 PM

|

|

|

Enthusiast      Joined May 22, '03 From NOVA Currently Offline Reputation: 16 (100%) |

QUOTE(devilsden97 @ Sep 28, 2007 - 12:36 PM) [snapback]599855[/snapback] U missed the point dan. shes rebuilding this one, while she runs her current one up to 200k miles. When that happens (8ish or so months) she is gonna drop the rebuilt motor into her car. (turbo or not) got it? I got that much read my post.. my point of getting lost is the use of the motor that is going to 200k? "all the overkill things (boreing out the cylinders, bigger pistons, valve jobs, etc) will be done to the engine that is still in my car since it will probably be bad enough to need the extensive work, plus I'll have a lot more time before the rebuilt one needs replacing so I won't have to spend all the money at one time." ^all that is happening to the motor with 200k? i don't see why she is putting the effort into this one just to use it for a little bit while building the 200k then switching it back. saving time/money cause things will be done 2 times and motors swapped 2 times This post has been edited by playr158: Sep 28, 2007 - 12:53 PM |

Sep 28, 2007 - 1:22 PM Sep 28, 2007 - 1:22 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

I plan on keeping the car for a long time. the motor coming out of my car will be my backup, I'm planning to beat the crap out if the rebuilt turbo 7A. and the fact that it will be pretty much all stock inside I'm not sure how long it will last.

I'm not rebuilding this one just to keep it for a little while, I'm going to use the rebuilt one until it starts getting tired again. -------------------- |

Sep 28, 2007 - 1:34 PM Sep 28, 2007 - 1:34 PM

|

|

|

Enthusiast      Joined May 22, '03 From NOVA Currently Offline Reputation: 16 (100%) |

ah word gotcha cool beans!

|

Sep 29, 2007 - 8:55 PM Sep 29, 2007 - 8:55 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

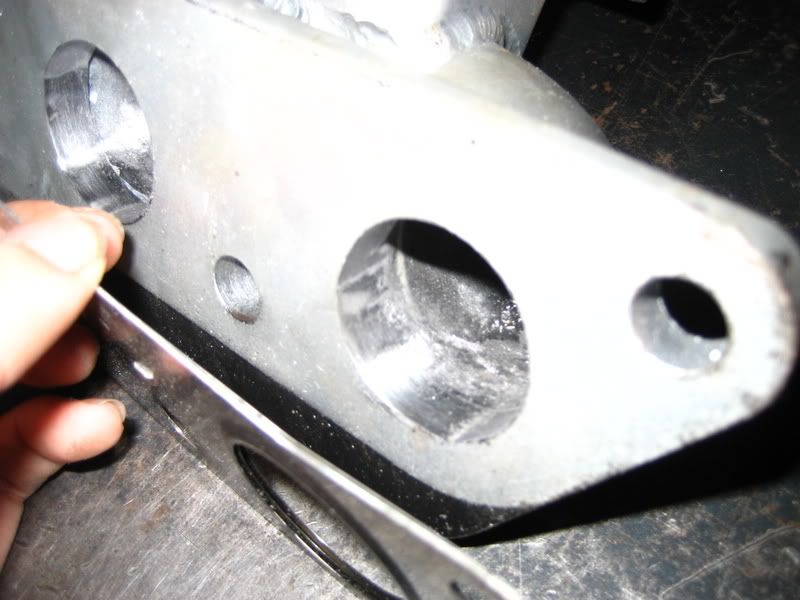

we cleaned up block and ground out the intake and exhaust ports a little...

also gasket matched the turbo manifold I bought  now to putting the valves back in. making sure to keep them in order, we did one cylinder at a time (2 intake and 2 exhaust valves) everything (washers, valves, springs, keepers, seats, etc) were soaked in oil before doing all this...  (in the pic its only half cleaned up) then placed the valve seals onto the top of the valves  then using a deep 10mm 12pt socket and extension pushed them down until you feel them almost 'snap' into place  now is the time to place the little washer in place in order to seat the valve springs and the top seat of the spring  heres the part you would have to be very careful with if you were to do this in the car. you have to hand place those tiny keepers into the top seats of the valve springs  there is a special tool for this part but I didn't get a picture of it. I'll get a pic of it if anybody really wants to know what it looks like. pushing the springs back down is the pain in the arse part of this, sometimes the keepers snap right onto the top of the valve and sometimes they don't and you have to take them back out and try again. the tech that's doing this with me likes to tap them gently with a little hammer after this part just to make sure they've seated properly.  thats all for now. just more cleaning and putting back together. its like 90% done -------------------- |

Sep 30, 2007 - 7:09 AM Sep 30, 2007 - 7:09 AM

|

|

|

Moderator      Joined Oct 1, '02 From fall river, ma Currently Offline Reputation: 13 (100%) |

that is totally bad a$$ steff. now we need to send you a 5s, and you can say you know how to rebuild BOTH!!!

gaha great work, keep it up! -------------------- Former Team 5SFTE pro member ;)

13.6@108MPH, 5SFTE Powered |

Oct 2, 2007 - 12:21 PM Oct 2, 2007 - 12:21 PM

|

|

Enthusiast  Joined May 10, '06 From El Paso, Texas Currently Offline Reputation: 1 (100%) |

are the valve seals the same in the exhaust and intake sides? im doing the same job to my head but i recieve 16 valve seals and all are the same...

|

Oct 2, 2007 - 2:28 PM Oct 2, 2007 - 2:28 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

no, the part numbers are different. the rubber part is where the main difference is.

the exhaust seals will be grayish and actually look cleaner than the intakes, the rubber part will also be darker in color. the intakes are a sort of dirty-ish metal color with a grayer rubber part. they are all the same size though. -------------------- |

Oct 2, 2007 - 4:33 PM Oct 2, 2007 - 4:33 PM

|

|

Enthusiast  Joined May 10, '06 From El Paso, Texas Currently Offline Reputation: 1 (100%) |

damn cuz i put all the same valve seals in the intake and exahust, do i need to change it? i don't want leaks thats the reason why i take my head of and port and polish it

|

Oct 2, 2007 - 5:38 PM Oct 2, 2007 - 5:38 PM

|

|

|

Enthusiast      Joined Jan 17, '04 From Illinois Currently Offline Reputation: 0 (0%) |

QUOTE(hurley97 @ Sep 28, 2007 - 1:22 PM) [snapback]599885[/snapback] I plan on keeping the car for a long time. the motor coming out of my car will be my backup, I'm planning to beat the crap out if the rebuilt turbo 7A. and the fact that it will be pretty much all stock inside I'm not sure how long it will last. I'm not rebuilding this one just to keep it for a little while, I'm going to use the rebuilt one until it starts getting tired again. As much as I hate to admit it, I have to agree with Dan on this one. It seems like alot of unneccesary work. Wouldn't you be better off just preping this motor for forced induction now and then going turbo with the same motor later? The 200,000 mile motor will make a nice door stop...or maybe some modern yard art. Kudos to you for undertaking the project. -------------------- QUOTE(lagos @ Jul 10, 2006 - 1:55 PM) [snapback]454118[/snapback] i know your trying to do the right thing for your motor, but this is one of those times where you should just trust the guys who have had their swaps for a while and have done a ton of research into this. |

Oct 2, 2007 - 7:05 PM Oct 2, 2007 - 7:05 PM

|

|

|

Enthusiast     Joined Aug 9, '06 From Ma Currently Offline Reputation: 1 (100%) |

Damn kid, looks GOOD.

You didn't mention any of this at CSP.... When Dustin does his we'll let you do all the work while we watch. It's probably a good thing you didn't touch the valve seats. Unless you have the right machine [read: a drill isn't the right way] you can screw it up. If the seat isn't perfectly machined, and the valve ground correctly you can burn the valve and/or have it not seat [won't seal]. Also, normally when the seats are reground the valve tips have to be cut, which is another time consuming PITA that requires ANOTHER special machine. Yay for engines. Use assy lube for the cam. The lobe/shim contact has alot of pressure. It's not quite as important as if it were a new engine/cams, because they're already broken into each other. But still a good idea. Personally, I use it for bearings too. I don't use it on pistons because it's so thick, and the hone will hold the residue [the rings scrape it all off anyways every time they go up and down]. QUOTE(hurley97 @ Sep 12, 2007 - 6:28 PM) [snapback]595549[/snapback] QUOTE(ILuvMyCelica95 @ Sep 12, 2007 - 10:49 AM) [snapback]595394[/snapback] Also- did they figure out why his was burning oil? yes. things that were wrong with the engine: 1. the oil control rings were just old and worn and got gummed up with oil so they sunk into the piston and since they didn't sit where they should oil just went right past them and got burned on the cylinder walls. the oil control rings...  Probably the same reason yours is burning oil. It's the usual cause in Toyota engines, not from worn piston rings as is normally stated. High RPM driving throws extra oil onto the cylinder walls, which makes it harder for the oil control rings anyways. And if they're clogged up, they really can't clean it off. --------------------  |

Oct 2, 2007 - 10:16 PM Oct 2, 2007 - 10:16 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

we re-shimmed the valves today. I have no pictures... it was very easy.

I'll take some of the feeler gauge and everything if anyone is interested. -------------------- |

Oct 3, 2007 - 6:47 PM Oct 3, 2007 - 6:47 PM

|

|

Enthusiast    Joined Mar 28, '04 From St.Louis Currently Offline Reputation: 15 (100%) |

i like the port jobs youve done on the head, it looks really good, but if you remember i suggested extrude hone, i just got my head done, and they are shipping it back to me soon, so i will try to take pics and show u what i meant. otherwise everything is amazing, this is a really good post about a rebuild. Keep up the good work.

--------------------  1994 GT Hatchback 1994 ST Coupe 1988 Corolla Wagon All-Trac 1999 Corvette 2008 Cobalt SS Turbo |

Oct 7, 2007 - 9:51 AM Oct 7, 2007 - 9:51 AM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

the head is back on the block, headgasket in place, cams in place and ready to be reassembled.

I cleaned up and gasket matched and polished up the intake manifold a little. I don't have pictures since my camera battery died but I'll get some next week. I ordered my oil return lines and fittings so we can drill and tap a hole for it as high as possible in the cast top part of the oil pan. -------------------- |

Oct 7, 2007 - 8:13 PM Oct 7, 2007 - 8:13 PM

|

|

|

Enthusiast    Joined May 3, '06 From New Hampshire Currently Offline Reputation: 2 (100%) |

steph, How much boost are you going to put this practically new 7A through?

--------------------  Darin H. |

Oct 7, 2007 - 10:01 PM Oct 7, 2007 - 10:01 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

probably only about 6-10psi

it should last a pretty long time, be reliable and much quicker -------------------- |

Oct 8, 2007 - 9:33 PM Oct 8, 2007 - 9:33 PM

|

|

|

Enthusiast  Joined Feb 17, '04 From michigan Currently Offline Reputation: 0 (0%) |

i just read the entire thread, great work. and i love girls that can work on cars....

omg i rebuild my head before and it was a bitch getting to those keepers and putting it back on is liek hell! gluck -------------------- 94 celica GT

92 honda prelude si<h22 swap> 93 eagle talon TSI <4G63 powered>i wish it was AWD 90 mitsu eclipse GSX<4G63 powered>SOLD LEXUS IS300< im looking for one! |

Oct 9, 2007 - 10:41 PM Oct 9, 2007 - 10:41 PM

|

|

Moderator      Joined Apr 17, '03 From Rockland NY Currently Offline Reputation: 15 (100%) |

I demand pics !

--------------------  I will return one day. |

Oct 9, 2007 - 10:53 PM Oct 9, 2007 - 10:53 PM

|

|

|

Enthusiast      Joined Mar 22, '07 From Houston, TX Currently Offline Reputation: 4 (100%) |

ok well the mod said it. you must do it

it will actually help since some ppl might plan a 7a rebuild.. -------------------- QUOTE "And, as always, your friendship, help, and dedication to the advancement of Texas Celica dominance is GREATLY appreciated. Thanks bro." -DEATH 1994 GT: V6 swap, 5speed E53 W/ LSD, All Power, now RED 1995 ST: SOLD @273k miles, Auto, all power, CarPC, White 1994 ST: Totaled, 5spd, all power, Red RIP 07/09/09 @ 241,810 1994 Lexus LS400: This is my new DD |

Oct 10, 2007 - 6:46 PM Oct 10, 2007 - 6:46 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

sorry, I haven't had time to upload and explain things.

someone asked about re-shimming the valves so I took some pics before the valve cover went on today. first you hand tighten the cams in (no need to torque them at this point) and turn it to top dead center. starting with one side first and using a feeler gauge...  do only the valves where the lobes are facing up. pull out the min and max sizes on the feeler gauge. the minimum should fit between the shim and the cam lobe...  and the maximum should not fit all the way under the lobe at all...

-------------------- |

Oct 10, 2007 - 7:01 PM Oct 10, 2007 - 7:01 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

then turn the cams half a revolution (there is a little dowel pin that goes into the cam gear that faces up when at TDC, just make that face down this time) and repeat the steps for the rest of the valves.

mark on the ledge of the valve cover which ones are in spec and which ones are out. also make sure to remember if the ones that are out of spec are too tight or too loose. at that point you have to take the cams back out. any valves that are in spec, leave alone. to take out the shim, in the second picture you can see a little notch in the cap, just pry the shim out with a little screw driver. now measure it with a micrometer like this...  and put in a shim that bigger or smaller depending on your clearance measurement with the feeler gauge. then put the cams back in and torque them down. note: in case anyone didn't know, the intake cam is spring loaded so you have to put a bolt in the threaded hole before you remove the dependent cam otherwise it will spring out of alignment. -------------------- |

Oct 10, 2007 - 7:07 PM Oct 10, 2007 - 7:07 PM

|

|

|

Enthusiast      Joined Jul 7, '03 Currently Offline Reputation: 55 (100%) |

QUOTE(hurley97 @ Oct 10, 2007 - 4:01 PM) [snapback]603776[/snapback] driver. now measure it with a micrometer like this...  LOL thats not a micrometer, but a very nice set of dial calipers.( I have 2 pairs identical to that) Very good write up. This post has been edited by 97lestyousay: Oct 10, 2007 - 7:10 PM -------------------- JDM guy made me do it.

|

Oct 10, 2007 - 7:22 PM Oct 10, 2007 - 7:22 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

GETTING CLOSE!! just putting little things back on now, there are a few things I'm going to transfer over from the motor that is in my car right now (i.e. fuel rail, alternator, power steering pump, and a few other small things)

we test fitted the turbo exhaust manifold the other day, it does need to be shaved down a little to clear the alternator bracket. I also brought my turbo into work that day to see how it sat, we did end up having to re-set the orientation of the turbo but now its perfectly the way I want it.  So now what you've all been waiting for, what I've been waiting for anyway, its pretty much done... Peter (the tech thats helping me with this) painted the valve cover, put the water pump and timing belt on for me the other day when I was late. Today we changed the distributor O-ring, put the valve cover on (with the help of a little FIPG in the sharp corners), spark plugs in, distributor, plug wires back on, put all the EGR stuff back on, cleaned up the IAC (which was stuck btw) and throttle body and put those back on, little things like that.... and heres how she sits right now.....    I know there are a few things on the back we didn't clean but thats ok, nobody is going to see them, except you guys...  So I'm pretty happy with all this, I'm excited to get this motor in. I almost want to re-think the whole waiting until 200k miles and just give in and do it at 195k.... hmmm -------------------- |

Oct 10, 2007 - 9:00 PM Oct 10, 2007 - 9:00 PM

|

|

Enthusiast      Joined May 15, '05 From Toronto Currently Offline Reputation: 4 (100%) |

looks like every things coming along great there stef. I love the look of that valve cover. You gonna do your I/C piping in black too? or silver??

|

Oct 11, 2007 - 8:26 AM Oct 11, 2007 - 8:26 AM

|

|

Enthusiast      Joined Apr 20, '06 From Florida Currently Offline Reputation: 44 (100%) |

good work stef, can't wait to see this in your car!

|

Oct 11, 2007 - 8:31 AM Oct 11, 2007 - 8:31 AM

|

|

Enthusiast      Joined Nov 12, '02 From Webster Ma. Currently Offline Reputation: 1 (100%) |

it turns me on that you know so much. knowledge is power. i like the whole black and silver scheme.

-------------------- |

|

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: January 15th, 2026 - 2:15 PM |