Jan 12, 2012 - 2:24 PM Jan 12, 2012 - 2:24 PM

|

|

|

Enthusiast      Joined May 29, '09 From Gainesville, FL Currently Offline Reputation: 17 (100%) |

To properly start a new progress thread, the new vehicle must be shown. So here we go.

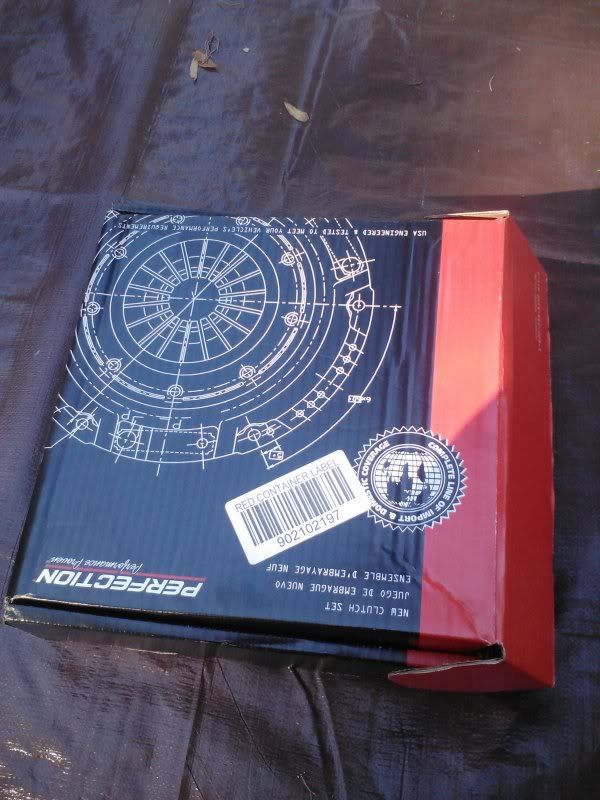

Now that is complete, we move on to this weekends fun.  Majority of items needed to accomplish the clutch change.  Prepped work area. Should be an eventful weekend. Plans for this weekend: (Let see how many I actully complete) Clutch swap over riser blocks swap over rear ssIII splitters swap over highs and projectors ( Remove OEM casing from light, and apply to projector broken casing) Covert connectors. install headunit with proper facekit wire in amp, and subs. remove rear seats Thats a hefty list, but I think I can do it. I'll damn well try. Hoping the locals have their earplugs ready. Any of you Floridians want to come to Gainesville? I'll supply beer, pizza, and California type headache relief |

|

Replies

Jan 15, 2012 - 4:10 PM Jan 15, 2012 - 4:10 PM

|

|

|

Enthusiast      Joined May 29, '09 From Gainesville, FL Currently Offline Reputation: 17 (100%) |

Aw man has it been a busy day.

All right, I need to say something here to. There are million ways I've read to get that rear mount, most circulate around "rotate the engine." I'd like the give the trophy to if I recall correctly to TRDproven for coming up with the idea to just lower the suspension crossmember. Simply loosen up the 8 or so large bolts that hold the frame, and bam you can unbolt the mount from the member, as well the bolt through the mount itself, lift it up. take member out, then simply turn the mount right out. I had a epic battle with this thing til I quit yesterday. 20 mins of "rotating" , I tried that and it was out in 5 mins. I'm even guilty in a recent thread informing someone to remove the bracket from the block whoops. As another thing I've learned today. DO NOT TENSION THE AXLE if you are trying to pop it out. See that dust shield, thats from me getting frustrated using the "tension" method I read as well. I even tried from the other side to tap the shaft, stupid I know. Didn't do it but a few and said to myself bad idea. In the end, I just tied the axle up with some metal wire, got a proper pry bar after a trip to the store, and one simple push with the prybar and my foot, with no tension. Was out so easy. 3 hours today on that...what a waste, but its out now! Now I have to determine if I can find a replacement dustshield, the axle itself is fine.  Took me some time to find all the hidden bolts and angles to remove, but she is finally out.  Cheapie to get me to the 3sgte.  Old vs. new - Studs didn't grind into the flywheel, just a slight sand, and clean up. Another "it'll do" til the swap. The didn't grind the flywheel mainly because the clutch fluid was horribly low, and air in the line when I got her. So it might have been a small blessing.  The hole! - Just a tip for any concerned, don't skip anything. Nor think this is a quick easy job because you've seen a howto with 8 steps....like my dumbass. Remove everything in the way! Its alot, i've taken alot of pictures and may use them to create a howto later on, in some detail. Oh yea, broke my slave cylinder rubber line. Was old and cracked when I zipped tied it to the harness...lol it was meant to save it from harm, not destroy it!. Well now i'm sore as hell, but semi-content on progress, put it all back together tomorrow, and wait on further parts. |

Posts in this topic

rave2n Rave's Next Progression Thread Jan 12, 2012 - 2:24 PM

rave2n Rave's Next Progression Thread Jan 12, 2012 - 2:24 PM

kurt95gt Only if i lived in fl Jan 12, 2012 - 2:45 PM

kurt95gt Only if i lived in fl Jan 12, 2012 - 2:45 PM

enderswift I look forward to this thread Jan 12, 2012 - 3:40 PM

enderswift I look forward to this thread Jan 12, 2012 - 3:40 PM

Keiri Nice pickup Rave and I'm with ender - I look f... Jan 12, 2012 - 4:08 PM

Keiri Nice pickup Rave and I'm with ender - I look f... Jan 12, 2012 - 4:08 PM

rave2n QUOTE (Keiri @ Jan 12, 2012 - 5:08 P... Jan 12, 2012 - 4:33 PM

rave2n QUOTE (Keiri @ Jan 12, 2012 - 5:08 P... Jan 12, 2012 - 4:33 PM

mak5603 Good luck on the new project! I think you coul... Jan 13, 2012 - 2:28 PM

mak5603 Good luck on the new project! I think you coul... Jan 13, 2012 - 2:28 PM

SwissFerdi Seeing as you're actually not very far from me... Jan 13, 2012 - 5:15 PM

SwissFerdi Seeing as you're actually not very far from me... Jan 13, 2012 - 5:15 PM

rave2n QUOTE (SwissFerdi @ Jan 13, 2012 - 6... Jan 13, 2012 - 5:50 PM

rave2n QUOTE (SwissFerdi @ Jan 13, 2012 - 6... Jan 13, 2012 - 5:50 PM

SwissFerdi Oh yes. I'm down. Tuesdays and thursdays are r... Jan 13, 2012 - 6:08 PM

SwissFerdi Oh yes. I'm down. Tuesdays and thursdays are r... Jan 13, 2012 - 6:08 PM

rave2n So a day of progress, but per usual I can't ge... Jan 14, 2012 - 5:37 PM

rave2n So a day of progress, but per usual I can't ge... Jan 14, 2012 - 5:37 PM

cheela WOW, that's like the price of ONE of those ite... Jan 14, 2012 - 5:42 PM

cheela WOW, that's like the price of ONE of those ite... Jan 14, 2012 - 5:42 PM

rave2n QUOTE (cheela @ Jan 14, 2012 - 6:42 ... Jan 14, 2012 - 5:46 PM

rave2n QUOTE (cheela @ Jan 14, 2012 - 6:42 ... Jan 14, 2012 - 5:46 PM

dakotahwyatt I'll giveya 120 and a six pack and 2 pizza and... Jan 14, 2012 - 9:05 PM

dakotahwyatt I'll giveya 120 and a six pack and 2 pizza and... Jan 14, 2012 - 9:05 PM

rave2n Well, a total of 30 hours and it pulls good. The c... Jan 16, 2012 - 6:47 PM

rave2n Well, a total of 30 hours and it pulls good. The c... Jan 16, 2012 - 6:47 PM

enderswift good job dude. Glad to see members sticking with c... Jan 18, 2012 - 11:18 PM

enderswift good job dude. Glad to see members sticking with c... Jan 18, 2012 - 11:18 PM

bsamps4 What are you plans for this car? Jan 18, 2012 - 11:48 PM

bsamps4 What are you plans for this car? Jan 18, 2012 - 11:48 PM

rave2n QUOTE (enderswift @ Jan 18, 2012 - 11... Jan 19, 2012 - 11:07 AM

rave2n QUOTE (enderswift @ Jan 18, 2012 - 11... Jan 19, 2012 - 11:07 AM

rave2n Little progress today, but it surely needed it.

N... Jan 20, 2012 - 5:48 PM

rave2n Little progress today, but it surely needed it.

N... Jan 20, 2012 - 5:48 PM

njccmd2002 glad to see someone loving to work on the car Jan 20, 2012 - 10:37 PM

njccmd2002 glad to see someone loving to work on the car Jan 20, 2012 - 10:37 PM

rave2n Well she did fine on her first day to work. Though... Jan 23, 2012 - 8:13 AM

rave2n Well she did fine on her first day to work. Though... Jan 23, 2012 - 8:13 AM

JasonTX QUOTE (rave2n @ Jan 20, 2012 - 5:48 ... Jan 23, 2012 - 12:53 PM

JasonTX QUOTE (rave2n @ Jan 20, 2012 - 5:48 ... Jan 23, 2012 - 12:53 PM

rave2n Day 3 on the road has yielded some insight on furt... Jan 25, 2012 - 7:43 AM

rave2n Day 3 on the road has yielded some insight on furt... Jan 25, 2012 - 7:43 AM

kurt95gt It is an odd feeling

I felt kinda wierd at first ... Jan 25, 2012 - 11:34 AM

kurt95gt It is an odd feeling

I felt kinda wierd at first ... Jan 25, 2012 - 11:34 AM

rave2n QUOTE (kurt95gt @ Jan 25, 2012 - 12... Jan 27, 2012 - 8:38 AM

rave2n QUOTE (kurt95gt @ Jan 25, 2012 - 12... Jan 27, 2012 - 8:38 AM

rave2n Well, had a little fun today.

Changed out the cl... Jan 29, 2012 - 5:08 PM

rave2n Well, had a little fun today.

Changed out the cl... Jan 29, 2012 - 5:08 PM

ricochet1490 QUOTE (rave2n @ Jan 29, 2012 - 5:08 ... Apr 22, 2012 - 7:31 PM

ricochet1490 QUOTE (rave2n @ Jan 29, 2012 - 5:08 ... Apr 22, 2012 - 7:31 PM

bsamps4 Winning! Jan 29, 2012 - 5:54 PM

bsamps4 Winning! Jan 29, 2012 - 5:54 PM

rave2n Got the audio wired up yesterday.

Was quite fun..... Feb 2, 2012 - 2:40 PM

rave2n Got the audio wired up yesterday.

Was quite fun..... Feb 2, 2012 - 2:40 PM

rave2n Rims painted with Plastidip, and new front caliper... Feb 21, 2012 - 11:20 AM

rave2n Rims painted with Plastidip, and new front caliper... Feb 21, 2012 - 11:20 AM

TRD_Ian dude nice work its looking good, i just went throu... Feb 21, 2012 - 7:44 PM

TRD_Ian dude nice work its looking good, i just went throu... Feb 21, 2012 - 7:44 PM

rave2n QUOTE (TRD_Ian @ Feb 21, 2012 - 8:44... Feb 22, 2012 - 9:52 AM

rave2n QUOTE (TRD_Ian @ Feb 21, 2012 - 8:44... Feb 22, 2012 - 9:52 AM

rave2n Been a busy weekend.

Riser blocks, applied new cl... Mar 4, 2012 - 4:15 PM

rave2n Been a busy weekend.

Riser blocks, applied new cl... Mar 4, 2012 - 4:15 PM

enderswift good stuff Mar 5, 2012 - 1:14 AM

enderswift good stuff Mar 5, 2012 - 1:14 AM

rave2n Finally got the audio situated correctly. Just wok... Apr 22, 2012 - 1:18 PM

rave2n Finally got the audio situated correctly. Just wok... Apr 22, 2012 - 1:18 PM

SwissFerdi Bittersweet. At least it found a good home. ... Apr 22, 2012 - 6:57 PM

SwissFerdi Bittersweet. At least it found a good home. ... Apr 22, 2012 - 6:57 PM

mak5603 Damn bro, the 20 oz red bulls, you go hard, haha. ... Apr 22, 2012 - 7:10 PM

mak5603 Damn bro, the 20 oz red bulls, you go hard, haha. ... Apr 22, 2012 - 7:10 PM

Tigawoods coming along quite well! Apr 23, 2012 - 6:17 AM

Tigawoods coming along quite well! Apr 23, 2012 - 6:17 AM

rave2n QUOTE (SwissFerdi @ Apr 22, 2012 - 7... Apr 23, 2012 - 12:26 PM

rave2n QUOTE (SwissFerdi @ Apr 22, 2012 - 7... Apr 23, 2012 - 12:26 PM

rave2n Feeling motivated again. Took a little while with ... Jul 3, 2012 - 11:58 AM

rave2n Feeling motivated again. Took a little while with ... Jul 3, 2012 - 11:58 AM

SwissFerdi RE: Rave's Next Progression Thread Jul 3, 2012 - 2:04 PM

SwissFerdi RE: Rave's Next Progression Thread Jul 3, 2012 - 2:04 PM

rave2n Loading up.

Only got it about 10 feet in the ya... Jul 4, 2012 - 1:01 PM

rave2n Loading up.

Only got it about 10 feet in the ya... Jul 4, 2012 - 1:01 PM

rave2n Got the engine behind the house, now to take the A... Jul 7, 2012 - 1:41 PM

rave2n Got the engine behind the house, now to take the A... Jul 7, 2012 - 1:41 PM

SwissFerdi And, did you? Jul 8, 2012 - 9:00 AM

SwissFerdi And, did you? Jul 8, 2012 - 9:00 AM

rave2n QUOTE (SwissFerdi @ Jul 8, 2012 - 10... Jul 8, 2012 - 11:06 AM

rave2n QUOTE (SwissFerdi @ Jul 8, 2012 - 10... Jul 8, 2012 - 11:06 AM

SwissFerdi RE: Rave's Next Progression Thread Jul 8, 2012 - 11:08 AM

SwissFerdi RE: Rave's Next Progression Thread Jul 8, 2012 - 11:08 AM

rave2n Bah, home depot did not carry the bolts, and all t... Jul 8, 2012 - 1:22 PM

rave2n Bah, home depot did not carry the bolts, and all t... Jul 8, 2012 - 1:22 PM

enderswift ah yes the bolts. I ran into the same problem lol.... Jul 8, 2012 - 7:54 PM

enderswift ah yes the bolts. I ran into the same problem lol.... Jul 8, 2012 - 7:54 PM

rave2n QUOTE (enderswift @ Jul 8, 2012 - 7... Jul 9, 2012 - 7:59 AM

rave2n QUOTE (enderswift @ Jul 8, 2012 - 7... Jul 9, 2012 - 7:59 AM

rave2n Win!

Felt a little bad for the shop owner, yo... Jul 9, 2012 - 4:00 PM

rave2n Win!

Felt a little bad for the shop owner, yo... Jul 9, 2012 - 4:00 PM

rave2n Want to update you folks, but these flywheel bolts... Jul 12, 2012 - 10:28 AM

rave2n Want to update you folks, but these flywheel bolts... Jul 12, 2012 - 10:28 AM

enderswift Buy an impact wrench and a compressor. Trust me, i... Jul 12, 2012 - 3:33 PM

enderswift Buy an impact wrench and a compressor. Trust me, i... Jul 12, 2012 - 3:33 PM

rave2n QUOTE (enderswift @ Jul 12, 2012 - 3... Jul 13, 2012 - 3:40 PM

rave2n QUOTE (enderswift @ Jul 12, 2012 - 3... Jul 13, 2012 - 3:40 PM

jordisonjr QUOTE (rave2n @ Jul 13, 2012 - 3:40 ... Jul 13, 2012 - 3:53 PM

jordisonjr QUOTE (rave2n @ Jul 13, 2012 - 3:40 ... Jul 13, 2012 - 3:53 PM

rave2n I know some of these updates may seem pointless an... Jul 13, 2012 - 6:55 PM

rave2n I know some of these updates may seem pointless an... Jul 13, 2012 - 6:55 PM

mak5603 Yeah dude, getting the AWD tranny off while on the... Jul 15, 2012 - 12:49 PM

mak5603 Yeah dude, getting the AWD tranny off while on the... Jul 15, 2012 - 12:49 PM

rave2n Got a little work done on the 3s. Just tearing thi... Jul 15, 2012 - 3:02 PM

rave2n Got a little work done on the 3s. Just tearing thi... Jul 15, 2012 - 3:02 PM

jcbass7 looking good, keep up the progress

ps: I think... Jul 15, 2012 - 4:47 PM

jcbass7 looking good, keep up the progress

ps: I think... Jul 15, 2012 - 4:47 PM

rave2n Well, got the OEM downpipe off, and a few other ti... Jul 16, 2012 - 5:37 PM

rave2n Well, got the OEM downpipe off, and a few other ti... Jul 16, 2012 - 5:37 PM

Sebby U're doing very well man, nice thread.Good luc... Jul 17, 2012 - 5:50 AM

Sebby U're doing very well man, nice thread.Good luc... Jul 17, 2012 - 5:50 AM

rave2n QUOTE (Sebby @ Jul 17, 2012 - 5:50 A... Jul 18, 2012 - 10:24 AM

rave2n QUOTE (Sebby @ Jul 17, 2012 - 5:50 A... Jul 18, 2012 - 10:24 AM

enderswift koyo is a very good brand. They make our oem beari... Jul 18, 2012 - 5:18 PM

enderswift koyo is a very good brand. They make our oem beari... Jul 18, 2012 - 5:18 PM

rave2n QUOTE (enderswift @ Jul 18, 2012 - 5... Jul 19, 2012 - 4:57 PM

rave2n QUOTE (enderswift @ Jul 18, 2012 - 5... Jul 19, 2012 - 4:57 PM

Syaoran QUOTE (rave2n @ Jul 19, 2012 - 5:57 ... Jul 19, 2012 - 9:12 PM

Syaoran QUOTE (rave2n @ Jul 19, 2012 - 5:57 ... Jul 19, 2012 - 9:12 PM

rave2n QUOTE (Syaoran @ Jul 19, 2012 - 10:1... Jul 20, 2012 - 8:27 AM

rave2n QUOTE (Syaoran @ Jul 19, 2012 - 10:1... Jul 20, 2012 - 8:27 AM

kurt95gt If you go that route make sure its a big one

Mine... Jul 20, 2012 - 11:42 AM

kurt95gt If you go that route make sure its a big one

Mine... Jul 20, 2012 - 11:42 AM

rave2n QUOTE (kurt95gt @ Jul 20, 2012 - 12... Jul 20, 2012 - 11:56 AM

rave2n QUOTE (kurt95gt @ Jul 20, 2012 - 12... Jul 20, 2012 - 11:56 AM

rave2n VICTORY!

Alrighty, my solution was simple, an... Jul 20, 2012 - 5:45 PM

rave2n VICTORY!

Alrighty, my solution was simple, an... Jul 20, 2012 - 5:45 PM

SwissFerdi RE: Rave's Next Progression Thread Jul 20, 2012 - 5:57 PM

SwissFerdi RE: Rave's Next Progression Thread Jul 20, 2012 - 5:57 PM

rave2n Time get some shiz done today.

Bolt from hell... Jul 21, 2012 - 8:26 AM

rave2n Time get some shiz done today.

Bolt from hell... Jul 21, 2012 - 8:26 AM

rave2n Moar progress!

Plugs don't look fouled ... Jul 21, 2012 - 10:55 AM

rave2n Moar progress!

Plugs don't look fouled ... Jul 21, 2012 - 10:55 AM

rave2n e154f sold yesterday.

Time to do a little shoppi... Jul 25, 2012 - 8:01 AM

rave2n e154f sold yesterday.

Time to do a little shoppi... Jul 25, 2012 - 8:01 AM

rave2n Bearings and belt came in the other day.

tension... Jul 30, 2012 - 9:37 AM

rave2n Bearings and belt came in the other day.

tension... Jul 30, 2012 - 9:37 AM

ricochet1490 outstanding work! way to keep at it for sure... Jul 30, 2012 - 2:39 PM

ricochet1490 outstanding work! way to keep at it for sure... Jul 30, 2012 - 2:39 PM

rave2n QUOTE (ricochet1490 @ Jul 30, 2012 - 2... Aug 2, 2012 - 8:13 AM

rave2n QUOTE (ricochet1490 @ Jul 30, 2012 - 2... Aug 2, 2012 - 8:13 AM

rave2n Cleaning up some items while I wait for 1 gasket... Aug 4, 2012 - 12:43 PM

rave2n Cleaning up some items while I wait for 1 gasket... Aug 4, 2012 - 12:43 PM

SwissFerdi In your words, getting it done. Cool stuff, having... Aug 4, 2012 - 12:54 PM

SwissFerdi In your words, getting it done. Cool stuff, having... Aug 4, 2012 - 12:54 PM

rave2n QUOTE (SwissFerdi @ Aug 4, 2012 - 1... Aug 4, 2012 - 3:15 PM

rave2n QUOTE (SwissFerdi @ Aug 4, 2012 - 1... Aug 4, 2012 - 3:15 PM

SwissFerdi I'm almost more excited about seeing your 3S g... Aug 4, 2012 - 4:26 PM

SwissFerdi I'm almost more excited about seeing your 3S g... Aug 4, 2012 - 4:26 PM

njccmd2002 some of that gunk, can be better handled with pine... Aug 4, 2012 - 9:00 PM

njccmd2002 some of that gunk, can be better handled with pine... Aug 4, 2012 - 9:00 PM

rave2n Got some more done today.

Cleaned all surfaces, a... Aug 7, 2012 - 3:53 PM

rave2n Got some more done today.

Cleaned all surfaces, a... Aug 7, 2012 - 3:53 PM

rave2n Getting there, timing slightly off, but I know wel... Aug 9, 2012 - 3:57 PM

rave2n Getting there, timing slightly off, but I know wel... Aug 9, 2012 - 3:57 PM

rave2n Finally got the timing right. Had to pull the tens... Aug 11, 2012 - 3:06 PM

rave2n Finally got the timing right. Had to pull the tens... Aug 11, 2012 - 3:06 PM

rave2n A little bit of progress today...

Some more gen... Aug 16, 2012 - 6:10 PM

rave2n A little bit of progress today...

Some more gen... Aug 16, 2012 - 6:10 PM

rave2n Argh so busy right now...

Can't get anything ... Sep 10, 2012 - 12:01 PM

rave2n Argh so busy right now...

Can't get anything ... Sep 10, 2012 - 12:01 PM

enderswift keep it up dude, it's all gonna be worth it in... Sep 10, 2012 - 12:43 PM

enderswift keep it up dude, it's all gonna be worth it in... Sep 10, 2012 - 12:43 PM

richee3 Getting closer! You'll have it swapped in ... Sep 26, 2012 - 4:21 PM

richee3 Getting closer! You'll have it swapped in ... Sep 26, 2012 - 4:21 PM

rave2n QUOTE (richee3 @ Sep 26, 2012 - 5:21... Sep 27, 2012 - 12:46 PM

rave2n QUOTE (richee3 @ Sep 26, 2012 - 5:21... Sep 27, 2012 - 12:46 PM

rave2n A freshly rebuilt S54 Transmission. Free of charge... Sep 28, 2012 - 10:47 AM

rave2n A freshly rebuilt S54 Transmission. Free of charge... Sep 28, 2012 - 10:47 AM

richee3 FREE S54?!?! Throw an MR-S LSD in there an... Sep 28, 2012 - 11:12 AM

richee3 FREE S54?!?! Throw an MR-S LSD in there an... Sep 28, 2012 - 11:12 AM

SwissFerdi ^ It's deserved, he gave me an excellent deal ... Sep 28, 2012 - 11:24 AM

SwissFerdi ^ It's deserved, he gave me an excellent deal ... Sep 28, 2012 - 11:24 AM

rave2n QUOTE (richee3 @ Sep 28, 2012 - 11:1... Sep 30, 2012 - 9:37 AM

rave2n QUOTE (richee3 @ Sep 28, 2012 - 11:1... Sep 30, 2012 - 9:37 AM

rave2n Putting the skirts on, and rear splitters. Also fi... Nov 4, 2012 - 11:59 AM

rave2n Putting the skirts on, and rear splitters. Also fi... Nov 4, 2012 - 11:59 AM

rave2n Well got the skirts and rear splitters put on. As ... Nov 14, 2012 - 8:39 AM

rave2n Well got the skirts and rear splitters put on. As ... Nov 14, 2012 - 8:39 AM

Zake QUOTE (rave2n @ Nov 14, 2012 - 7:39 ... Nov 23, 2012 - 11:48 AM

Zake QUOTE (rave2n @ Nov 14, 2012 - 7:39 ... Nov 23, 2012 - 11:48 AM

SwissFerdi I spy the ST! Color looks much better. Nov 14, 2012 - 9:27 AM

SwissFerdi I spy the ST! Color looks much better. Nov 14, 2012 - 9:27 AM

kurt95gt I say put it back on Nov 14, 2012 - 10:54 AM

kurt95gt I say put it back on Nov 14, 2012 - 10:54 AM

enderswift x2

paint looks great Nov 15, 2012 - 8:44 PM

enderswift x2

paint looks great Nov 15, 2012 - 8:44 PM

njccmd2002 RE: Rave's Next Progression Thread Nov 16, 2012 - 1:30 AM

njccmd2002 RE: Rave's Next Progression Thread Nov 16, 2012 - 1:30 AM

rave2n QUOTE (njccmd2002 @ Nov 16, 2012 - 1... Nov 17, 2012 - 3:44 PM

rave2n QUOTE (njccmd2002 @ Nov 16, 2012 - 1... Nov 17, 2012 - 3:44 PM  |

2 User(s) are reading this topic (2 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: January 12th, 2026 - 4:51 AM |