Jun 1, 2010 - 2:11 PM Jun 1, 2010 - 2:11 PM

|

|

Enthusiast      Joined Feb 7, '07 From Portland, Oregon Currently Offline Reputation: 67 (96%) |

Looking into getting my cams ground, keeping stock internals for the time being. Two questions: if I have my cams ground, do I need to re-shim the valves or any of that sort of stuff, or is this basically a "drop in"? I'm looking for more of an overall performance grind, with the intention of turboing the 7A in the hopefully not too distant future. So how much should I have ground? I know webcams has a numbered grind system, but I'm looking at having them done locally, and it'd be nice to sound at least a *little* bit like I know what I'm talking about.

--------------------  |

|

Replies

Jun 3, 2010 - 7:56 PM Jun 3, 2010 - 7:56 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

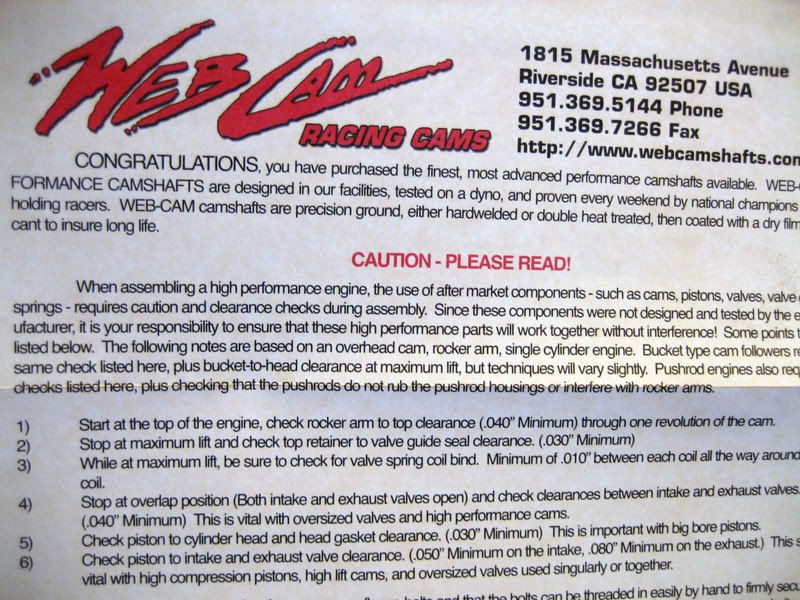

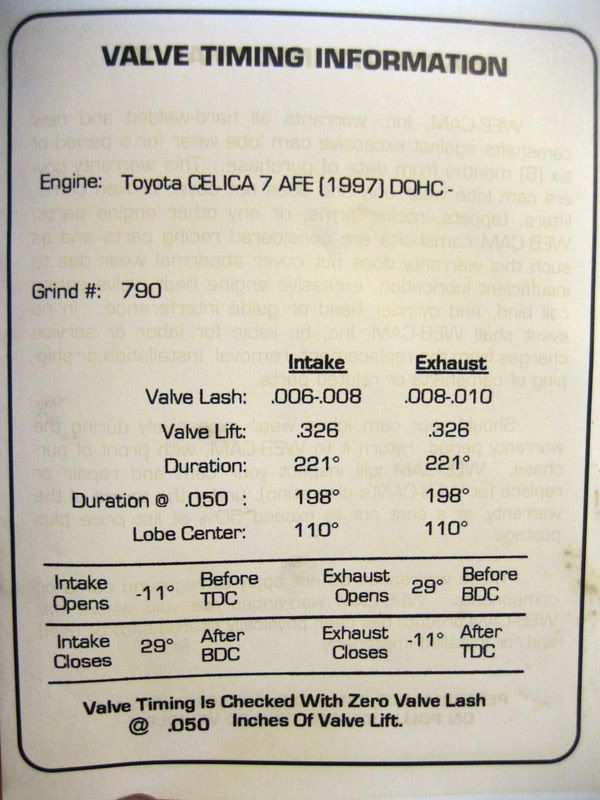

I'm pretty sure I have a spare set of cams in the basement if you want them, that will reduce down time while you have them re-ground. Mine are from Web Cams, they don't specifically make a set for the 7A so you have to have them custom made. I had them custom ground based on the fact that I was going to turbo the motor in the near future. I did drive the car with the motor stock and just the cams for like 13k miles. They basically didn't do very much on the low end (since the addition of a turbo would increase low end power) but it held out the power all the way to redline as opposed to dropping off in the mid rpm range.

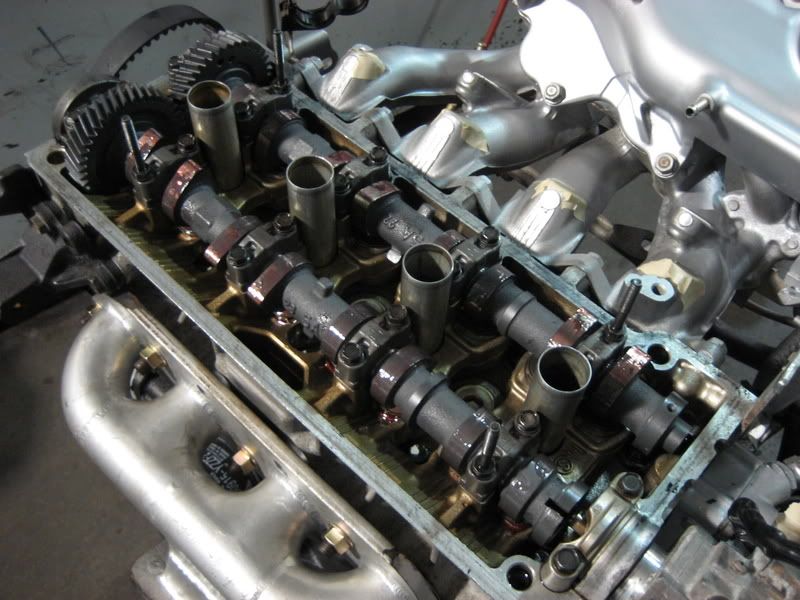

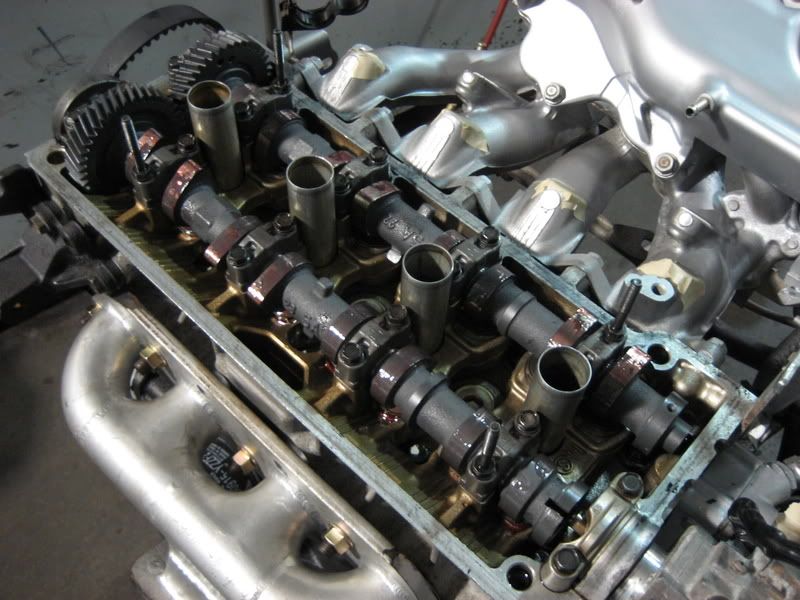

All the following info is from my engine rebuild thread when I installed the cams, hope it helps a little...       someone asked about re-shimming the valves so I took some pics before the valve cover went on today.

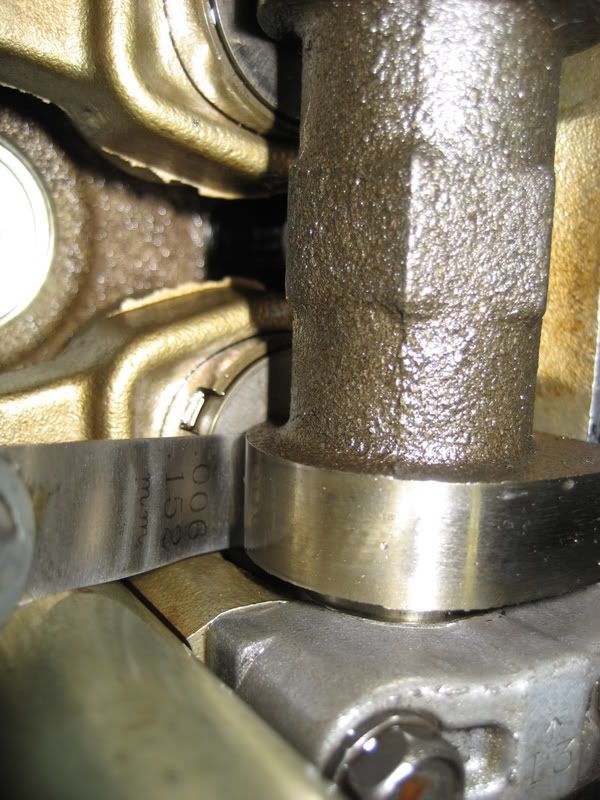

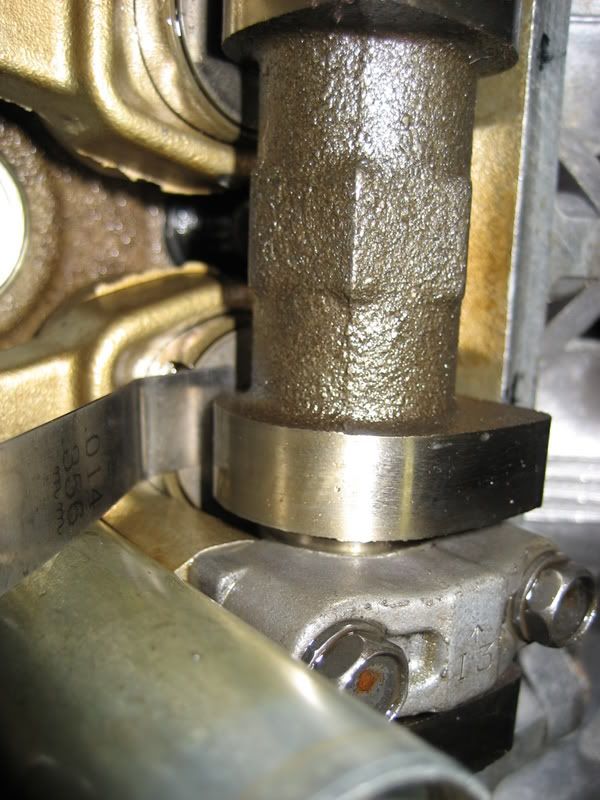

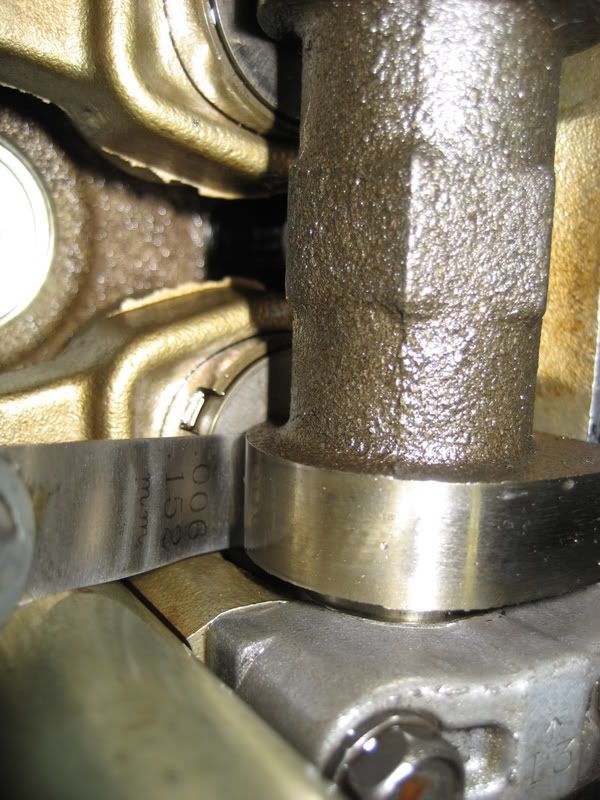

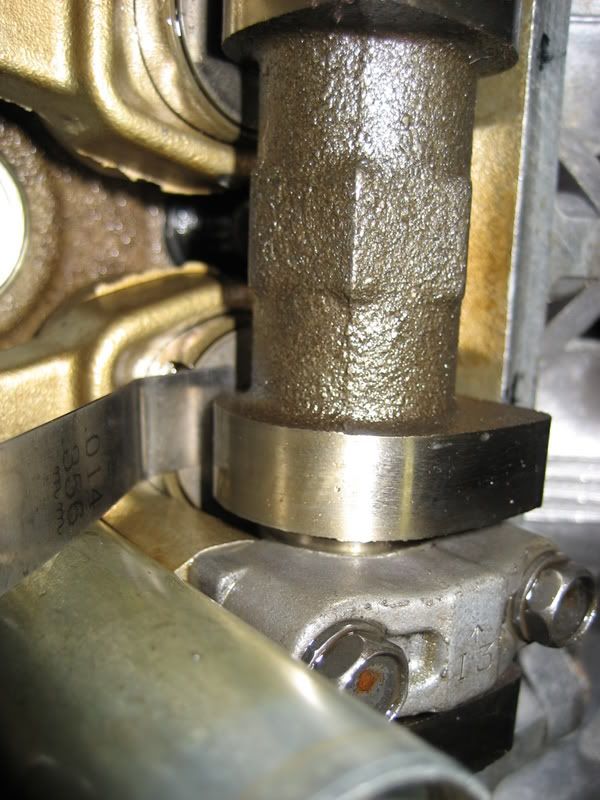

first you hand tighten the cams in (no need to torque them at this point) and turn it to top dead center. starting with one side first and using a feeler gauge...  do only the valves where the lobes are facing up. pull out the min and max sizes on the feeler gauge. the minimum should fit between the shim and the cam lobe...  and the maximum should not fit all the way under the lobe at all...  -------------------- |

Jun 7, 2010 - 12:04 PM Jun 7, 2010 - 12:04 PM

|

|

Enthusiast      Joined Feb 7, '07 From Portland, Oregon Currently Offline Reputation: 67 (96%) |

Not only does this info help, it's actually what's inspired me to do this in the first place

I've been following your build(s) now since you started them, and have recently been referring back to your build thread quite frequently to study it for info, tips and ideas. I check Craigslist almost daily to look for Celica parts, which is how I stumbled on the post for the free 7AFE head. I appreciate the offer on the cams, I was actually gonna PM you if the free head (heh heh, I said free head) thing didn't work out, but I was able to pick it up on Saturday, so now I've got the cams & don't have to worry about down time! The head was described to me as most likely being warped; original owner blew the gasket so he just replaced the entire head. Makes no difference to me if the head is warped though, it's an opportunity to study it and learn it. I'll keep the cams (obviously) and the valve cover (yay!) and get a few bucks for scrap metal on the rest. So I'm probably NOT going to send the cams to Web Cams, only because there's a few places local to me that can do it, and I kinda want to have them done in time for the Cali meet at the end of the month. So the ultimate goal with these is yes, to increase top end performance. Because the low end will be covered with the turbo build. If I print out that specs sheet you posted and take it to the place I'm having the cams done at, it contains enough information for them to basically replicate that, yes? Obviously the grind number isn't relevant to them, but the degreeing info is where it's at, correct? I'm pretty sure I have a spare set of cams in the basement if you want them, that will reduce down time while you have them re-ground. Mine are from Web Cams, they don't specifically make a set for the 7A so you have to have them custom made. I had them custom ground based on the fact that I was going to turbo the motor in the near future. I did drive the car with the motor stock and just the cams for like 13k miles. They basically didn't do very much on the low end (since the addition of a turbo would increase low end power) but it held out the power all the way to redline as opposed to dropping off in the mid rpm range. All the following info is from my engine rebuild thread when I installed the cams, hope it helps a little...       someone asked about re-shimming the valves so I took some pics before the valve cover went on today. first you hand tighten the cams in (no need to torque them at this point) and turn it to top dead center. starting with one side first and using a feeler gauge...  do only the valves where the lobes are facing up. pull out the min and max sizes on the feeler gauge. the minimum should fit between the shim and the cam lobe...  and the maximum should not fit all the way under the lobe at all...  --------------------  |

Posts in this topic

GriffGirl 7AFE camshaft grind Jun 1, 2010 - 2:11 PM

GriffGirl 7AFE camshaft grind Jun 1, 2010 - 2:11 PM

95CelicaST Delta camshaft in Tacoma. Go over on pstoc and sho... Jun 1, 2010 - 2:25 PM

95CelicaST Delta camshaft in Tacoma. Go over on pstoc and sho... Jun 1, 2010 - 2:25 PM

GriffGirl QUOTE (95CelicaST @ Jun 1, 2010 - 12... Jun 1, 2010 - 6:35 PM

GriffGirl QUOTE (95CelicaST @ Jun 1, 2010 - 12... Jun 1, 2010 - 6:35 PM

Batman722 you will have to re-shim the valves. Jun 1, 2010 - 3:14 PM

Batman722 you will have to re-shim the valves. Jun 1, 2010 - 3:14 PM

dans_st I haven't looked into it on my boost 7A but fr... Jun 3, 2010 - 7:20 PM

dans_st I haven't looked into it on my boost 7A but fr... Jun 3, 2010 - 7:20 PM

Johnnyny QUOTE (hurley97 @ Dec 11, 2007 - 8:2... Jun 3, 2010 - 8:11 PM

Johnnyny QUOTE (hurley97 @ Dec 11, 2007 - 8:2... Jun 3, 2010 - 8:11 PM

hurley97 QUOTE (GriffGirl @ Jun 7, 2010 - 1:0... Jun 8, 2010 - 4:13 PM

hurley97 QUOTE (GriffGirl @ Jun 7, 2010 - 1:0... Jun 8, 2010 - 4:13 PM

Smaay Michelle you need to save your $$$ ... Jun 9, 2010 - 3:26 PM

Smaay Michelle you need to save your $$$ ... Jun 9, 2010 - 3:26 PM

GriffGirl QUOTE (Smaay @ Jun 9, 2010 - 1:26 PM... Jun 11, 2010 - 3:31 PM

GriffGirl QUOTE (Smaay @ Jun 9, 2010 - 1:26 PM... Jun 11, 2010 - 3:31 PM  |

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: January 4th, 2026 - 12:40 PM |